HY-TRAX® Fluid Sampling Systems

In the past, unplanned equipment downtime and its associated costs resulted from a lack of visibility to real-time hydraulic fluid cleanliness conditions. Limited real-time condition monitoring information has plagued OEM’s Fleet Managers and Maintenance Personnel for years.

In the past, unplanned equipment downtime and its associated costs resulted from a lack of visibility to real-time hydraulic fluid cleanliness conditions. Limited real-time condition monitoring information has plagued OEM’s Fleet Managers and Maintenance Personnel for years.

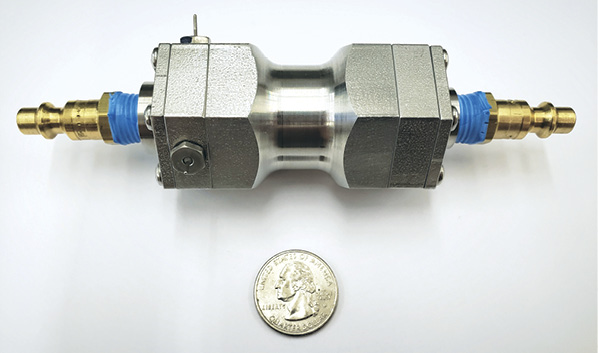

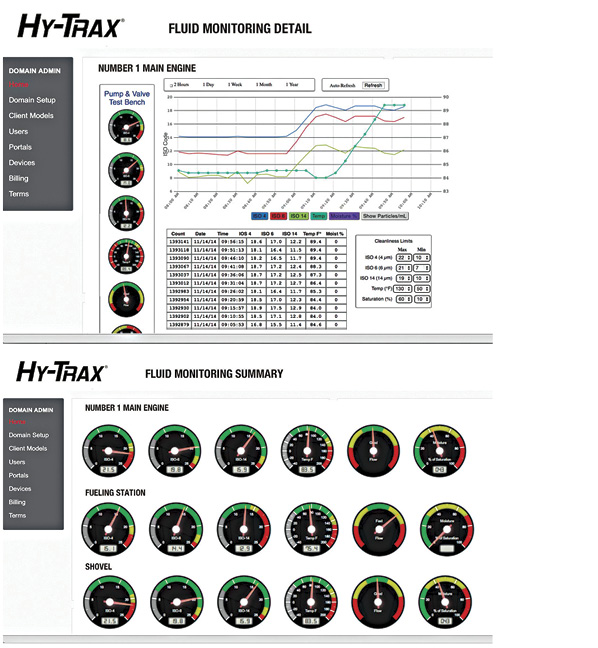

Schroeder Industries released an advanced, compact, plug-and-play, on-board particle counting system, the patent-pending HY-TRAX® fluid sampling system. The system utilizes a telematics solution, allowing users to remotely monitor cleanliness of the hydraulic fluid, along with data transfer through GSM cellular network with data displayed through a secure web-based dashboard. Real-time data allows the invested parties to track, trend, and predict downtime on equipment, leading to increased uptime and productivity. With multiple options offered, the telematics module automatically controls the continuous-duty VSD sampling pump. This feature ensures exact particle counts by maintaining correct flow and pressure through the sensor at all times.

The unit provides hardware, web and mobile interfaces, data trending, and reporting. The system has an alarm feature that allows users to set particle count and water saturation limits (with optional water sensor). When set limits are exceeded, the unit will send a text message to users notifying of excessive contamination. The web interface shows all system information in a simple layout. In real-time, the particle counts and water saturation levels are clearly displayed graphically, along with a table and gauges, allowing users to track and trend (days, months, and years) of data to move from reactionary-based maintenance to predictive.

The HY-TRAX® unit is a preventive/predictive maintenance program optimizing the availability of machines, fluid technology and systems, while reducing operating costs and warranty claims.

For more information, visit www.schroederindustries.com.