Freudenberg’s Self-Diagnosing ‘Smart Seals’

From Freudenberg Sealing Technologies.

Freudenberg Sealing Technologies recently validated the performance capabilities of intelligent seals it has under development.

In addition to their core function, the seals handle tasks sensor applications and can monitor their own wear. As a result, they enhance the reliability of machines and systems by providing performance and safety data. That helps eliminate mechanical failures and unanticipated downtime. A new feasibility study by Freudenberg recently verified the benefits of these sealing functions, the company said.

Seals have several important functions, including preventing contamination, creating temperature and pressure safeguards, and protecting the external environment from accidental leaks and spills. By maintaining an impervious barrier between their external and internal environments, the seals protect machinery and systems from dirt, grime, and temperature and pressure fluctuations. They further prevent aggressive fluids and chemicals from polluting their surroundings. In the future, Freudenberg intelligent seals can significantly expand this important core task, as the seal is also a sensor that applies built-in functionality and becomes a “smart seal.”

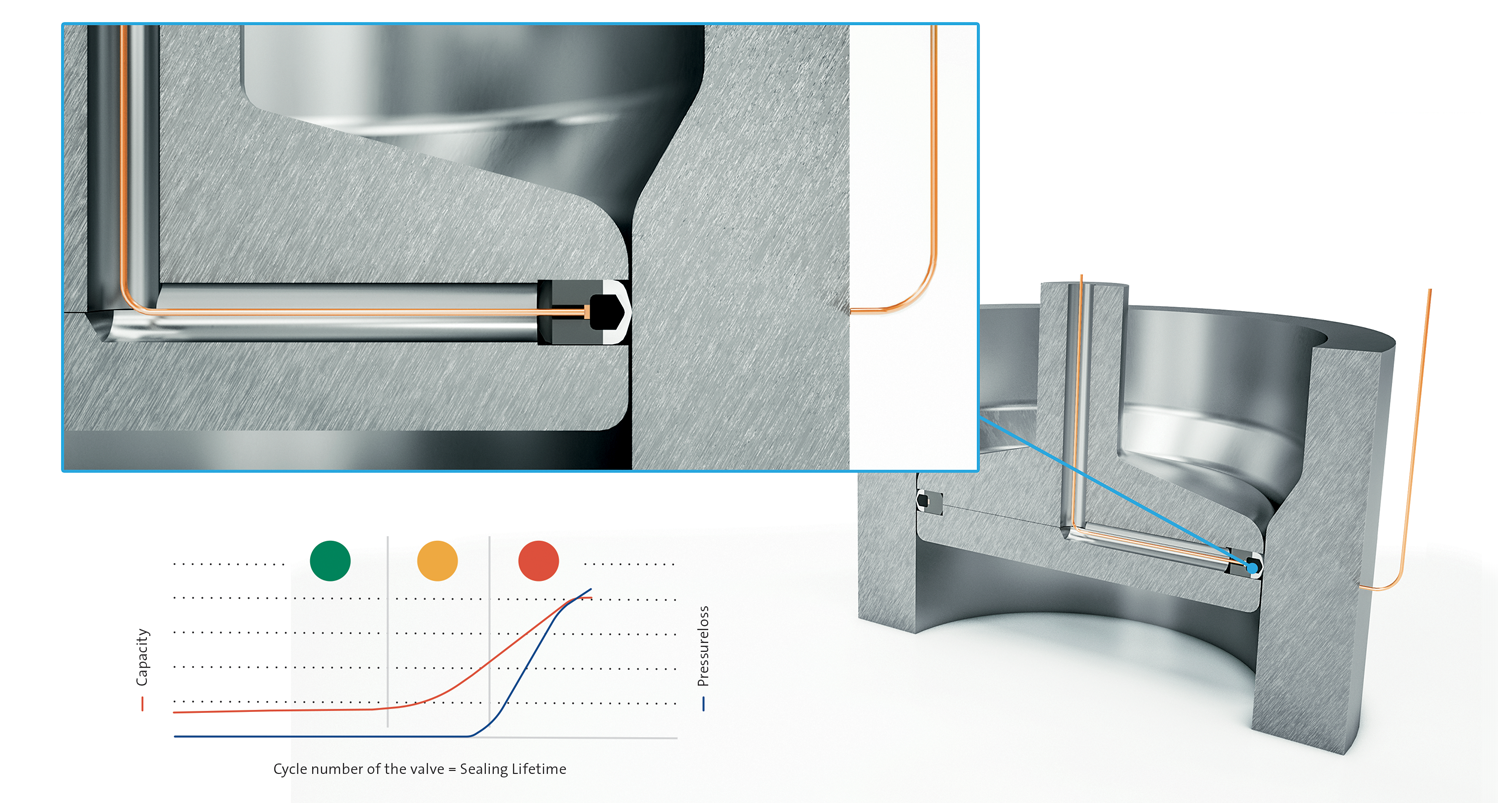

Freudenberg is developing an intelligent rod seal that forms a capacitor with outer layers made of an electrically insulating elastomer, an inner layer of an electrically conductive elastomer, and a metallic housing wall. If the successive abrasions of the insulating layer cause the seal to wear down, the distance between the electrically conductive layer to the metallic housing decreases while the capacitance rises. This makes it possible to obtain a condition measurement, which indicates the service life of the rod seal if the wear remains constant.

This offers considerable advantages. Maintenance times can be scheduled reliably in advance. Such predictions prevent follow-up costs caused by leakage and lower the risk of contaminating an entire batch. Another benefit is that, during its service life, the seal need not be replaced prematurely, optimizing operating costs and providing a sustainable solution.

The technical concept

Freudenberg has developed sealing materials and a smart rod seal that meet the performance requirements of a conventional rod seal, including acid and base resistance, standards, service life, and manufacturability.

Freudenberg’s smart-seal feasibility study offers proof of a valid concept that offers benefits. The comprehensive study confirms that the sensor concept works in real-life situations. The simulation of the capacitor principle gave the developers important answers.

“The change in capacitance informatively describes the wear of the seal lip,” said Olaf Nahrwold, Freudenberg development engineer. “When the seal reaches the limit of its wear and tear, the capacitance increases significantly and approaches an exponential progression. A failure of the seal, and thus an imminent leakage, can be prevented in a timely manner. To achieve this, we had to tackle several challenges, such as adapting the component geometries and developing the corresponding measurement software, which has proven to be very robust.”

Extensive tests in real application settings were key components of the feasibility study. In laboratory practice, they prove the full function of the innovative seal exactly as intended. Installed in a standard valve, it reliably seals the system in both dry and aqueous environments; at the same time, it continuously provides real-time measurement data about its own remaining service life.

The result is substantiated by comparing all capacitive measurements with a real mechanical leakage. To this end, overpressure is applied to the valve. As long as it remains constant, the system is free of leaks. All tests yielded a rise in capacitance before any measurable leakage. The system accurately captures the state of wear, which enables it to predict when the seal will fail.

“These positive results of the feasibility study are an important condition for the possible everyday use of intelligent seals in many application scenarios,” said Boris Traber, manager of Freudenberg’s global materials predevelopment. “We also examined how this concept can be transferred to PTFE seals, such as those used in hydraulic applications with increased requirements for thermal and mechanical resistance at high pressures. These results are also highly encouraging.”

Smart seals advantages

The concept may sound simple, but experts have performed considerable research and development work on it in recent years. The immense know-how is reflected in the materials and the fundamental structure of the intelligent seal. As to production-specific implementation, every seal made by Freudenberg is a high-precision component. For smart seals in large-scale series production, this capability makes it possible for a company to ensure the sensor quality required for the application.

On the current status of this technology, Traber said: “Given that there are still various unanswered questions, it will probably still take some time before a specific practical application is identified. The sensor information will also have to be implemented in the plant control systems so that actions can be triggered based on the data. The best way to clear up these questions is through application projects with their specific requirements.”

For more information, visit www.freudenberg.com.