HAWE Hydraulik Launches Products for Wind Turbines

HAWE Hydraulik recently released three new products, two of them for control of wind turbines.

Brake control for wind turbines

In the event of an emergency or planned maintenance, the fast shaft of the gearbox in a wind turbine must be braked safely and kept safe after stopping. For this purpose, a disc brake is positioned on the shaft in medium and large wind turbines. It can be reliably triggered and operated by a hydraulic power pack with attached manifold. Depending on the size of the brakes, HAWE Hydraulik quickly and easily designs the right compact hydraulic power pack from the modular system.

Directly flanged to the hydraulic power pack is the manifold, which is carried out in the HAWE Hydraulik solution with directional seated valves. You can choose between control blocks with screw-in valves or the service-friendly functional modular design. Due to their design, the directional seated valves integrated in both designs hold the brake in the tightened position for up to eight days, even in the event of a failed electric power supply. In addition, a hand pump can be attached directly to the hydraulic power pack. With it, the brake can be activated manually in the event of maintenance.

With its compact power units, HAWE Hydraulik builds customer-specific solutions that can also be mounted directly on the rotor brake, thus avoiding unnecessary cable lengths. The power units can be arranged both horizontally and standing. As required in various countries of operation, they are suitable for cold climates and UL approved on request.

Pitch control in wind turbines

Pitch controls and pitch drives are used to reliably adjust the blade angle to the wind in wind turbines. These are also a guarantee for the best possible energy yield from wind power and must work reliably over the entire service life of the plant. Current development trends show a continuous increase in pitch activity. At the same time, the functionality of the drives has a considerable influence on the service life of other components such as the tower and foundation.

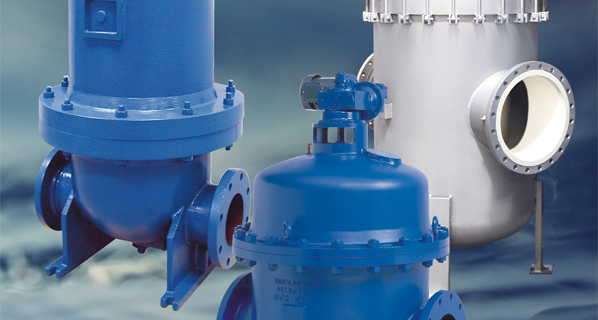

HAWE Energy Solutions, a subsidiary of HAWE Hydraulik, has developed a pitch bearing unit consisting of blade bearing and pitch drive together with Thyssen Krupp Rothe Erde. The hydraulic pitch drive (pitch module) is integrated directly into the blade bearing as a prefabricated and tested unit. This combination then represents a ready-to-install system solution for the customer. The pitch module can also be an independent component.

The pitch module consists of the pitch cylinders for turning the blade, hydraulic piston accumulators for demand-oriented power supply, a manifold with a highly dynamic proportional valve, and the necessary piping. The pitch module can be used for both electrical and hydraulic pitch systems.

Due to the modular design, various constructive designs are possible. Three different ones have already been constructively implemented at HAWE Energy Solutions. This makes it possible to implement customer-specific solutions for every size of wind turbine. The preassembled delivery also reduces logistics costs and assembly times.

The PowerBox

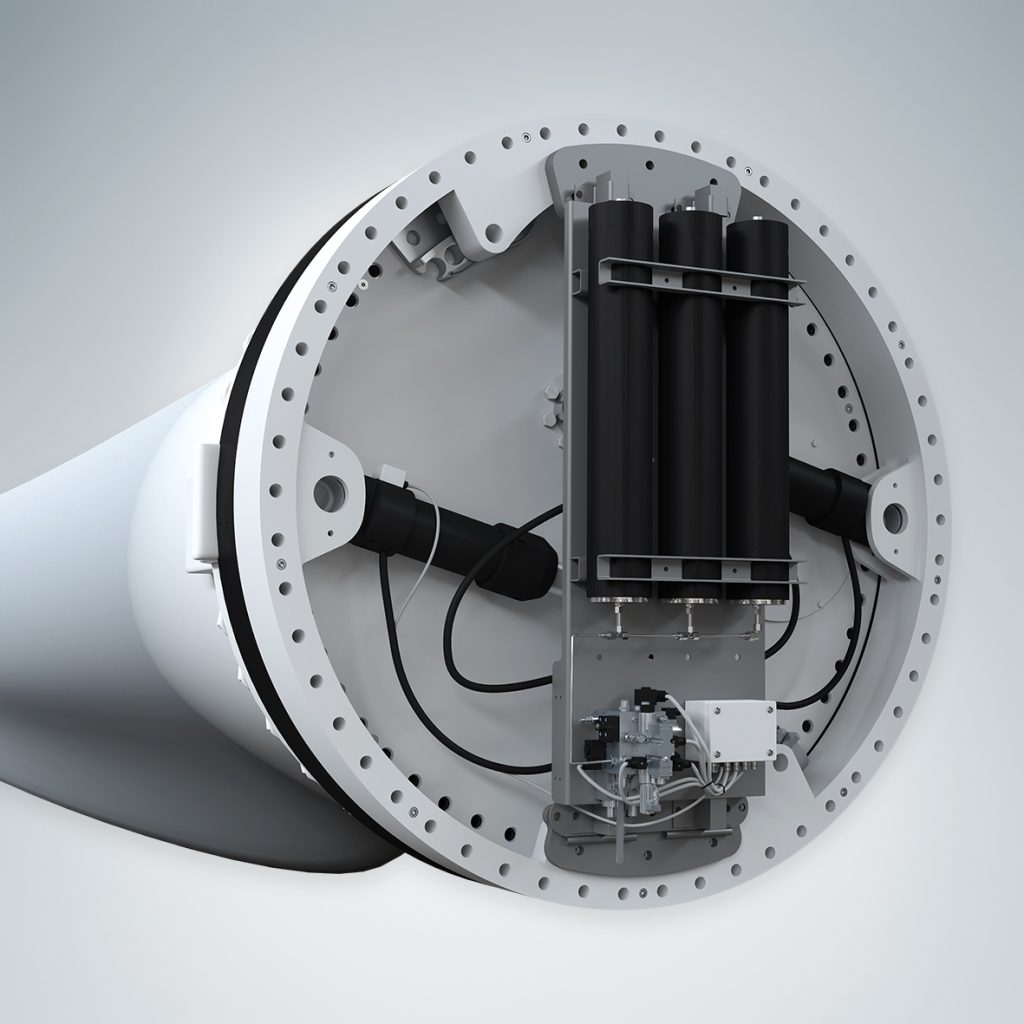

In electrification projects of mobile machines HAWE Hydraulik offers different concepts. The latest is the PowerBox, which offers enormous advantages for installation and in operation.

In addition to the battery packs, it also contains a new motor pump unit, a power distribution unit, a charger, and the hydraulics. The concept can be adapted to the specific requirements of the vehicle manufacturer, right down to the disassembled assembly, which can be integrated directly into the vehicle. Connected and fully charged, the PowerBox is ready for autonomous use and commissioning is accomplished in a very short time.

In addition, the included proven plug-in system for the battery packs significantly simplifies the management of the runtime of the electrically powered vehicle or the working hydraulics. When the battery pack charge is exhausted, it can simply be pulled out and replaced with charged spare batteries. This can be done in minutes, thus avoiding downtime. In addition, the battery packs can be charged flexibly at convenient times in the company’s own plant or on site. The solution shown is already being used successfully in loading cranes and can be used in the same way in aerial work platforms or even construction machinery.

For more information, visit www.hawe.com/en-us/.