How to Determine Hydraulic Pump Condition Using Volumetric Efficiency

Hydraulic pumps convert mechanical energy into hydraulic energy. A high-performance piston pump can make this conversion with an overall efficiency of 92%. If this pump drives a piston motor, then the motor can convert this hydraulic energy back into mechanical energy with an overall efficiency of 92%. The total, overall efficiency of this hydraulic drive, without considering losses in valves and conductors, is 85% (0.92 x 0.92 x 100 = 85).

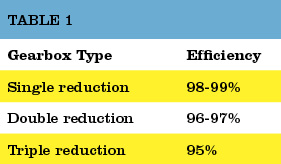

If this same drive transfer was accomplished with a gearbox, typical efficiency would be as illustrated in Table 1.

The inefficiencies or losses in a hydraulic drive can be divided into two categories: hydraulic-mechanical, which comprises flow and mechanical friction losses, and volumetric, which comprises leakage and compressibility losses.

The advantages of a hydraulic drive include high-power density (high-power output per unit mass), infinitely variable speed control, simple overload protection, and the availability of both rotary and linear motion from a single system. But as Table 1 shows, a key disadvantage of a hydraulic drive is that it is far less efficient than a mechanical drive. Plus, the wear process decreases a hydraulic drive’s volumetric efficiency (and therefore overall efficiency), causing the drive to slow down and more energy to be given up to heat.

The advantages of a hydraulic drive include high-power density (high-power output per unit mass), infinitely variable speed control, simple overload protection, and the availability of both rotary and linear motion from a single system. But as Table 1 shows, a key disadvantage of a hydraulic drive is that it is far less efficient than a mechanical drive. Plus, the wear process decreases a hydraulic drive’s volumetric efficiency (and therefore overall efficiency), causing the drive to slow down and more energy to be given up to heat.

The hydraulic pump is usually the hardest working component of a hydraulic system. As the pump wears in service, internal leakage increases and therefore the percentage of output flow available to do useful work (volumetric efficiency) decreases. If volumetric efficiency falls below a level considered acceptable for the application, the pump will need to be changed out. In a condition-based maintenance environment, the decision to change-out the pump is usually based on remaining bearing life or deterioration in volumetric efficiency, whichever occurs first.

Put simply, volumetric efficiency is the percentage of theoretical pump flow available to do useful work. In other words, it’s a measure of a hydraulic pump’s volumetric losses through internal leakage and fluid compression. It is calculated by dividing the pump’s actual output in liters or gallons per minute by its theoretical output, expressed as a percentage. Actual output flow is determined using a flowmeter to load the pump and measure its flow rate.

Because internal leakage increases as operating pressure increases and fluid viscosity decreases, these variables should be stated when stating volumetric efficiency. For example, a hydraulic pump with a theoretical output of 100 L/min and an actual output of 94 L/min at 350 bar and 40 centistokes is said to have a volumetric efficiency of 94% at 350 bar and 40 centistokes. In practice, fluid viscosity is established by noting the oil temperature at which actual pump output flow is measured and reading the viscosity off the temperature/viscosity graph for the grade of oil in the hydraulic system.

When calculating the volumetric efficiency of a variable displacement pump, internal leakage must be expressed as a constant. This is best illustrated with an example. I was recently asked to give a second opinion on the condition of a large, variable displacement pump. My client had been advised that its volumetric efficiency was down to 80% and based on this advice, he was considering having the pump overhauled.

The hydraulic pump in question had a theoretical output of 1,000 L/min at full displacement and maximum RPM. Its actual output was 920 L/min at 300 bar and 25 centistokes. When I advised my client that the pump’s volumetric efficiency was in fact 92%, he was alarmed by the conflicting assessments. To try to explain the disparity, I asked to see the first technician’s test report.

After reviewing this test report, I realized that the results actually concurred with mine, but had been interpreted incorrectly. The test had been conducted to the same operating pressure and at a fluid temperature within one degree of my own test, but at reduced displacement. The technician had limited the pump’s displacement to give an output of 400 L/min (presumably the maximum capacity of his flow-tester) at maximum RPM and no load. At 300 bar the recorded output was 320 L/min. From these results, volumetric efficiency had been calculated to be 80% (320/400 x 100 = 80).

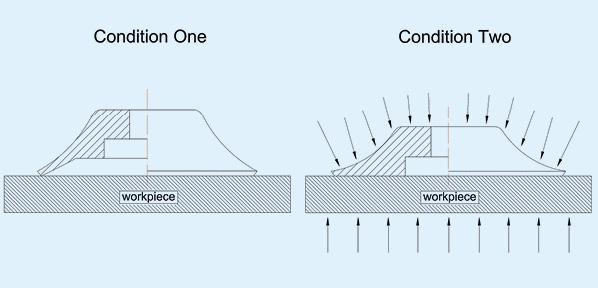

To help understand why this interpretation is incorrect, think of the various leakage paths within a hydraulic pump as fixed orifices. The rate of flow through an orifice is dependant on the diameter (and shape) of the orifice, the pressure drop across it, and fluid viscosity. This means that if these variables remain constant, the rate of internal leakage remains constant, independent of the pump’s displacement.

Note that in the above example, the amount of internal leakage in both tests was 80 liters per minute. If the same test were conducted with pump displacement set to 100 liters per minute at no load, pump output would be 20 liters per minute at 300 bar–all other things equal. This means that this variable pump has a volumetric efficiency of 20% at 10% displacement, 80% at 40% displacement, and 92% at 100% displacement. As you can see, if actual pump output is measured at less than full displacement (or maximum rpm), an adjustment needs to be made when calculating volumetric efficiency.

Of course, in considering whether it’s necessary to have the pump in the above example overhauled, the important number is volumetric efficiency at 100% displacement. And this was within acceptable limits. If my client had based their decision on volumetric efficiency at 40% displacement, they would have paid thousands of dollars for an unnecessary rebuild.

About the Author: Brendan Casey is the founder of HydraulicSupermarket.com and the author of Insider Secrets to Hydraulics, Preventing Hydraulic Failures, Hydraulics Made Easy and Advanced Hydraulic Control. A fluid power specialist with an MBA, he has more than 20 years experience in the design, maintenance and repair of mobile and industrial hydraulic equipment. Visit his website www.HydraulicSupermarket.com.