Identify Hose Assembly Terminal Ends and Determine Compatibility of Hose and Fittings

Consult SAE J517 and manufacturer’s guidelines to determine pressure ratings of the fittings, hose and their suitability for a specific application.

Hose Couplings

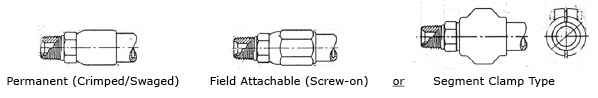

Care must be taken to determine proper compatibility between the hose and fitting. Hose from one manufacturer is not usually compatible with fittings from another. Do not intermix hose and fittings from two manufacturers without approval from both manufacturers. There are only two types of hose end fittings, permanent and field attachable.

Permanent fittings require crimping or swaging equipment to assemble to a hose. They are available in either pre-assembled or two-piece configuration. When using two-piece fittings it is important to match the ferrule with its appropriate stem and hose.

Field attachable fittings can be skive or no-skive, mandrel type and those that are stamped for DOT (Department of Transportation).

Caution:

Never mix fittings and hose from different manufacturers.

Never re-crimp or re-couple used hose with permanent or field attachable fittings.

Never reuse a damaged field attachable fitting.

Coupling Identification

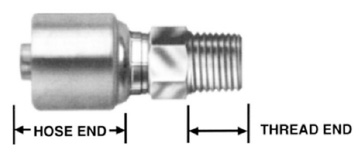

The hydraulic fitting consists of two functional ends.

The hose end is identified by the hose size and type to which it is attached. Serration patterns are specified by the hose manufacturer to meet hose performance. The thread end of a fitting can be identified by comparing it with the fitting being replaced or by measuring the port or thread end to which it will be attached.

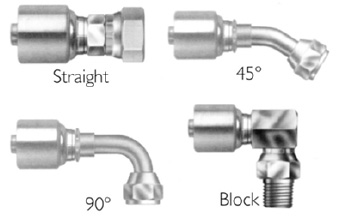

The variety of fitting configurations is quite large and in most cases fittings are selected based on the matching port or adapter connection and the routing requirements. Connection examples include Joint Industrial Council (JIC) 37°, Society of Automotive Engineers (SAE) 45° flare, or British Standard Pipe Taper (BSPT).

The image above shows a small sampling of the variety of fitting configurations. Selection will vary between the various applications, installations and hose types. Hose ends and thread ends are measured by industry standard dash sizes. The hose end dash size refers to the inside diameter in 1/16” segments (except for SAE 100R5 and SAE 100R14). The pneumatic industry uses the “inch” or “metric” sizing rather than the dash numbers.

Caution:

It is always important to measure the threads since there are so many threads similar in measurement and which may look very similar. The proliferation of threads on the world market today makes it easy to mismatch threads resulting in leakage and possible serious accident. Each manufacturer has its own shell and stem markings to match the different hose types. This marking system can be part numbers stamped on the product, notches, lines, etc. For this reason it is recommended to consult the manufacturer if there is any question.

Test Your Skills

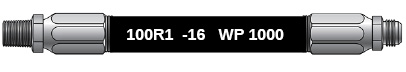

1. What four things are evident about this assembly?

a. 1” Male pipe to -16 37° male flare, 100R1 hose with MWP 1000.

b. Crimp-on hose fittings, 3/4” Male pipe to -16 37° male flare, 1000 MWP.

c. Field attachable end fittings, 100R1 hose, 1” I.D. and working pressure of 1000 psi.

d. Crimp-on hose fittings to 100R1 -16 with WP 1000.

e. Field attachable end fittings, 1” male pipe to 37° male and 100R1 hose.

2. To replace an assembly with field attachable fittings, it is important to:

a. Use new hose with the same fittings.

b. Never re-use field attachable if they have been damaged.

c. Use the same shell but replace the stem.

d. Use the same stem but replace the shell.

e. Use the same fittings if the shell is not damaged.

3. What distinguishes non-conductive hose?

a. Has MSHA imprinted on layline.

b. For hoses to be used in pneumatic service.

c. Hazardous effects such as explosions, fires and toxicity.

d. Has special imbedded wire in cover.

e. Has SAE 100R7 on layline and has orange cover.

What are the correct solutions?

Useful