Improving Assembly for Fluid Power Components

By Jim Kressler, Director – Facilities,

Bosch Rexroth Corporation

Manufacturing fluid power components such as valves and manifolds requires a lot of flexibility to accommodate different customer requests in an efficient manner. To help achieve this goal, Bosch Rexroth recently implemented a new Multi-Product Line (MPL) that combines automated and manual systems with Industry 4.0 (i4.0) technology that connects operators, machinery, and parts to make 34,500 different product variants. The result has been a significant increase in productivity, coupled with invaluable experience gained in the deployment of forward-thinking “Factory of the Future” technologies.

MANUFACTURING EXECUTION SYSTEM

The manufacturing execution system (MES) is centrally located in the plant and is responsible for collecting, filtering, and continually displaying production data. Since the MES is consistently running, it plays a crucial role in managing the MPL by providing operators and managers with immediate status updates from all areas of the line. The MPL uses the company’s ActiveCockpit technology to visualize production data from every corner of the plant on a single 65” screen. Employees can also access the information from mobile devices, laptops or tablets.

Since operators and managers can access the information from anywhere in the plant, ActiveCockpit can alert them of a problem, allowing them to take corrective action no matter where they are, reducing downtime and minimizing error. Employees use the ActiveCockpit to meet for 15 minutes at the beginning of every shift to review the previous day’s data and plan out the day accordingly. ActiveCockpit’s built-in functionality includes the ability to run meetings, including attendance, record and store meeting minutes, and send the notes to absent attendees. ActiveCockpit is also configurable for unique applications.

Employees use the ActiveCockpit to meet for 15 minutes at the beginning of every shift to review the previous day’s data and plan out the day accordingly.

RADIO FREQUENCY IDENTIFICATION TAGS

Industry 4.0 involves automated technology to support the worker in his or her everyday tasks. The key to effectively doing this is customization. Each worker on the MPL has a name tag with an embedded Radio Frequency Identification Tag (RFID). The individual workstations throughout the MPL are programmed to read the RFID tags and adapt the workplace to their skills and preferences. This includes ergonomic initiatives such as height-adjustable benches to providing instructions based on the worker’s level of experience. The RFID tag can connect with workstations to initiate material requests or assembly instructions on behalf of the worker, allowing employees to focus on creating high-quality products. Using RFID tags, the company ensures that each employee can work in a space designed specifically for his or her needs, increasing worker productivity and comfort. The same technology that customizes employee work processes also assists with identifying the product variants as they come down the line.

All products made on the MPL have a unique identification tag. As the products move down the line, the product’s RFID is closely monitored by the production control system to trigger replenishment of components when necessary. Additionally, product carts are identified by RFID tags and alert automatic guided vehicles (AGVs) to automatically pick up materials for the next production cycle.

LIGHT GUIDED SYSTEM

Once the workstation has identified the worker with the personalized RFID tag, the instructions for assembling the current product are beamed onto the station with a light guided system (LGS). Since the workstations are customized to the individual, the LGS displays the instruction with the level of detail appropriate for the worker’s level of experience. When executing an assembly task, the highest risk from a quality perspective is whether the right component makes it to the right spot at the right moment in the assembly operation.

To combat this challenge, the light guidance technology is equipped with a camera and sensors to confirm that operators move forward with the operation per the specification. If the camera detects that the operator is about to use the wrong piece in the wrong sequence, the LGS prohibits movement further in the instructions when it senses the inaccuracy. With its built-in scanners, the LGS has the ability to read the RFID tags of products, activating the instructions for that product to be displayed.

NEXEED PRODUCTION PERFORMANCE MANAGER

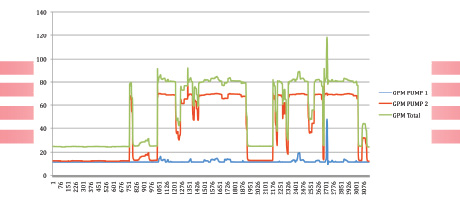

In contrast to the MES, which is mainly utilized for administrative documentation, the Nexeed Production Performance Manager (PPM), a software solution developed by Bosch Software Innovations, is installed in the MPL to monitor manufacturing processes. The PPM is designed to help users to visualize data in real time and has the capacity to track the many sensors integrated into the MPL, allowing it to measure features such as temperature, flow, pressure, vibrations, torque, sounds, and other operating characteristics. Like the MES, the PPM is customizable to a plant’s unique application.

With the PPM, users can apply pre-determined thresholds, or “rules,” to the data to ensure the plant is running efficiently. If a “rule” is crossed, the PPM can automatically issue a ticket and alert an appropriate employee with the right qualification and responsibility to deal with the affected machine for an immediate resolution. For example, if the PPM senses that hydraulic filters are clogged and the data shows performance levels below the threshold of a properly functioning filter, an alert is automatically issued to ensure quick action to address the problem. The ultimate goal is to get ahead of the maintenance process, minimize downtime, and ensure the equipment is always performing at its peak. In conjunction with a maintenance support system, the PPM can also provide diagnostics and recommend the ideal repair strategy from its knowledge database to maintain continuous operation.

The MPL mixes automated and manual systems with technology that connects operators, machinery, and parts to make 34,500 different product variants.

PRODUCTION IMPROVEMENTS

While using the MPL, the plant has experienced an impressive improvement in its production processes, with a 27% cycle-time reduction, 50% downtime-related maintenance, and a 50% reduction in floor space. More importantly, most of the Bosch Rexroth technology being utilized on the MPL is available for other companies that want to implement i4.0 in their own operations. The technology we added to our multi-product line is exactly what we needed to meet our objectives. Plus, we’ve gained invaluable firsthand experience with connected technology’s ability to enhance productivity and efficiency in assembly operations, parts supply, worker guidance, and quality control.