Improving Wind Turbine Reliability

The Importance of Reducing Stress and Improving Uptime in a Difficult-to-Maintain System

Given that maintenance for wind turbines involves the replacement of costly parts, as well as time-consuming and dangerous ascents of turbines up to 100-m tall, there is a constant focus within the industry on improving the reliability of these devices. Though it is impossible to predict all of the necessary maintenance in any device, taking a few steps while building turbines and during routine maintenance can reduce the risk of unscheduled downtime and the associated costs.

Given that maintenance for wind turbines involves the replacement of costly parts, as well as time-consuming and dangerous ascents of turbines up to 100-m tall, there is a constant focus within the industry on improving the reliability of these devices. Though it is impossible to predict all of the necessary maintenance in any device, taking a few steps while building turbines and during routine maintenance can reduce the risk of unscheduled downtime and the associated costs.

Wind Turbine Systems

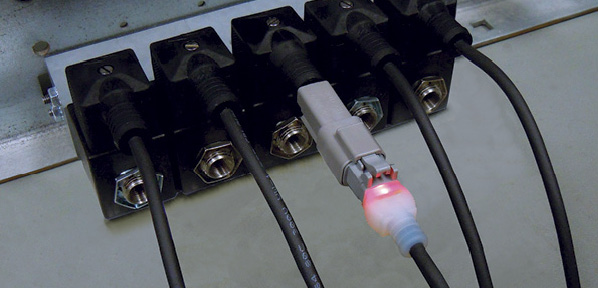

The system of power generation within a wind turbine is fairly simple. Wind turns the blades of a turbine, which in turn rotates a slow-moving crankshaft. The motion of this shaft is amplified by a gearbox before being applied to a rapidly spinning generator. The generator produces power, which is applied to the slip ring and is drawn off by carbon brushes in a brush holder mounted near the slip ring. The resulting power is taken to the grid.

Operating time is key to effective power generation by wind turbines. Since wind is not constant, turbine operators strive to keep turbines spinning for more than 98% of the time during adequate wind events. In order for this to be possible, all of the components of the turbine must be working properly. When the time, danger, and difficulty in replacing components—nearly all of which are concentrated at the very top of a turbine—is factored in, it becomes clear that long component service life is critical to effective power generation.

The carbon brushes resting on the slip ring are responsible for creating a brush film on the ring. Film conditions vary based on service conditions and brush grade. Excessively heavy films inhibit transfer of current, while films that are too thin lead to slip ring damage. An ideal brush film allows the slip ring to continue spinning smoothly without being damaged by the brushes while still effectively transferring power into the grid.

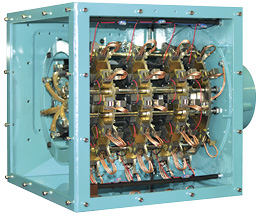

Choosing a Reliable Gearbox

Gearboxes are the components that fail most often within wind turbine power generation systems, so choosing a reliable, appropriate gearbox is important in reducing downtime. Performing adequate scheduled maintenance on the box, such as ensuring proper lubrication for the environmental conditions of the turbine, is also a key step to improve reliability.

Gearboxes are the components that fail most often within wind turbine power generation systems, so choosing a reliable, appropriate gearbox is important in reducing downtime. Performing adequate scheduled maintenance on the box, such as ensuring proper lubrication for the environmental conditions of the turbine, is also a key step to improve reliability.

Wind turbines are often placed in some of the harshest conditions on the planet. Offshore wind farms, for example, must contend with the high salinity of sea air, while wind farms in desert conditions contend with the dry air containing abrasive sand, high temperatures, and low wind speeds. Proper maintenance is especially important in these cases, as harsh environmental conditions wear down turbine components much faster than laboratory service conditions might indicate, especially if not maintained properly.

Selecting the Correct Brush Grade

Carbon brushes are the least expensive component in a turbine system and one of the easiest to replace, however they must be replaced the most frequently. A suitable brush can last up to three years and help to extend the service life of other components, such as the slip ring. Unsuitable brushes can lead to drastically increased costs and unnecessary downtime. When an unsuitable grade of brush for the turbine’s operating conditions is used, or worn brushes are left unreplaced for too long, they can create additional wear on the slip ring, causing it to degrade or lose roundness and force early replacement.

Selecting the correct brush grade is, therefore, an important step in turbine upkeep. The brush grade required depends on the service conditions of each turbine. Monitoring environmental conditions, such as humidity, temperature, and salinity, and consulting with an expert can help turbine operators find the ideal brush grade for each turbine installation. This leads to extended brush life, as well as extended service life for slip rings and brush holders.

Ensuring Roundness

Another critical step to improve the reliability of wind turbines is checking the roundness of slip rings while they are in service. Non-round slip rings place additional stress on carbon brushes, wearing them out faster than in normal conditions and causing early failure. Slip rings that are not round can also cause carbon brushes to spark due to a poor electrical connection. If this is the case, power is not being drawn from the slip ring as efficiently as possible, and overall power generation decreases.

With this information, wind turbine operators can reduce the overall maintenance necessary for their turbines, and therefore reduce downtime, time-consuming trips up and down turbines, and the danger to workers associated with these trips. In addition, the selection of appropriate components, such as carbon brushes and scheduled roundness checks with a profiler, can reduce the costs associated with turbine upkeep. Increased power generation uptime and reduced cost lead to the most cost-effective wind turbine operation possible.