How to Keep Oil Dry and Clean in Challenging Environments

For several dozen years, subsea hydraulic systems have relied on air springs to serve as self-contained volume compensators. Now the same technology that engineers rely on in drilling operations hundreds of feet below the sea is being used to keep oil clean and dry in challenging environments on land.

Dust, dirt, and moisture will all degrade hydraulic oil, which will cause reduced efficiency, and eventually damage, to hydraulic pumps, motors, valves, and other components. Keeping oil clean and dry is a first step in maintaining an operation and reducing long-term expense.

Many businesses are now using self-contained systems in environments such as saw mills and construction sites because they keep oil clean and dry much more effectively than breather cap filter systems.

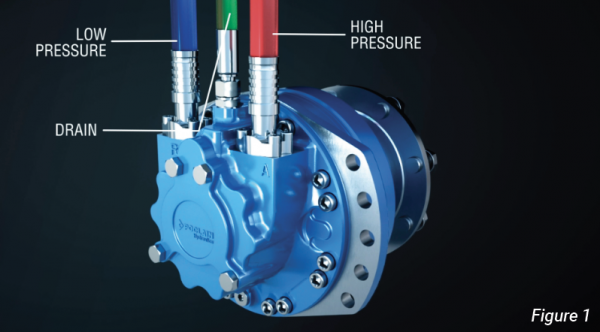

Subsea volume compensators are basically flexible-walled reservoir tanks that are used to allow the oil levels to change without creating vacuum or pressure. Most of these units have been on remote operating vehicles (ROVs) used for servicing underwater cables or drilling operations. The original applications for Firestone air springs as compensators date back to the days of the original deep-diving manned submarines for oceanographic research.

These systems expand or contact as the oil level goes up or down during actuation processes in hydraulic systems. It would not be possible under the sea for a traditional hydraulic breather system on an underwater reservoir tank to allow for this volume change. There is no air, and you don’t want to mix seawater with your oil.

Breather cap systems rely on filters—one on the reservoir tank to clean the air going in, and intake filters that are used between the tank and pump in the hydraulic systems themselves. However, clogged or dirty filters can cause flow restrictions that lead to pump cavitations.

With a self-contained system, you don’t need any filters. The oil is kept in a flexible-walled reservoir, and the tank expands or contracts as the oil level changes. In marine applications where moisture can contaminate oil and cause a reduction of lubricity, the sea air is not given a chance to touch the oil. It’s the same situation in a sawmill; you don’t need a breather filter, which would get clogged frequently, causing negative pressure in the reservoir.

We’ve found that Firestone air springs are highly effective as a pneumatic actuator in moist and dirty environments. They are used to provide force, move, lift, or press in saw mill, paper mill, construction, and agricultural applications. The longevity and durability of the products are proven in the very harsh environments that often lead to the most difficult conditions for hydraulic oil.

Reinforce your industry expertise with a Pneumatic Mechanic, Technician, or Specialist certification. Apply online at www.ifps.org.