KOBOLD’s MIM Electromagnetic Flowmeters Boast Space-Saving Design

KOBOLD’s new MIM provide extensive options for on-site programming. They are suitable for a wide variety of applications, particularly for batching. Configurable optical buttons can be used to display parameters such as flow rates or temperatures. A changing color system in the display also provides warning for limit violations. Since the MIM is the first to be produced in a remote version, the flow meter can also be used for media temperatures from -40°F to 284°F (-40°C to 140°C).

KOBOLD’s new MIM provide extensive options for on-site programming. They are suitable for a wide variety of applications, particularly for batching. Configurable optical buttons can be used to display parameters such as flow rates or temperatures. A changing color system in the display also provides warning for limit violations. Since the MIM is the first to be produced in a remote version, the flow meter can also be used for media temperatures from -40°F to 284°F (-40°C to 140°C).

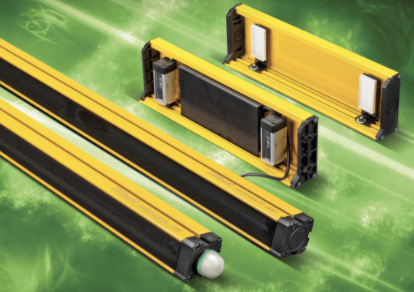

KOBOLD developed the MIM incorporating an IO-Link to meet Industry 4.0 requirements. They are suitable for almost any measuring situation and guarantee high programming freedom in addition to good response times of sometimes less than 100 milliseconds. Numerous functions, such as temperature measurement or batching, are performed accurately. The MIM can be set in just a few steps in the program menu with the hot key buttons. The rugged and flexible design enables simple and easy installation, even in tight-fitting pipe systems.

The MIM is made of stainless steel. In addition to the temperature measurement function, the MIM can be used for very small nominal pipe sizes and covers an even larger measuring range, depending on the nominal size. The multidisplay can also rotate digitally in 90° increments, so that when changing location, no other model is required, and the display is independent of the position of the connections.

The response time has been improved to facilitate more precise batching. In addition, different subsets can be programmed via the menu in order not to have to navigate with each new setting. The display has also been extended to hotkeys. With this feature, the desired dose can be conveniently selected by optical buttons on the home screen. The batching process can be started and stopped via an external control input and the quantity can also be changed at any time.

To ensure that this possibility is also available for hot media and in extremely temperature-controlled environments such as cooling water circuits, KOBOLD offers, for the first time, a remote version. Unlike conventional devices, the media-contacting unit only contains the sensor. The entire electronics, the control and display, are housed separately and connected via a cable at a safe distance to the sensor unit on the pipe.

For more information, visit www.koboldusa.com.