Load Sensors: Types and Best Practices in Selection and Installation

Various load cell types are preferred, relative to the needs of the laboratory or operational environment. When you need to convert force into a measurable electrical output, the load cell or transducer is the best application. Strain gage load cells are accurate within 0.03 to 0.25%. Used for experimental stress analysis and electrical measurement of resistance to strain, these load cells are used in most industrial applications. When precision mechanical balances are required, and where intrinsic safety and optimal hygiene is essential, pneumatic-type load cells are a better fit. In cases where the operation is in a remote location, the most applicable load cell type is still the hydraulic load cell because a power supply is not needed.

Types of Load Cells

Miniature – Subminiature and miniature compression load cells are designed to perform in high-capacity loads with minimum available space. Heavy-duty 50.8-mm (2″) diameter compression load cells have a low profile, and the small size accommodates test benches, industrial weighing applications, and prototype structures. They should include a twist-lock connector and a cable connection. There are miniature load cells in metric configurations, ranging from 0 to 100 and 0 to 50,000 Newton range. Sought-after features such as stainless steel rugged construction, built-in load button, high-accuracy, and a 5-point NIST traceable calibration are included.

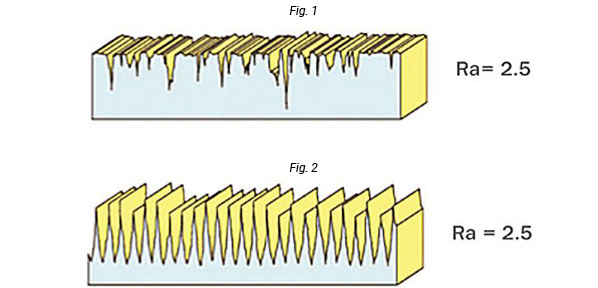

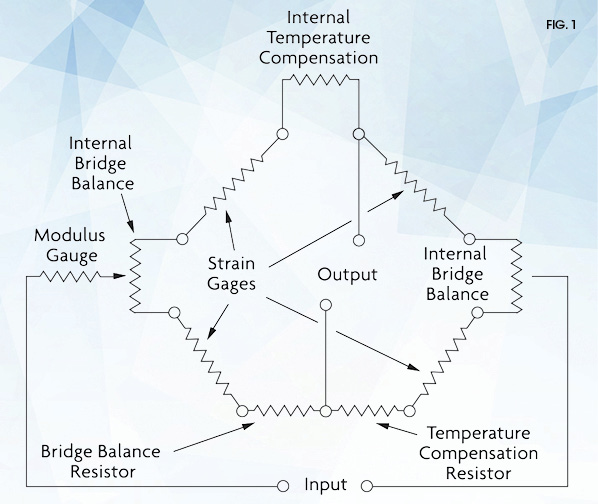

Strain – Strain load cell sensors are suitable for accurate dynamic and static measurement (Fig. 1). Designed with a grid of fine-grade wire or foil that is bonded to a carrier matrix backing, proportional variance of electrical resistance is in linear variance with grid strain. The strain is found by measuring change in resistance when force is applied to the carrier matrix, which is bonded to the surface. The carrier matrix and adhesive bond work together to transmit strain or change in resistance to the grid. Adhesive and carrier matrix also dissipates heat and insulates against electrical noise, which can act as interference and alter readings. The Wheatstone Bridge Circuit Theory is widely used in static strain measurement for its outstanding sensitivity.

Beam – Low-capacity bending beam load cells made of aluminum alloy have a capacity range from 1 to 500 kg. Used for OEM force measurement and weighing applications, industrial benefits include cost efficiency. Single-point load cells are also aluminum alloy with 1 to 500-kg capacity ranges. Heavy-duty shear beam load cells are manufactured in corrosion-resistant, nickel-plated, carbon-steel alloy. Shear beam and double beam load cells are also used in multiple cell applications like tank weighing and industrial process control. Cantilever or bending beam load cells are used for static weight, dynamic weighing, as well as force-measuring operations.

Platform – These hermetically sealed load cells are best for applications requiring water tightness and high accuracy, such as industrial food processing, weighing, and automatic weighing stations. Resistive load cells built with bonded foil strain gages can be accurate to ±0.02% of full scale, and they offer off-center load compensation, which is useful for building scales that are accurate, even when objects to be measured are placed anywhere on a loading platform.

S-Type – S-beam load cells receive compression output readings. They are designed to provide best performance in compact and versatile units, suspended loads, tank weighing, and hoppers.

Canister Style – This type of load cell is used for single and multi-weighing applications, also hermetically sealed and water resistant. The heavy-duty design canister load cell sensors are environmentally sealed to accommodate harsh environments and are best for axial compression applications.

Hydrostatically Compensated – The load cells are used for submerged operations like marine weighing, underwater platforms, in pit-flooding environments, and on dry docks. All stainless steel construction is very reliable in harsh underwater conditions.

Tension/Compression – Tension/compression load cells are versatile with low profile and welded stainless steel design. They are highly accurate in monitoring compression and tension forces. Industrial load cells with threaded load connections are constructed to measure tension or compression forces in harsh industrial environments. Bi-directional units range from 25 to 10,000 pounds in 2″ diameter (FSO Linearity of ±0.15%).

Industries that require load cell applications include power generation and alternative energies, cranes, hoists, and lifting technologies; military and defense industries; oil and gas exploration and production; aerospace and aircraft manufacture and technologies; and manufacturing and industrial automation. These industries require proven strain gage technology that can stand up to extreme temperatures, dust, dirt, and vibration. Load and pressure sensors must be resistant to various environmental extremes, waterproof, and rugged.

When selecting the type of capacitation load cells for integrative solutions for measurement of pressure, load, and force, industries require easy mounting options and rugged packages that offer high sensitivity that can be incorporated into specific applications. Many sensors can connect directly to a PC, which helps in writing software applications. Application requirements generally include capacity and size of load cell for the measurement of load or force.

Load Cell Selection

Measurement Duration: Short-term duration with a Tare, or longer measurement durations where Tare is not applicable

Output Requirements: Digital USB, wireless, digital RS232/RS485, analog mV/V, 0 to 5V, 4 to 20 mA

Measurement Speeds: 1 Hz, up to 100 Hz, faster than 100 Hz

Direction of Loading: Tension, compression, combination of both

Percent Accuracy Requirement: As a percentage of reading or percentage of full-scale output

Operating Temperature Conditions: Room temperature, outdoor temperature, well-controlled environment, harsh environment with wide-range temperature and humidity changes

Options for Mounting: Fastening sensor to both sides, unfastened mount

Certifications Requirement: Trade applications: NTEP or OIML certifications, testing or measurement ASTM E-74 or R&D certification

Operations Cost: Totals depend on small quantities or bulk volumes.

Best Practice Installation

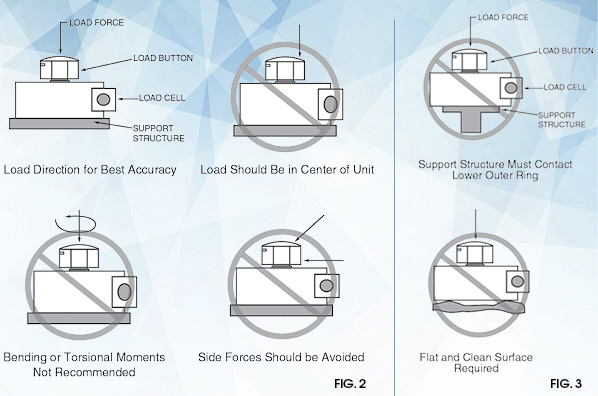

Each installation is unique; consult a structural engineer when in need of very high-accuracy, long-term stability, custom applications, and specifications, and when using varied R&D environments. In order to gain precise weighing results, be sure to use specified load applications for load cells (Fig. 2). Load cells have a specified load direction; do not apply side forces, bending, or torsional movements on load cells. Inappropriate loading applications will risk reducing the life of load cells, plus distortion of correct measurement results.

Using a rigid design for the support structure of load cells in compressive loading applications is preferred to pliable designs to achieve even lowering of all supports that also distributes tension and provides an even contact surface. Mounting the load cells to the support structure and rigid base plate ensures even load transfer from the base of the load cell to the support structure. This structure must also have the capacity to support the forces corresponding with the load.

Mounting aids may be needed for compliance with load cell installation. Seek assistance from the design engineer to determine the weighing of individual disturbance possibilities. Special considerations for weighing tanks, thermal expansions, monitoring levels, and horizontal movements for certain tank shapes and support structures are required to avoid measurement distortions. Your load cell support structure may need end-stops to limit lateral deflection, and elastomeric bearings can also regulate heat between the tank and load cell. Also, if your load cell requires self-centering, the design engineer may suggest a pendulum load cell that will automatically guide the super structure to its original position.

Specific Applications

Gas Turbine Engine/Rocket: These applications require high-accuracy measurements of the volumetric flow of gas through the pipeline. The turbine rotor turns the rotor blades by gas flow into the meter, measuring gas velocity. The rotor blades pass a pickup coil, generating an electrical signal pulse. The pulse is equal to a specific volume of gas. Total volumetric flow is recorded by the number of pulses. Expression of flow rate is measured in actual cubic feet or actual cubic meters (ACF/AM3).

Engine Thrust Measurement: This built-to-order combination torque and thrust reactionary and rotary load cell product is constructed in all stainless steel for long-term reliability. Applications in industrial environments include safe overload of 150% of capacity, ultimate overload at 300% of capacity. Call engineering for specifics.

Bin Weighing: To simplify load cell installations, use tank and bin weighing systems with capacities up to 2500 pounds. Systems provide shock absorption for industrial installations and help to prevent improper mounting, which can cause load cell damage. Make a complete four-point system with 4000-pound maximum capacity with heavy-duty shear beam-type load cells, and tank and bin weighing systems.

Process-Control Systems: The wide range of process controllers include temperature controllers, ramp and soak controllers, dual-zone controllers, and bench-top style process controllers. Microprocessor-based controllers come with various displays, wire RTDs, process voltage, and current. They can connect directly to the Ethernet network featuring an embedded web server, downloadable data-acquisition software.

High-Load Fatigue Testing: This testing reduces time needed for troubleshooting scale systems, analyzes conditions of strain gage-based load cells in scale and industrial applications. Tests load cells without disconnection, with easy-to-read, clear-screen messages. Provides essential data, like possible distortions from overloads, metals fatigue or shock loading, and possible ground faults or bridge resistance electrical problems.

Bridge Testing: Using a terminal block system with bridging and testing accessories across different clamping technologies reduces inventory and logistics costs. A modular terminal block design can be combined with different terminal block types or individually for application flexibility.

Considerations Before Install

Types of Installations: In addition to typical installations of hydraulic, pneumatic, and strain gage types of load cells, OMEGA customers often ask about bending beam load cells, shear beams, canister-type, ring and pancake load cells, and button and washer-type load cell installations. Some other more advanced types of load cell installations for specific uses include helical, fiber optic, and piezo-resistive.

Load Orientation: Service technicians find the most common cause of accuracy problems with load measurements is incorrect load cell mounting, which results in imprecise vertical loading that creates extraneous force errors. The loads must act precisely in the direction of the load cell.

Environment: Magnetic and electrical fields can sometimes create interference voltage within a measuring circuit. To ensure protection from EMC, place the load cell, connection cabling, and electronics in a shielded housing (Fig. 3). Do not ground the indicator, amplifier, and transducer more than once.

Framework Structure: Protect the measurement cable using steel conduits. Use shielded, low-capacity measurement cables, such as HBM cables. Avoid stray fields from motors, contact switches, and transformers. Using a rigid design for the support structure of load cells in compressive loading applications, preferred to pliable designs, achieves even/balanced lowering of all supports that also distribute tension and provide an even contact surface. Mounting load cells to the support structure and rigid base plate ensures even load transfer from the base of the load cell to the support structure. This structure must also have the capacity to support the forces corresponding with the load.

Today’s mechanical scales can weigh loads of all kinds, from pharmaceuticals to tanks and shipping cars. Consistency of weight calculations and readings require the best weight-balancing mechanism designs engineered to sense force, proper calibration, and maintenance. Depending on the output signals generated, we distinguish load cell designs according to weight detection, such as tension, compression, bending or shear, for example. Strain gage load cells convert on acting loads into electrical signals. The change in pressure of internal filling fluid measures weight by using force-balancing devices in hydraulic load cell designs. Higher accuracy requirements can be achieved using multiple dampener chambers, which also operate on the force balance concept with pneumatic load cell engineering.

For more information, visit OMEGA Engineering at www.omega.com.

© 2015 OMEGA Engineering, Inc. All rights reserved.