Looking Smart: New Pump Controller Nurtures Sustainability

By Marvin Schell, Development Engineer, and Dieter Lohmiller, Head of Construction & Development, Andreas Lupold Hydrotechnik.

In summer 2022, Andreas Lupold Hydrotechnik presented a new digital pump controller at the International Fluid Technology Colloquium in Aachen, Germany. It met with great interest from the expert audience. The benefits of the technology are that it optimally serves the trends of the industry in terms of sustainability, efficiency, complexity management, networking, and digitalization. The controller is the result of a group collaboration, including expertise from research.

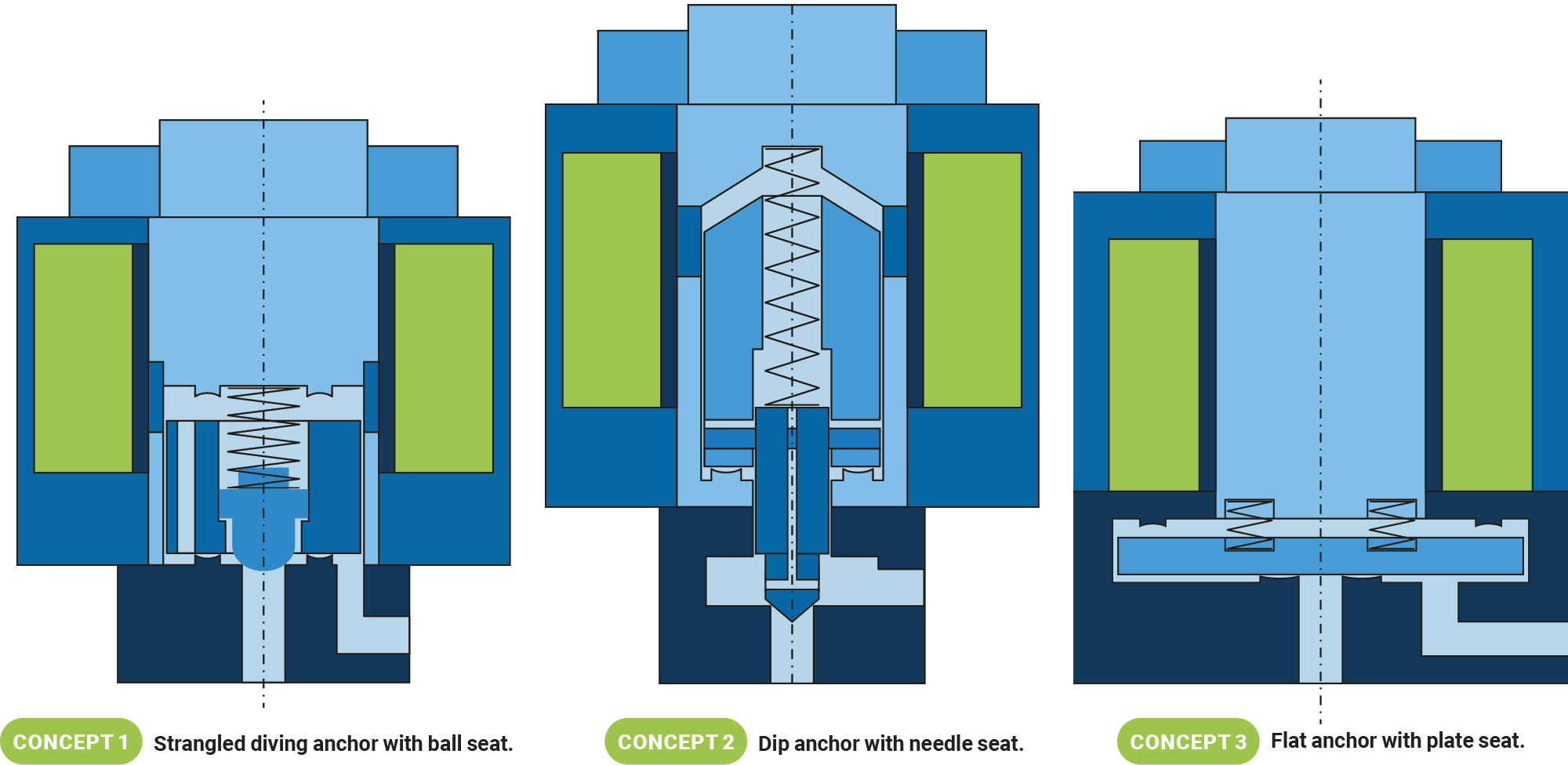

The pump controller was developed holistically. Contrary to what is often the case, it is not a further development of an existing solution. Lupold took a systemic approach, from the analysis of the optimal valve type to the development of the controller, with its two valves and its architecture, the coil and its control, and the software – everything was thought out and developed from scratch. The result confirms this approach.

Lupold developed the digital hydraulic controller holistically based on concept 1, as it combines the advantages of the compactness, switching speed, and damping of concepts 2 and 3.

Consumption, flexibility

Thanks to demand-optimized control technology and lower power loss, the energy consumption of the controller is reduced by up to 95%. The design with two independent and continuously controllable, leakage-free poppet valves enables the demand-optimized supply of the hydraulic oil. The inflow can be defined independently of the outflow of the pressure medium into the control chamber of the pump. Currently, it can be freely decided every 20 milliseconds how the valves should be actuated, how far they should open, and how long to hold the selected valve position. This is more than the typical digital 0 and 1. The controller opens the momentarily unique possibility of ideally controlling almost every operating point of the hydraulic pump. This means that the controller characteristics can be digitally adapted and adjusted to the customer’s individual needs via software parameterization during both commissioning and operation. As a result, the controller can take on every previously known function, as well as new ones in the future.

This type of control revolutionizes existing approaches to pump control. Via the controller, the pump becomes an active, smart system component that interacts with the machine control system and adapts its operating state to the respective requirement. In this way, much more flexible and efficient system architectures can be realized than with hydromechanical or previous electrohydraulic controllers.

The poppet valves also offer principle-based advantages such as freedom from leakage, enormous robustness and compactness, and a lower tendency to oscillate. The two-valve concept also makes it possible to compensate for faults in the hydraulic system – such as those caused by contamination and valve sticking – and eliminate them by means of pulsed flushing. In addition to the pump controller, it has been possible to develop a robust and economical proportional valve which, in contrast to slide valve-based solutions, is also suitable for functional safety applications.

Lupold’s digital hydraulic pulse controller.

Commissioning

The enormous potential for the user becomes apparent with regard to the implementation and realization of digital maintenance and calibration concepts. Thanks to digital control, the valve system is ideally equipped for digital condition monitoring, predictive or preventive maintenance, remote access, and automated commissioning.

Especially the latter is a big plus for manufacturers of hydraulic pumps in the production of their components. Functional testing and calibration can be carried out digitally. The adaptation of the pump to the desired pump controller variant is freely configurable via the controller software; the hardware remains the same. This not only speeds the testing process, it also reduces the complexity of component procurement because it requires only one controller, regardless of the application’s requirements.

Machine manufacturers benefit from the extended flexibility and the comfort functions in machine operation. Thanks to the possibility of connecting to digital fleet management and remote maintenance systems, the commissioning and setting of the controller – and thus the pump – can also be carried out remotely. Due to these prerequisites, the pump can be adapted to the ambient conditions and viscosity changes, for example, in the event of changing external factors in the field. On the system level, optimizations of the driving unit or powertrain can also result in additional efficiency benefits for the entire machine.

Remote monitoring of the pump is a major advantage for self-sufficient applications in areas that are difficult to access. Thanks to smart monitoring of the system, maintenance intervals can also be designed according to demand. This saves both personnel and energy resources.

The newly developed Lupold controller is optimized for the medium pressure range and is suitable for integration in new pump generations as well as for retrofitting on existing systems. The application and the technical solution are currently being patented. The programming interfaces and communication standards can be realized according to the requirements of the respective component or machine manufacturer. Certifications for functionally safe applications are also under consideration.