Maximizing Efficiency & Safety

Elements of this image furnished by Adobe Stock | Tricky Shark

The Role of Pressure Switches and Transducers in the Material Handling, Ski Lifts, and Snow Vehicles Industries for the Fall Season

By SUCO ESI North America, sucoesi.com

Material handling, ski lifts, and snow vehicles are preparing for an extremely busy fall season. It is important to ensure that all equipment runs smoothly and safely, especially with the unpredictable weather. Pressure switches are integral components of both hydraulic and pneumatic systems, and play a vital role in maintaining efficiency and reliability in these industries.

The Hydraulic and Pneumatic Pressure Switches provide a variety of applications in special vehicle systems like snow blower vehicles, snow terrain vehicles, tractors for snow, salters, telehandlers, skid steer snow pushers, and much more! We also provide high-quality pressure switches for mobile cranes, lifting platforms, scissor platforms, telescope platforms, hydraulic elevators, forklift trucks, conveying belts, and hydraulic winches.

What is the importance of pressure switches in material handling?

Forklifts, conveyors, and automated storage systems depend on having pressure carefully managed to operate smoothly and effectively. They require this precise pressure control because it directly influences their efficiency and performance. The reason these machines and systems utilize hydraulic and pneumatic systems extensively is due to the exceptional capability of these systems to deliver seamless and robust movement, essential for their tasks. The oversight and regulation of these hydraulic and pneumatic systems are facilitated by pressure switches, which play a crucial role in ensuring their proper functionality and safety.

Hydraulic systems in material handling

The high power-to-weight ratio of hydraulic systems and their ability to carry heavy loads make them the preferred choice for material handling. Hydraulic systems use pressure switches to monitor pressure levels. They then activate or deactivate a system according to preset thresholds. Over-pressurization can cause system failures and hazardous situations. Pressure switches are used in forklifts to ensure the hydraulic lift is operating within safe limits. This prevents accidents and damage to equipment.

Pneumatic systems in material handling

Material handling equipment is also commonly equipped with pneumatic systems. These are known for their reliable and clean operation. These systems also use pressure switches to ensure that the air pressure remains within safe operating limits. It is especially important for conveyor systems where constant pressure is required to move materials efficiently and smoothly. Pressure switches can help prevent scenarios where inadequate or excessive pressure may cause the system or the goods to damage or stall.

Enhancing safety in ski lifts with pressure switches

Pressure switches and pressure transducers are indispensable components for ski lifts, especially as the ski season draws near. As ski resorts gear up for increased visitor traffic, the safety and reliability of ski lifts become paramount concerns. Pressure switches play a pivotal role in safeguarding against potential accidents and ensuring the uninterrupted operation of ski resorts. By constantly monitoring pressure levels, these switches help detect any irregularities or fluctuations that could compromise the safety of passengers or disrupt the smooth functioning of the lifts. Thus, their presence is crucial not only for maintaining safety standards but also for enhancing the overall experience of skiers and visitors alike.

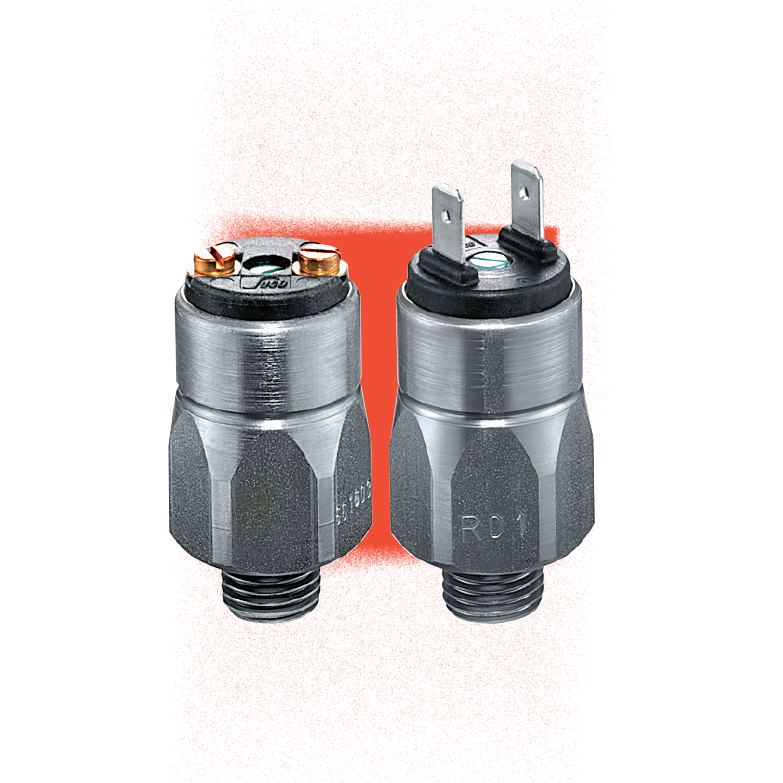

Photography courtesy of SUCO ESI North America.

Hydraulic Safety System in Ski Lifts

Hydraulic systems are used by ski lifts for a variety of functions. These include adjusting the tension in cables and operating the safety bar. These systems use pressure switches to maintain the optimal hydraulic pressure. This ensures that all components work correctly. Pressure switches, for example, can monitor the hydraulic system to ensure that the cables of the ski lift are correctly tensioned. This prevents sagging and snapping.

Pneumatic systems in Ski Lifts

In ski lifts, pneumatic systems are used to perform functions such as opening and closing safety bars or gates. Pressure switches and transducers are used to ensure these systems work reliably and maintain consistent air pressure for these crucial safety functions. These switches monitor the air pressure and can alert operators of potential problems before they become major ones, improving overall passenger safety.

Photography courtesy of SUCO ESI North America.

Pressure switches for optimizing snow vehicle performance

Snow vehicles, including snowmobiles and snow grooming machines, are essential for navigating the challenging terrain and harsh weather conditions of winter environments. Given the vital role these vehicles play in various activities such as transportation, rescue operations, and recreational pursuits, ensuring their reliability is paramount. Pressure switches serve as indispensable components in this regard, as they play a critical role in monitoring and regulating the hydraulic and pneumatic systems within these vehicles.

In the unforgiving winter weather, where temperatures plummet and snowstorms are common, the proper functioning of hydraulic and pneumatic systems is crucial for the optimal performance of snow vehicles. These systems power essential functions such as steering, braking, and lifting mechanisms, and any malfunction or failure could pose serious safety risks to operators and passengers.

Pressure switches act as vigilant guardians, continuously monitoring the pressure levels within the hydraulic and pneumatic systems of snow vehicles. They detect any deviations or abnormalities that may indicate potential issues or failures, allowing for timely intervention and preventive maintenance. By ensuring that these systems are operating correctly, pressure switches contribute significantly to enhancing the reliability and safety of snow vehicles, enabling them to withstand the rigors of winter conditions and perform their duties effectively.

Hydraulic systems in snow vehicles

Hydraulic systems are used to control the blades and tillers of snow grooming machines, which is crucial in maintaining ski slopes. Pressure switches are used to monitor hydraulic pressure. This ensures that the components work with precision, and prevents potential failures which could lead to uneven grooming.

Pneumatic systems in snow vehicles

In snow vehicles, pneumatic systems are used to control suspension and brake systems. Pressure switches maintain the correct pressure to ensure smooth operation, safety, and comfort. In snowmobiles for example, the pressure switches within the pneumatic suspension help maintain ride quality and stability, even on rough terrain.

Choose the Right Pressure Switches to Fit Your Needs

It is important to select the right pressure switches for hydraulic or pneumatic systems used in snow vehicles, ski lifts, and material handling. It is essential to use pressure switches of high quality that provide reliable performance and durability. Consider factors like the pressure range and operating environment when choosing pressure switches.

The Future of Pressure Switches for Seasonal Industries

As technology advances, pressure switches and pressure transducers are poised to undergo further evolution and enhancement. Innovations in sensor technology and digital signal processors are driving significant improvements in the accuracy and reliability of pressure switches. These advancements enable pressure switches to provide more precise and dependable monitoring of hydraulic and pneumatic systems, ensuring optimal performance even in the most demanding conditions.

By leveraging advanced sensor technology, pressure switches can detect subtle changes in pressure with greater sensitivity and responsiveness. This heightened level of sensitivity allows for more precise control and regulation of hydraulic and pneumatic systems, enhancing their efficiency and effectiveness. Additionally, the integration of digital signal processors enables pressure switches to process and analyze data more quickly and efficiently, facilitating faster response times and more proactive maintenance strategies.

The adoption of these advanced technologies is instrumental in advancing the safety and efficiency of hydraulic and pneumatic systems across various industries. By providing more accurate and reliable monitoring capabilities, modern pressure switches help prevent equipment failures, minimize downtime, and enhance overall operational efficiency. As such, they play a crucial role in driving continuous improvement and innovation in the realm of pressure control and system monitoring.

Photography courtesy of SUCO ESI North America.

Advanced Monitoring and Predictive Maintenance

Modern pressure switches and transducers have advanced monitoring capabilities. These devices provide real-time information on pressure levels. This allows operators to closely monitor the performance of their systems. These data can be used for predictive maintenance strategies to identify potential problems before they cause system failures. Predictive maintenance reduces downtime and extends equipment lifespan, resulting in significant cost savings.

Integrating IoT with Smart Systems

Another exciting development is the integration of pressure switches with the Internet of Things and smart systems. IoT-enabled pressure switches can communicate with the central control system, providing real-time alerts and updates. This connectivity allows more automated and responsive system management. It also improves overall operational efficiency.

Environmental Considerations

Demand for environmentally friendly solutions is increasing as industries become more eco-conscious. Increasingly, pressure switches that are environmentally friendly and energy-efficient are in demand. These devices reduce the environmental impact while maintaining high-performance standards.