New Festo Products Include Ultracompact Cylinders

Festo recently introduced a number of new products, including a line of shorter and lighter pneumatic cylinders.

Festo recently introduced a number of new products, including a line of shorter and lighter pneumatic cylinders.

ADN-S

Festo released ADN-S, a line of ultracompact pneumatic cylinders for smaller footprint, lighter, and higher performing machines.

Festo released ADN-S, a line of ultracompact pneumatic cylinders for smaller footprint, lighter, and higher performing machines.

Thanks to an innovative one-piece housing, ADN-S double-acting cylinders are 36% shorter and 20% lighter than similar actuators. Because their case material does not contain copper, zinc, or nickel as main constituents, ADN-S cylinders are recommended for use in production facilities manufacturing lithium-ion batteries. These cylinders are also recommended for electronic assembly and testing and are suitable for use in moderate-corrosion environments.

There are two ADN-S body types. The slim-design ADN-S requires only 6-10-mm installation space, while short-design cylinders fit in a 12-63-mm space. Units can be ordered with male or female thread piston rods for more flexibility in connection and with or without cushioning. The actuators feature a magnetic piston for position sensing and laser-etched case marking to make proximity sensor installation faster. Piston diameters range from 6 mm to 63 mm and stroke length from 5 mm to 50 mm, giving the line wide applicability.

For more information, visit Festo’s ADN-S page.

DHOP smart pipette

Festo has developed a closed loop smart pipette for automated, high-speed dispensing systems used in pharmaceutical, biotech, and cosmetic research and development.

To be released in mid-2022, the new DHOP smart pipette with DHAP low-force-tip family is designed for automated pipette applications where precision, validation, and process monitoring are needed. The DHOP’s three pressure sensors validate the performance of every dispense. Sensor data can be used to track dispense volumes and fluid characteristics. The pipettes can alert to clogged tips and sense liquid levels.

A key component of the Festo solution for dispensing systems is the Festo high speed EXCM gantry-robot. The EXCM family of gantry-based robots delivers +/- 50 μm precision positioning. EXCM gantries are available for workspaces as small as a sheet of paper to 1 m x 2 m and larger. The parallel kinematic H-gantry design offers low-mass/high-speed performance, as well as the largest possible deck area for the instrument’s footprint. The Festo VTOE 1- or 8-channel dispense head delivers precision high-speed dispensing in volumes from 1 μl to 1 ml and more with a total coefficient of variation in the 3% range for most applications.

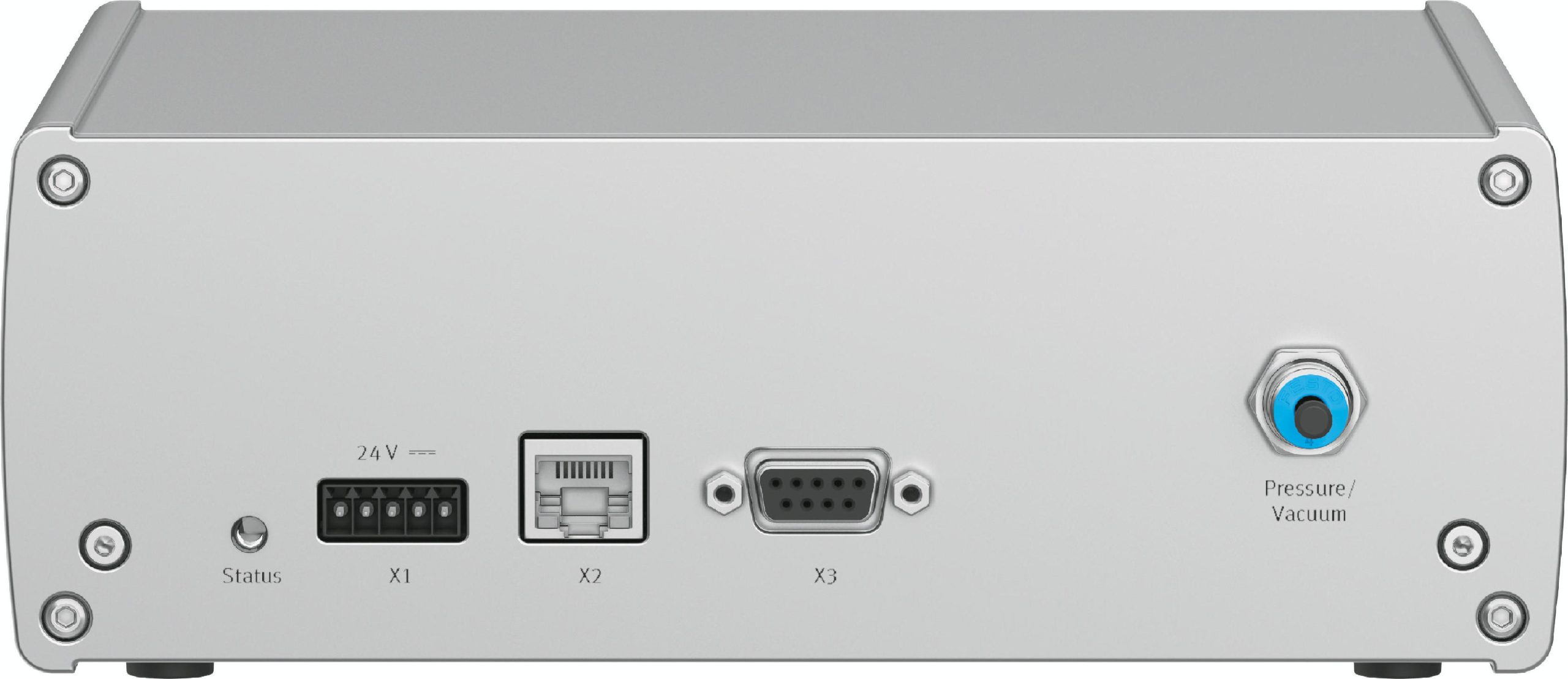

Combined with the award winning PGVA “airbox” pressure supply, a complete dispense system can be set up in minutes with a PC and controlled digitally or via Ethernet connection. The compact PGVA airbox, which measures only 8 x 3 x 8 inches, provides +/-700 mbar microfiltered air or vacuum with 10 mbar precision for a wide variety of laboratory applications. With a digital output for controlling solenoid dispense valves and pipettes, the PGVA supports a complete pipetting system.

Combined with the award winning PGVA “airbox” pressure supply, a complete dispense system can be set up in minutes with a PC and controlled digitally or via Ethernet connection. The compact PGVA airbox, which measures only 8 x 3 x 8 inches, provides +/-700 mbar microfiltered air or vacuum with 10 mbar precision for a wide variety of laboratory applications. With a digital output for controlling solenoid dispense valves and pipettes, the PGVA supports a complete pipetting system.

For more information, email customer.service.us@festo.com or visit www.festo.com.

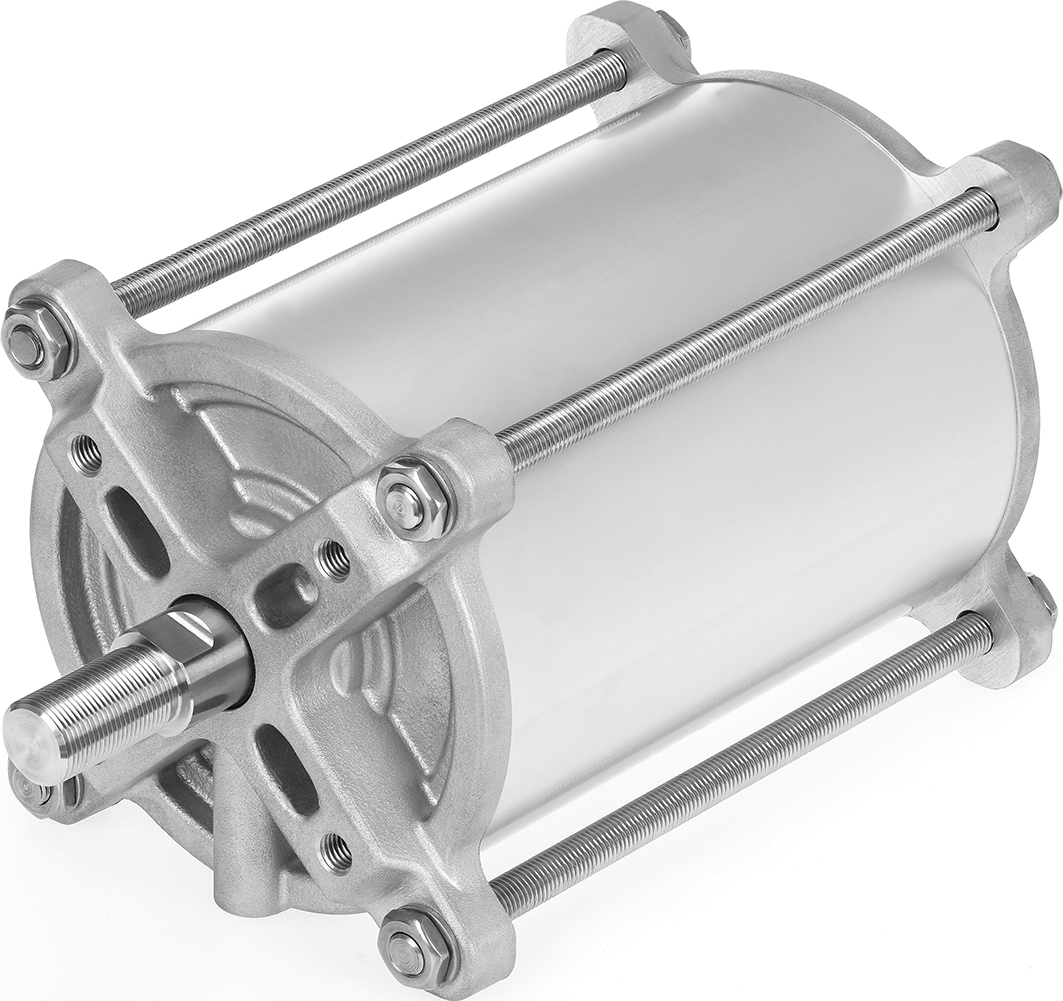

DFPC actuators

Festo’s new DFPC double-acting linear pneumatic actuators are optimized for process automation. The DFPC line gives OEMs and end users the ability to shorten design time, lower inventory, and simplify support through component standardization. Economical in-stock models reduce supply-chain risk, while customized models add design flexibility.

DFPC actuators are sturdy, corrosion resistant, and ideal for use in water treatment, mining, pulp and paper, power plants, and chemical and metals manufacture. Typical DFPC applications include actuation of gate valves, knife-gate valves, pinch valves, and process valves without housing. End-position cushioning on both sides enables greater performance through high-speed travel. Options for proximity sensors permit reliable end-position detection, while the optional external displacement encoder provides actual position.

Mounting based on the international standards of ISO 5210 and ISO 15552 simplify product substitution and create the opportunity for universal application. For long service life in harsh conditions, the DFPC piston rod, screws, nuts, and tie rods are made of stainless steel. The barrel and end caps are aluminum. Elastic cushioning rings reduce the piston impact force, which also contributes to long service life. Available piston diameters are 80, 100, and 125 mm; stroke lengths vary from 10 to 1,600 mm. Ambient operating temperature ranges from –20°C to 80°C (-4°F to 176°F). Operating pressure is 3 to 8 bar (43.5 to 116 psi).

For more information, visit Festo’s DFPC page.

PM aluminum tubing

Festo PM tubing uses standard push connectors (green center) and requires minimal space.

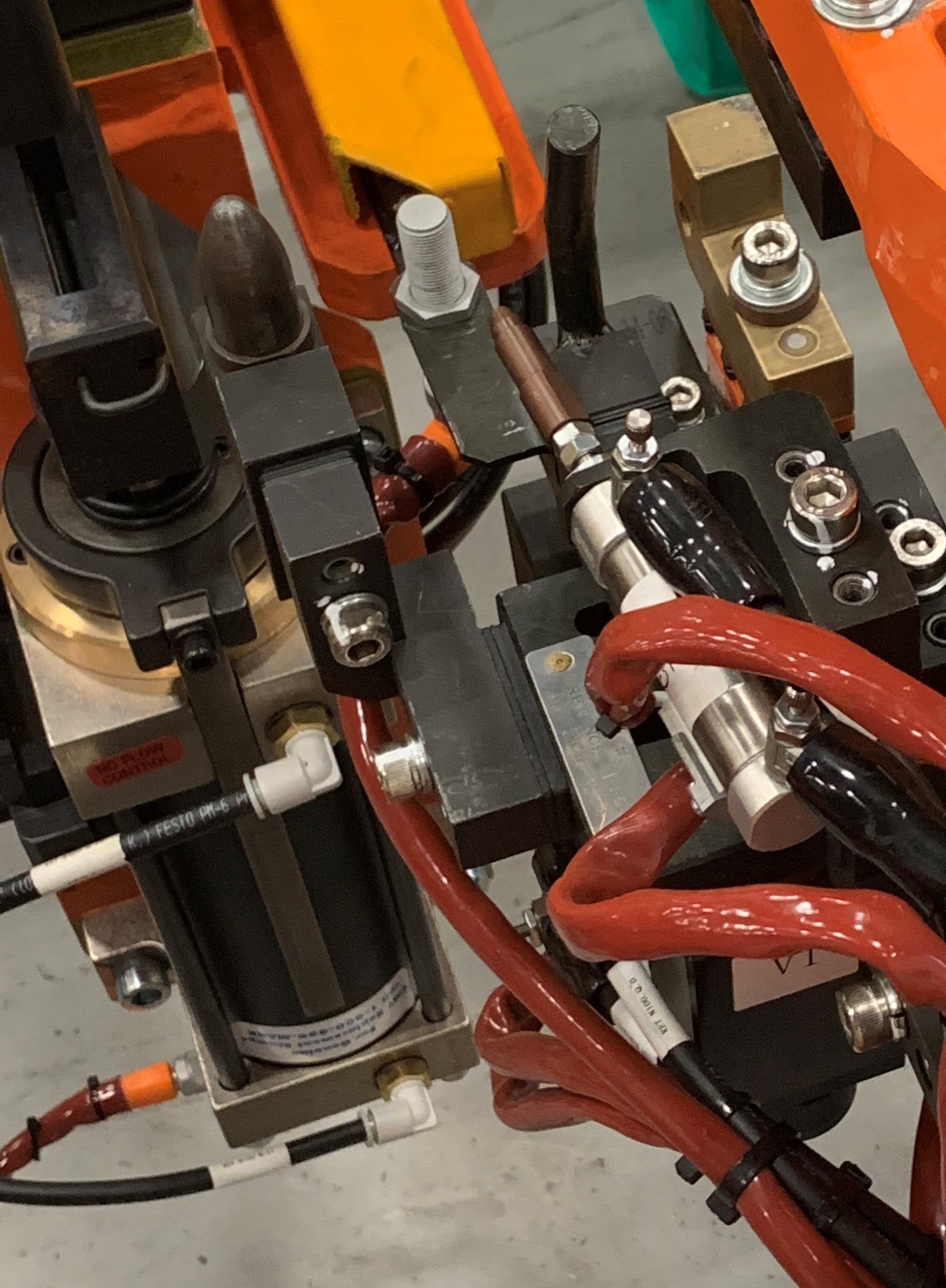

Festo’s PM aluminum pneumatic tubing offers a weld-spatter resistant solution in welding cells that by every consideration outperforms both laminated and steel pneumatic tubing. Festo PM tubing is ideal for new welding cells as well as for cost-and-time efficient retrofit solutions for existing systems.

PM aluminum tubing can be located closer to the welding process than laminated tubing, creating a more efficient pneumatic setup without the worry of burn through. There are no clearance issues with PM tubing as it has a nominal outside diameter, unlike some laminated options. PM tubing is designed for standard pneumatic push connectors right out of the box, while laminated tubing typically needs specialized tools or oversized connectors that require technicians to strip away the lamination to use standard connectors. Once formed, PM tubing holds its shape and stays in place without the need for additional clips and tie downs.

Heat and spatter resistant Festo PM tubing (black tubing lower left) is mounted close to the welding process (spot welding top left).

In comparison with steel tubing, the Festo aluminum solution is significantly less costly. Steel requires specialized tools to bend the tubing, but PM tubing is easily formed by hand to fit the contours of the welding system.

For more information, email customer.service.us@festo.com or visit www.festo.com.