Noisy Pump Causing Foam to Escape Through the Filler Breather

By Robert Sheaf, CFPAI/AJPP, CFPE, CFPS, CFPECS, CFPMT, CFPMIP, CFPMMH, CFPMIH, CFPMM, CFC Industrial Training

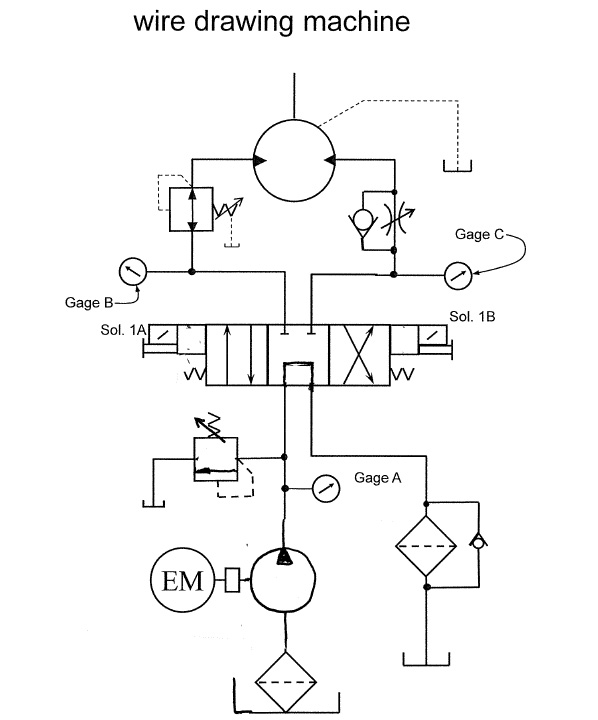

I was called to troubleshoot a foaming problem on a system that had the pump-motor unit mounted on top of the tank. When I got there, I was surprised that a root beer-like foam indeed was oozing from the filler breather cap and the pump was very noisy. Closer inspection showed that the foaming was worse when the pump was unloaded back to tank. I felt the pump noise was caused from the foaming problem, and the pump shaft seal showed a slight leaking problem when the unit was turned off.

Any idea what’s the cause of the problem?

See the Solution

The foaming problem oozing out of the filler breather was caused by the leaking shaft seal on the pump. When pumps are mounted on top of the reservoir, the suction line draws a vacuum with atmospheric pressure pushing the oil into the pump. However, vane and gear pumps route the case leakage back into the suction side of the pumps. Shaft seals are designed to keep oil in the pump housing and if there is a vacuum in the case, outside air can be drawn in, causing the foaming problem.

High inlet vacuum due to a clogged inlet strainer, pulling air in through the shaft seal of the pump. Worse when unloaded because there’s no case pressure to help the shaft seal.