Off-Road Diesel Mandate Exposes Need: Cleaner Fuel

By Aaron Keck and Rob Sabo, HYDAC

New diesel engines used in off-road equipment for construction, agriculture, and power generation must be “Tier 4” compliant by 2018 to meet Environmental Protection Agency (EPA) emissions standards that reduce the allowable levels of particulate matter and nitrogen oxides (NOx). The Tier 4 standards have been required since 2011 for diesel trucks and buses on U.S. and European highways. (Europe’s version of the standards is known as “Stage IV.”)

To meet the standards, new off-road equipment—excavators, farm tractors, heavy forklifts, airport ground service equipment, generators, pumps, compressors, etc.—is being equipped with a variety of emission control technologies, including exhaust after-treatment systems, electronic engine controls, and sensors. The changes have boosted performance and reduced emissions, but they’ve also increased the owners’ cost and associated expenses. What’s more, the fuel systems in these new engines are faced with significant design constraints as a result of three key changes in the diesel industry:

- the use of high-pressure common rail (HPCR) fuel injection systems

- the conversion to ultra-low sulfur diesel (ULSD), and

- the addition of biodiesel fuel blends to the stock diesel fuel.

HPCR Injection Systems

Diesel fuel injection systems are changing dramatically to provide cleaner combustion and meet Tier 4 requirements. Today’s fuel systems boast injection rail pressures of up to 43,500 pounds per square inch (psi) conditions compared with the 1,000 to 3,000-psi systems in mechanical fuel injectors from the 1990s. In addition, fuel system component tolerances are now as small as 1 micron—one-fortieth of what the eye can see.

With the new generation of high-performance, low-tolerance diesel fuel systems, the need for cleaner fuel has become increasingly apparent.

Equipment owners, operators, and fleet managers are experiencing more repair and downtime costs, thanks to poor fuel quality in Tier 4 engines. Many of these failures are the result of inadequate fuel filtration leading up to the point of injection.

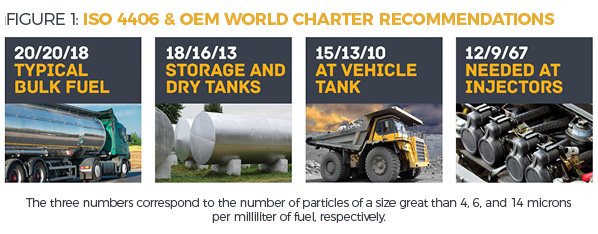

Numerous Tier 4 engines require a fuel cleanliness level of 11/8/6 at injection and 15/13/10 in the fuel tank. (The three numbers correspond to the number of particles of a size greater than 4, 6, and 14 microns per milliliter of fuel, respectively.)

According to the International Organization for Standardization (ISO) 4406, the Worldwide Fuel Charter standards at storage are 18/16/13, a dissolved water content less than 200 parts per million (ppm), and no free or emulsified water.

ULSD 15 and Biodiesel Blends

ULSD and the addition of biodiesel blends of B2 to B20 have added two more challenges to achieving the fuel cleanliness levels needed by today’s new engines and fuel storage systems. The removal of sulfur during refining also removes some of the natural lubricity compounds, so anti-water additives must be blended with the fuel.

Typically, ULSD 15 is hydrophilic with saturation levels between 25 and 100 ppm at room temperature. The addition of biodiesel causes these saturation points to rise dramatically: B2 up to 250 ppm; B5 to 500 ppm; and B20 to 1,600 ppm. As free water appears in the storage tanks, bacterial growth and premature degradation of the fuel storage systems can occur.

Until recently, filtration technology has not kept up. Absorption technology easily can be overwhelmed by all of the water and result in many more element change-outs than in the past.

This drives up filter costs, requires extra maintenance, and, in some cases, leads to lost business. When one retailer’s dispensers clog up, customers naturally turn to another retailer for their diesel.

Coalescing technology also has not improved, with cellulose still being the most commonly used media. Under current conditions, there are three major problems with this technology:

- The reduction of overall water-removal efficiencies compared with the past

- The water that can overwhelm the filters, saturate the cellulose, and destroy the media (think of wet cardboard) if not properly drained

- The formation of ice crystals on the media in low temperatures. This can cause additional cold-start issues, allow water to enter the injector systems, and foster microbial growth.

Today’s Outdated Filtration Strategies for Contamination Control

Typically, absorptive filters and coalescing filters applied at the point of dispensing have been used for contamination control. These are typically spin-on style filters providing filtration of particles down to 25-30 microns.

Alternatives for dirty or contaminated tanks include tank cleaning, polishing services, kidney loop systems, and microbial “spiking” agents (to kill bacteria). Although these systems can clean and polish the fuel, they usually do so with no particle count measurements, water tests, or ASTM 975 fuel testing. In most cases, the benchmark for success is simply how clean the fuel looks afterward.

These realities pose several problems.

First, in most cases, one cannot get to the required ISO levels in today’s fuel systems through a single-pass particulate and water-removal media at the point of dispensing. This is especially true if the bulk fuel delivered to the storage tank is contaminated or dirty. Bulk fuel from delivery trucks, trains, or barges is often between 25/23/21 and 21/19/17.

The use of cleanout services, polishing systems, and kidney loops for permanently installed systems can become costly and can consume a lot of energy. In addition, cleaning and polishing services are good only for the fuel in the tank at the time of service.

Also, when chemicals are used to treat and kill bacteria in a bulk system, the user is left with dead organisms and chemical byproducts. Both can have detrimental effects on fuel quality and the fuel injection system if allowed into the combustion chamber of an engine.

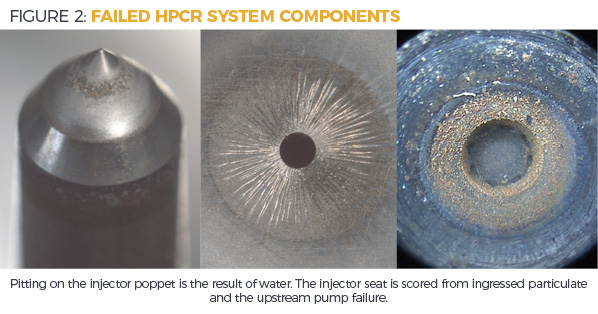

When HPCR pumps and injectors fail, most of these failures are attributable directly to solid particulates and water ingression. Fig. 2 is an example of failed HPCR system components. The pitting on the injector poppet is the result of water. The injector seat is scored from ingressed particulate and the upstream pump failure.

One catastrophic failure from a 4-liter to 6-liter HPCR system can cost more than $5,000. This does not include downtime costs and the inconvenience of the loss of equipment. Such a failure also may hamper construction schedules, contribute to the loss of backup power generation, or both.

The solutions mentioned can be especially effective if used in conjunction with a good, proactive maintenance plan. If water can be eliminated before it enters the system, most of the other problems may be mitigated with little effort. A small infrastructure investment upfront can be justified by the prevention of one to two HPCR failures in equipment.

Solutions, Impacts on Modern Systems

To achieve the lowest cost of ownership and meet fuel system requirements, protect a fuel storage and dispensing system at every point of transfer.

Start with a clean tank that is free of water and contaminates. After that, highly efficient single-pass filtration may be used at the points of transfer to protect from water and solids.

As Tier 4 engines infiltrate the market, the need for better filtration is becoming more apparent. Now, fuel filtration is being addressed from fuel production to the fuel injector.

From the time diesel fuel is produced, particulate filtration and water removal technologies are needed to ensure high-quality fuel to the end user.

As the first level of protection, high-flow coalescing filter vessels can remove particulates down to 3 microns with individual vessel flow rates of up to 951 gallons per minute (gpm).

At the point of bulk fuel delivery, the downstream fuel in storage should be held to an ISO cleanliness code of 18/16/13 and a water content under 200 ppm, according to the Worldwide Fuel Charter.

A number of bulk diesel filtration products are capable of flow rates ranging from 70 gpm to 280 gpm using fully synthetic particulate filtration and a water-removal efficiency of greater than 99.5% in a single pass. A filter skid can be applied as a fuel delivery filter or used as part of a high-flow filtration system to ensure cleaner fuel. A filter cart at 14 gpm or bulk diesel cart at 25 gpm and 70 gpm also may be used to clean contaminated fuel tanks to meet bulk fuel cleanliness recommendations.

Even with these efforts, the fuel in bulk tanks requires additional filtration to meet the cleanliness required by most original equipment manufacturers and injection system manufacturers. For dispensing applications, a fine filtration solution ensures clean fuel is being dispensed into the equipment.

To keep out new ingression of water and solids during filling and dispensing, one also must protect the ingression of air into a bulk tank system. Desiccant air breathers may be used to achieve this. In addition to dispensing filtration, each piece of Tier 4 equipment requires adequate pre-filtration to prevent fuel quality-related failures, premature engine filter replacements, or both.

This article was originally published in the Second Quarter 2016 issue of PEI Journal.

For more information: Aaron Keck is an applications engineer in fuel filtration and can be reached at aaron.keck@hydacusa.com.

Rob Sabo is group product manager for fuels and can be reached at rob.sabo@hydacusa.com. Visit www.hydacusa.com.