O+P Releases Unispeed USFL

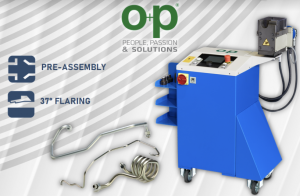

O+P recently introduced the Unispeed USFL 24/37 ES 6/18, specifically conceived to process process both flexible hose and rigid pipe bends when limited space that makes preassembling complicated.

O+P recently introduced the Unispeed USFL 24/37 ES 6/18, specifically conceived to process process both flexible hose and rigid pipe bends when limited space that makes preassembling complicated.

Thanks to its innovative layout, the machine allows users to easily preassemble DIN2353 rings and 37° JIC fittings on stainless and carbon steel tubes with Ø 6-18 mm (1/4-5/8 inches). In fact, the cylinder – its special rotating configuration is patent pending – has been separated from the main structure of the machine to allow for more working space. This, together with tools more compact than standard, allows users to comfortably preassemble tubes with a very short flat end.

The Unispeed USFL 24/37 ES 6/18 is particularly suitable to process rigid tubes with complex and narrow bends, such as shaped rigid tubes or composite tubes common in the automotive industry. The machine is equipped with an electronic control with touch-screen display, that allows users to save working recipes.

For more information, visit http://www.opusainc.com/.