Overheating Problem on a Sand Core Production Machine

By Robert Sheaf, CFPAI/AJPP, CFPE, CFPS, CFPECS, CFPMT, CFPMIP, CFPMMH, CFPMIH, CFPMM, CFC Industrial Training.

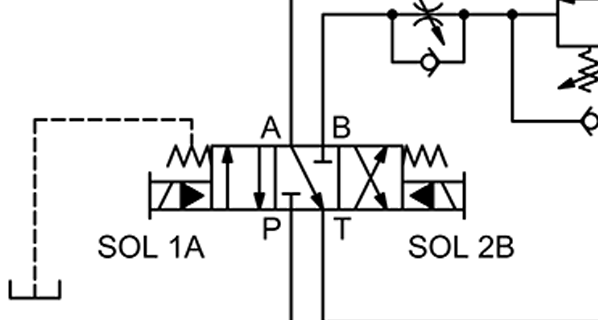

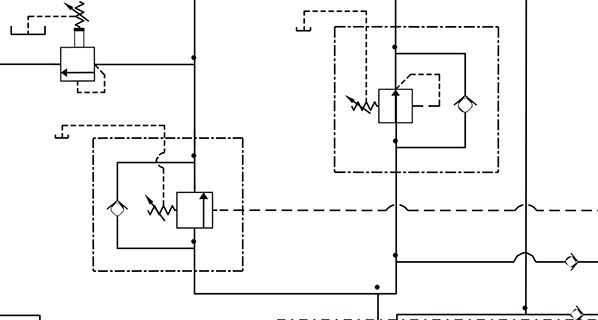

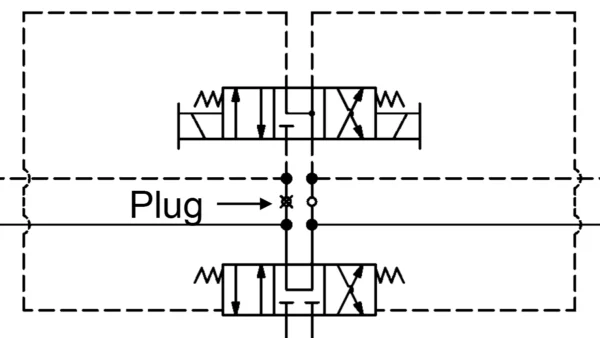

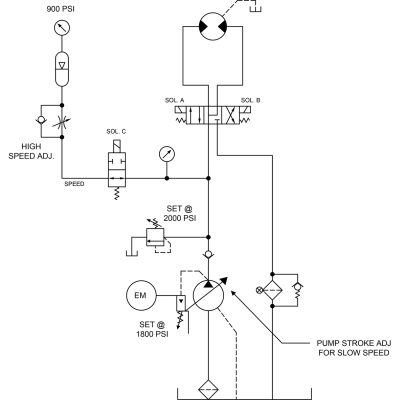

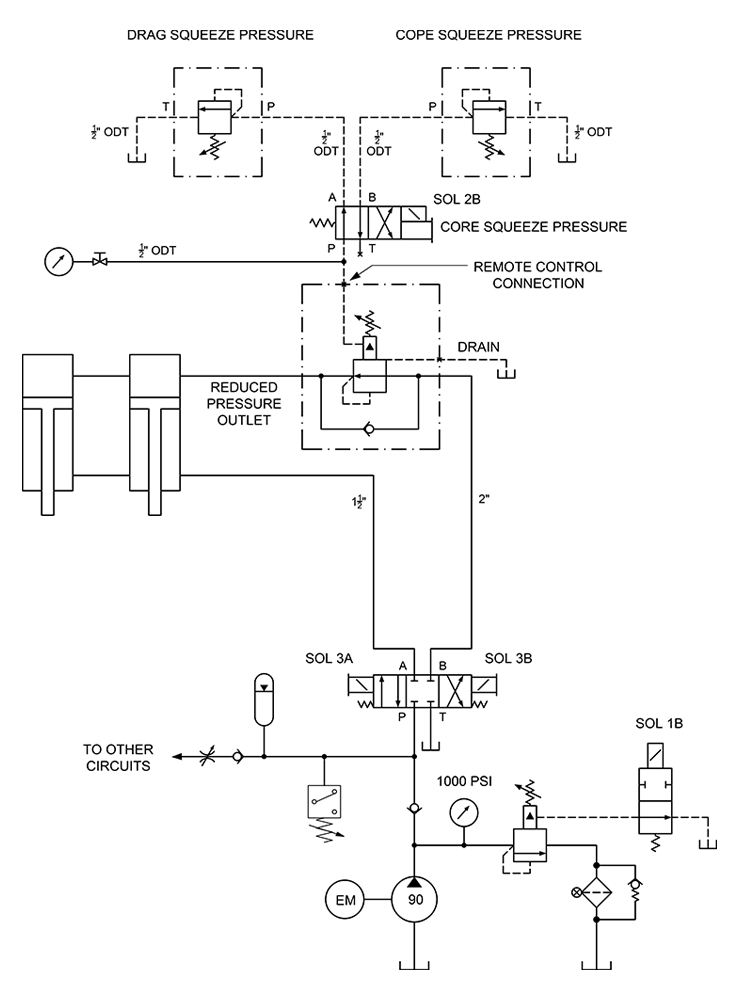

Back in 2016, I wrote up a problem on a machine that made sand cores. See the original circuit attached. Everything seemed to be the same other than they had omitted the other circuits that ran a couple small cylinders that were not used any more.

Lately, they started having overheating problems that needed to be corrected. The unit was located on a 300-gal reservoir, and they did not have this problem with overheating until they removed the 2-small cylinders that were plumbed after the check located near the accumulator.

Maintenance felt that the problem was with the main pump relief and solenoid valve #1 so they replaced both valves. This did not fix the problem. Unfortunately, they were not familiar with the Core Squeeze circuit thinking it could be the problem and asked for help.

See Solution

Robert Sheaf has more than 45 years troubleshooting, training, and consulting in the fluid power field. Email rjsheaf@cfc-solar.com or visit his website at www.cfcindustrialtraining.com. Visit fluidpowerjournal.com/figure-it-out to view previous problems.