Pump Continues To Fail After the Main Directional Valve Was Replaced Weeks Earlier

By Robert Sheaf, CFPAI/AJPP, CFPE, CFPS, CFPECS, CFPMT, CFPMIP, CFPMMH, CFPMIH, CFPMM, CFC Industrial Training.

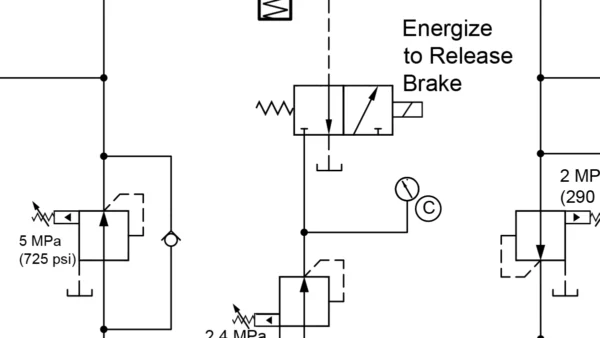

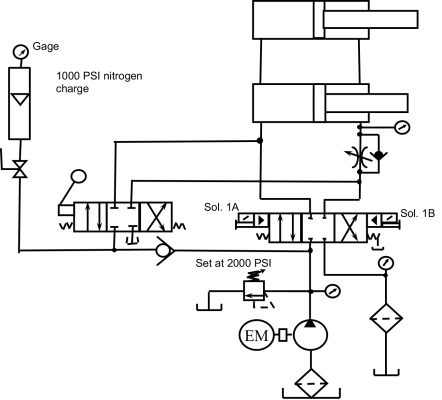

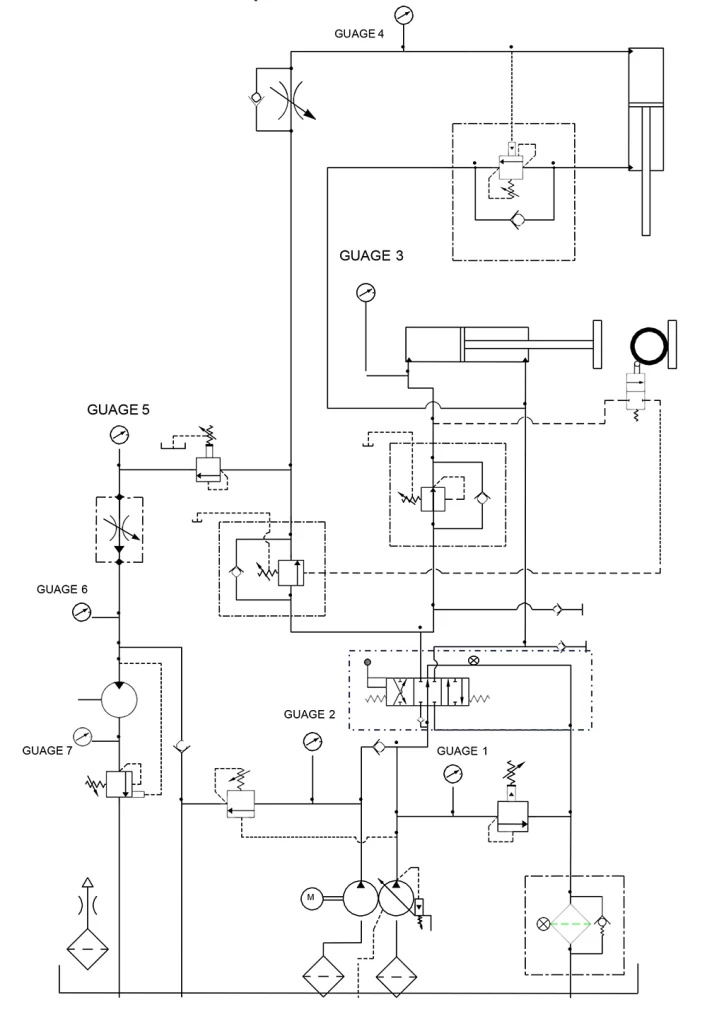

A manufacturer had a machine where the hydraulic system would clamp the part first, then extend a cylinder to stamp part numbers on its body. Then an air cylinder would extend a cylinder with a hydraulic motor attached to its rod that would grind a notch in the part. The operator would then reverse the air driven cylinder with the hydraulic motor as well as retract the two hydraulic cylinders and manually remove the casting.

A manufacturer had a machine where the hydraulic system would clamp the part first, then extend a cylinder to stamp part numbers on its body. Then an air cylinder would extend a cylinder with a hydraulic motor attached to its rod that would grind a notch in the part. The operator would then reverse the air driven cylinder with the hydraulic motor as well as retract the two hydraulic cylinders and manually remove the casting.

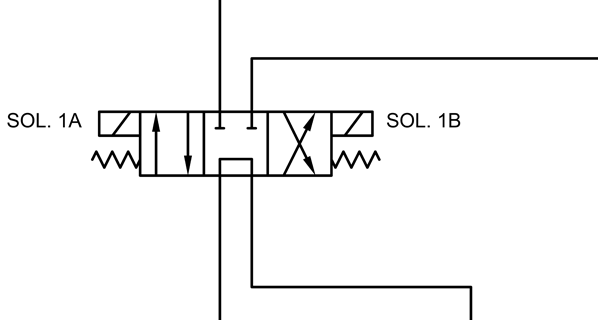

The manually actuated directional valve was worn out and replaced with a new one that was in their stores room. Several weeks later the piston pump failed, and they replaced it with a new one that only lasted less than 6 weeks. The pump manufacturer denied warranty claiming the cause was due to a lack of lubrication. How could this be when the pumps were located below the tank and the pump had a positive intake set-up?

See Solution

When the directional control valve was replaced with what they thought was the same set-up, had a plug missing. The valve was an open center and not a closed center set-up that was needed. This allowed the pressure compensated pump to unload close to zero PSI, greatly reducing the lubrication flow needed by these types of pumps. Lesson learned: Do not allow PC pumps to idle for any period length below 250 PSI that’s needed to keep these pumps from seizing.

Robert Sheaf has more than 45 years troubleshooting, training, and consulting in the fluid power field. Email rjsheaf@cfc-solar.com or visit his website at www.cfcindustrialtraining.com. Visit fluidpowerjournal.com/figure-it-out to view previous problems.