Pneumatic Assemblies Achieve Precision Pressure Control with High Flow Requirements

SPONSORED CONTENT

While products that combine high pressure requirements with high flows exist – like our QB3 and QB4 products – sometimes a standalone pressure regulator does not offer enough flow for a customer’s application.

While products that combine high pressure requirements with high flows exist – like our QB3 and QB4 products – sometimes a standalone pressure regulator does not offer enough flow for a customer’s application.

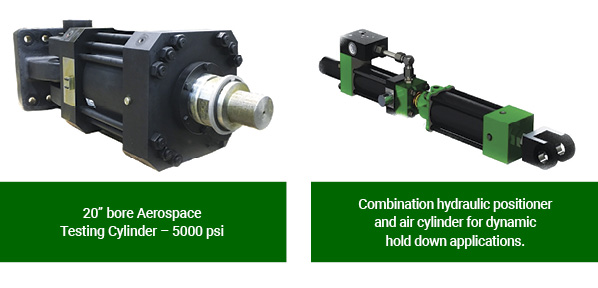

One solution to achieve the required flow while still getting precision pneumatic control is to pair an electronic pressure regulator with a volume booster, or an air-piloted regulator. This combination offers an increase in both forward and reverse flow while providing accurate pressure control.

Three distinct components often compose these assemblies – an electropneumatic pressure regulator, like our popular QB2; an air volume booster; and a pressure transducer. The electronic pressure regulator provides an air pilot signal to the dome of the air volume booster. The transducer measures output pressure of the volume booster and provides this feedback signal to the QB2. The QB2 adjusts dome pressure (based on this feedback) to achieve the commanded pressure in the process.

Nearly any combination of these parts can be assembled to meet a customer’s needs. Low pressure, high pressure, vacuum, process control and even assemblies for hazardous media can be configured.

Contact our Applications Team to learn more about custom solutions for precision pressure control when flow requirements are high.

McCordsville, Indiana

McCordsville, Indiana

877-406-3215 • info@proportionair.com

ProportionAir.com