Repairing Hydraulic Servo Valves in Seismic Vibrator Trucks

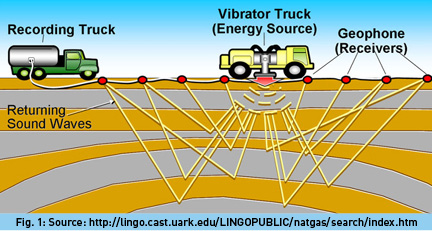

Seismic vibrator trucks (aka “thumper trucks”) send shockwaves deep into the earth’s subsurface to locate untapped hydrocarbon reserves for the oil and gas industry. These shock/soundwaves reflect back to the surface, where they are picked up and recorded by geophones. This seismic data is later imaged with advanced software (think: ultrasound) and analyzed by geologists who advise oil companies on where to drill for oil reserves (Fig. 1).

Not surprisingly, high-quality seismic data is mission critical. Geophysical surveys can cost $50,000 or more per square mile depending on the territory, and multi-million dollar projects—sometimes billion-dollar projects—are ultimately on the line. In short, there’s no tolerance or margin for error in this industry.

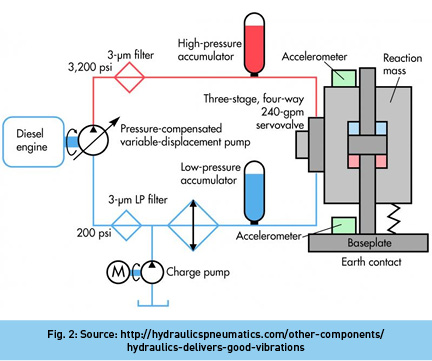

Thumper trucks are intricate machines, however, powered by complex hydraulic and mechanical systems. To generate the massive force necessary for a controlled and effective sound blast (for perspective, dynamite used to be the preferred method for this), all equipment must be highly precise and high performing (Fig. 2).

When the base plate of the vibrating truck rapidly “thumps” the ground, the vibration puts acute stress on the mechanics driving the action. Hydraulic servo valves are a key example of this. By porting fluid and directing the hydraulic actuator to vibrate the base plate, servo valves are especially important components that are susceptible to wear and malfunction.

High-intensity vibration exposes these high-performance valves, which are usually complex three-stage and four-way valves, to a variety of problems that can corrupt other parts and lead to failure and downtime. Although these issues are difficult to diagnose in the field, servo valve failure is most often caused by the following:

• Contamination: servo valves in vibrator trucks are exceptionally precise assemblies, and the smallest particles can cause them to fail.

• Internal part failure, especially

- torque motor failures

- spools wearing out

- AFSAs (a directional needle inside the servo valve) developing flat spots

Unfortunately, pinpointing the faulty servo valve component is only half the battle.

Regardless of whether or not the defective or broken part is identified, most geophysical exploration companies rely on the component’s OEM to restore equipment to working order. This dependence on OEMs is a costly and inefficient arrangement because it typically only provides customers with one option: replace your out-of-warranty defective parts with brand-new (expensive) parts.

PSI’s servo valve lab operations are set in a temperature-controlled, clean room environment. When a defective valve is shipped to the PSI facility and the staff determines the extent of the damage, the following repair steps are executed:

1. Test servo valves on run-in test stands.

- Check performance to OEM specifications.

- Determine repair requirements.

2. Analyze fluids running through the customer’s process.

- Recommend fluid improvements.

- Suggest maintenance requirements.

3. Disassemble valve.

4. Clean all parts ultrasonically in a heated vapor degreaser system.

5. Replace all broken, worn, and missing parts.

6. Reassemble the valves using new Viton seals.

7. Test valves on a dedicated test stand capable of low and high flow testing.

When the PSI repair process is complete, the remanufactured, like-new condition servo valve will always meet the same industry specifications for performance as new valves, and it will often exceed the expected lifetime of the original valve.