Research to Watch: Investigation of Noise Transmission through Pump Casing

This column will bring you the progress of the pre-competitive research being conducted at member universities that are part of the CCEFP network. This research will help give insight into the future direction of fluid power.

The Center for Compact and Efficient Fluid Power (CCEFP) holds a monthly forum, highlighting research, workforce, and special topic presentations.

CCEFP is a network of fluid-power-research laboratories, academic faculty, graduate and undergraduate students at nine universities. It is also a National Science Foundation Research Center. For more information on CCEFP, visit www.ccefp.org.

Since 2014, the National Fluid Power Association (NFPA) Foundation has supported and is helping to expand the pre-competitive fluid-power-research activities of the CCEFP, dramatically increasing the number of institutions and students impacted by its research program. For more on NFPA, visit www.nfpa.com/aboutnfpa/missionfocus.aspx.

Presented by: Paul Kalbfleisch, Researcher, Dan Ding, Researcher, and Monika Ivantysynova

Institution: Purdue University

PURPOSE

The goal of the investigation is to account for the large simulation errors and the lack of sufficient experimental validation in an attempt to incrementally validate noise modeling techniques and understand the noise generation by swash plate type axial piston machines. In the process of investigating, the researchers aimed to develop a more robust in situ methodology of experimentally diagnosing and modeling the oscillatory energy with a positive displacement machine.

PROGRESS

Resolving vibroacoustic problems involves impact testing that shows there to be high damping in regards to frequencies with high modal density. The higher the damping, the higher the forces of impact. Consequently, the higher the modal, the more accelerometers leading to dependent operational damping and full fluid film isolations.

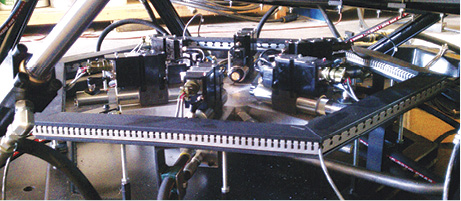

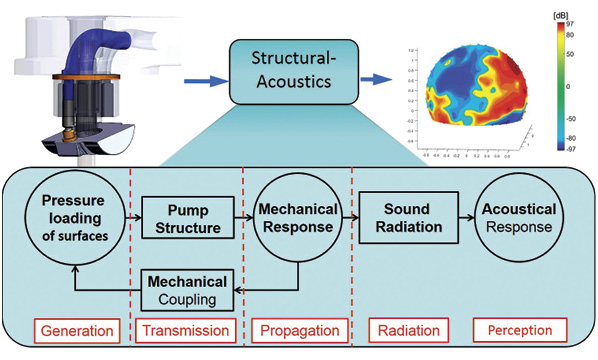

Therefore, the researchers examined the main frequencies of interest and what modeling method should be used. After reviewing which noise modeling technique was most important (analytical, numerical, energy-based or geometrical), the team, with omni-directional sensors such as microphones and pressure sensors, determined how to bridge the gap between noise generation and perception within structural acoustics. From generation to transmission to propagation to radiation, then finally perception, automated spatial sampling revealed that the in situ methodology was the most beneficial technique to measure the source of pump noise.

NEXT STEPS

With the final result supporting in situ experimental methodology, the analysis provided the team with a lot of information regarding the acoustic environment. While measuring more sound than any other experimentations in the past, the researchers discovered that the higher frequency sound is more broadband than other pump noise. This revelation was confirmed even in the presence of pump harmonics, 1-8 shaft order oscillations, and broadband transient spikes.

The research team saw a clear indication that in order to measure pump noise to access how to reduce the noise, in situ methodology is the preferred method measurement process. For future iterations, the in situ methodology will fill the void in experimentally diagnosing and modeling the noise emitted by positive displacement machines that utilize pump casings.