Rethinking The Venturi Tube

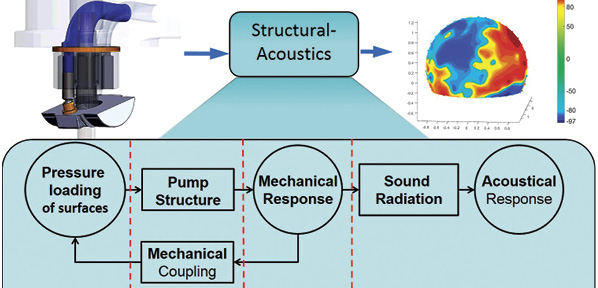

The differential pressure gauge is one of the most overlooked and forgotten measurement instruments in the industry. This is surprising because these devices have a tremendous variety of applications. They have the ability to monitor filter systems, display liquid levels, and even measure flow rates based on a difference in pressure. Measuring flow rates with these gauges is particularly interesting because they link the difference in pressure of a piping system to a square root relation of the flow rate in the system. This is all possible because of the Bernoulli Principle we learned in our fluid mechanics classes.

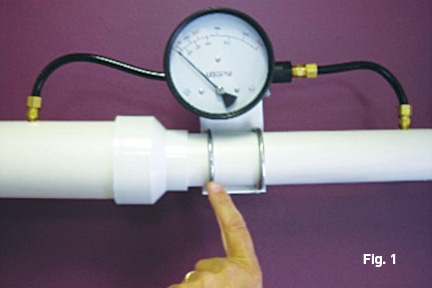

Engineers in the flow industry seek to find measurement devices that reduce energy losses and are simple to install and maintain. Differential pressure flowmeters, like the one in Fig. 1, meet these expectations extremely well, yet they remain underused by designers. Their accuracy averages to +/-1% of full scale, they result in far less energy loss when compared to other standards (such as the turbine or vortex instruments), and often cost under $500. Why would these devices remain so underused? Simply put, there is a common misconception that a designer must use a contraction in the piping to create a differential pressure. This is simply not true, and I am here to tell you an equally simple method of creating the required pressure drop.

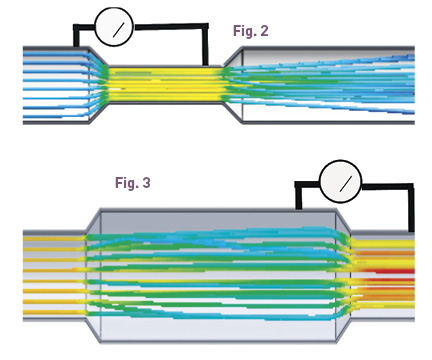

Contractions, such as the venturi tube shown in Fig. 2, can result in circular flow, turbulent vortices, and even present potential issues such as cavitation when used too closely to pumping systems. Fortunately, these issues can be greatly reduced if throttling is achieved in a less abrupt manner. If an effective design is achieved, laminar flow will be maintained and energy losses will be greatly reduced. Still, the industry maintains a distance from this type of flow measurement. To overcome this, designers of these systems must begin utilizing something more efficient than the contraction form of the venturi tube. They must begin to incorporate the expansion or “bulge” tube in their systems.

Creating an expansion in a piping system results in a pressure increase in the larger pipe thanks to Bernoulli’s Principle. This can be seen in Fig. 3 in which a piping system with the same inlet pipe diameter and flow rate as Fig. 2 is analyzed. The color of the flow lines in this system transfer from red to blue, signaling the velocity of the fluid is transferring from high to low. This is directly in accordance with our fundamental fluid mechanics knowledge and allows an engineer to utilize a differential pressure flowmeter with the application of the Bernoulli Principle. This expansion setup has equal accuracy to the contraction form of the venturi, yet results in fewer losses and creates a more uniform laminar flow through the transition between pipe diameters. This design also alleviates any possibilities of other venturi-related issues such as clogging from solids or negative pressures on the outlet end of the expansion.

What is most interesting about this concept is the fact that it has been completely neglected from any engineering program on fluid mechanics. As a result, the standard for these systems continues to be the contraction form of the venturi tube. If the designers of these systems utilize this new concept, they will be presented with systems that are incredibly simple to install and even easier to maintain. This results in lowered costs and ultimately improves the efficiency on all accounts.

About the Author: Matthew Schell is the vice president of engineering at Differential Pressure Plus Inc. (www.differentialpressure.com), a manufacturer of differential pressure gauges and switches. He holds a dual degree in Mechanical Engineering and Product Innovation from Virginia Commonwealth University.

Yes, but apart i the application mentioned here, what other application could be bult. regardsa

I stumbled upon this bulge or expansion venturi was quite impressed how could i use this for garden fertilizer the other venturi has a suction port .which can easly be clogged in the bulge . the bulge where is the suction i was thinkig the line coming off the bulge was the suctio line TY