Return Line Filter Leaking Problem

By Robert Sheaf, CFPAI/AJPP, CFPE, CFPS, CFPECS, CFPMT, CFPMIP, CFPMMH, CFPMIH, CFPMM,

CFC Industrial Training

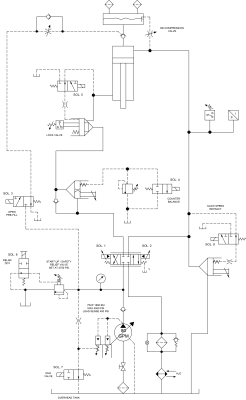

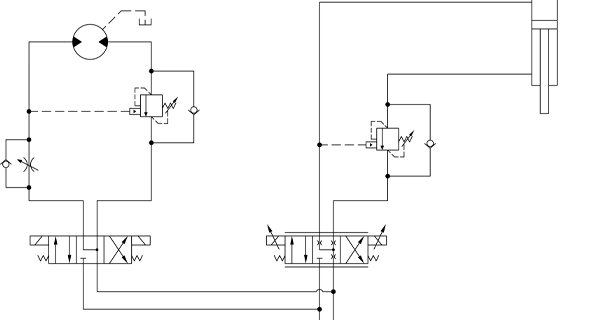

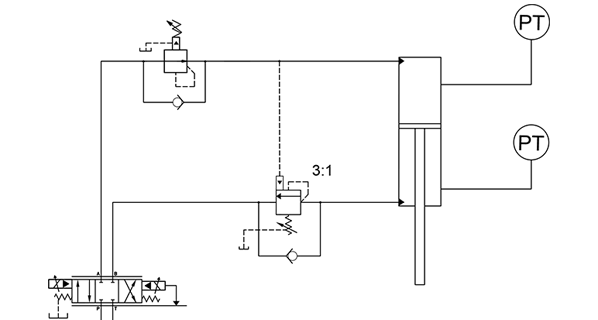

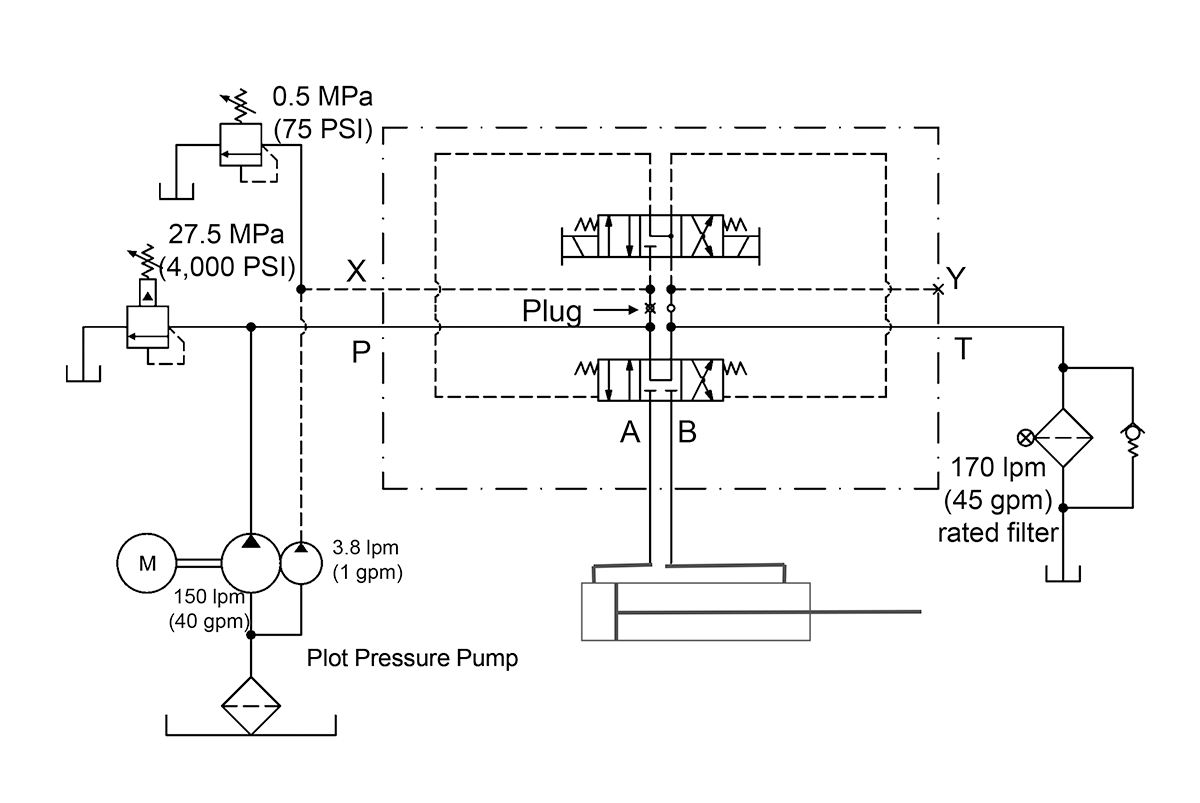

The attached circuit was designed and used by a new engineer recently hired by a hose distributor seeking to grow his business by designing and building small hydraulic systems for his existing customers.

The engineer was very conscious of excessive heat problems and used the small pilot pressure pump to reduce the heat caused by a 75 PSI check needed for pilot pressure. The cylinder was a 5” bore with a 3 ½” rod stroking 30”. The only problem was that his customer started to complain about the filter leaking and coming loose. He was told they had to turn the spin-on filter a small amount to tighten it, but it would start leaking again after several hours of operation.

Any idea what was causing the problem?

See Solution

Robert Sheaf has more than 45 years troubleshooting, training, and consulting in the fluid power field. Email rjsheaf@cfc-solar.com or visit his website at www.cfcindustrialtraining.com. Visit fluidpowerjournal.com/figure-it-out to view previous problems.