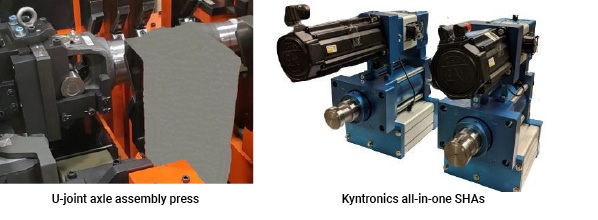

SHAs Improve Quality for Axle Maker’s Assembly Press

From Kyntronics

A heavy truck axle manufacturer launched a project to procure a horizontal assembly press for a new axle line from a special machine builder. The new line needed to achieve improved process quality for the assembly press station as part of a company-wide initiative to improve throughput and reduce rework. In addition, the axle manufacturer had a requirement to minimize the use of hydraulics in the plant due to the advantages of being environmentally cleaner, providing significant energy savings, reducing floor space, and quieter operation. The customers’ “minimal hydraulics” mandate created unique challenges for the machine builder due to the high forces required in the assembly press stations.

The machine builder considered using electromechanical actuators but found that the large size and high cost of the technology was prohibitively expensive and would not meet their project requirements. In addition, there were concerns about screw life due to the uneven “spike loads” to which the actuators would be subject during production.

After careful consideration, the machine builder selected the Kyntronics all-in-one SMART hydraulic actuators (SHA) for the horizontal assembly stations on the new axle line. The SHAs were rated for 45,000 lbf (200kN) of force and were provided in a parallel configuration that delivered the required force in a compact package fitting the available space envelope.

The SHA provides precise and repeatable control of applied force and position, which was critical for the quality standards required from the new horizontal press.

Rockwell Automation (Allen Bradley) servo motors and drives were used on the SHAs, which met the customers’ control specifications.

The Kyntronics SHAs implemented on the new horizontal press stations exceeded the requirements of the machine builder and end customer. The all-in-one feature eliminated the need for an HPU and hydraulic infrastructure on the new machine, resulting in less space required for the machine, a clean working environment, quieter operation, and substantial energy savings.

The precision force and position control of the SHAs exceeded the axle manufacturer’s stringent quality requirements and helped improve output of defect-free assemblies. The SHAs provided reliable, maintenance-free operation despite the uneven loads experienced during the assembly process.

The Kyntronics SHA combines the power of hydraulics with the precision of servo control, resulting in an ideal solution for the U-joint assembly process on the horizontal press.