New High-Precision Single Stroke Honing Process

Achieves High Level of Accuracy for Manufacturing

Sunnen Products Co. introduced a quantum improvement in a key manufacturing process for cast-iron hydraulic valve bodies using a precision Single Stroke Honing® process that achieves cylindricity/straightness under two microns in bores up to 10 times longer than diameter. Developed in Europe to meet leak-free requirements for high-pressure hydraulic systems, the process is almost 200% more accurate than anything previously achievable for long, small-diameter, tandem bores.

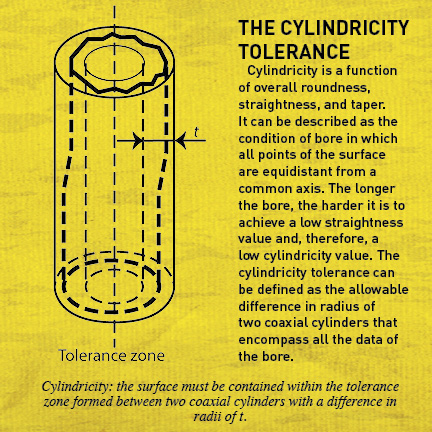

“European mobile equipment hydraulic systems established this cylindricity specification to reduce internal leaks and achieve higher valve performance,” said Juerg Huber, managing director at Sunnen AG. “The precise fit between the sliding spool and valve body maintains the internal seal in this area. Precision cylindricity and straightness in this bore ensures uniform clearance between the moving parts from top to bottom in the valve, allowing free movement of the spool without leakage around it.” (For more on cylindricity, see the image below)

Single Stroke Honing is a single pass process that sizes and finishes a bore with a series of progressively larger super-abrasive tools adjusted to a preset diameter. Single Stroke Honing tools rotate while passing through the bore one time and then withdrawing. The machine’s servo-controlled stroke system provides flexibility with adjustable speed and various feed profiles, such as pecking, short stroke, dwell, etc. Column feed and spindle speed can be varied throughout a cycle using the machine control.

The Single Stroke Honing tool consists of a tapered arbor with an expandable diamond-plated abrasive sleeve mated to it. The external profile of the sleeve is designed for the application. Single pass honing is ideally suited for solid bore parts with L/D (length/diameter) of 1:1 or less. Parts with much larger length-to-bore ratio can be honed under certain circumstances. Bores that have interruptions allow better chip flushing and reduce the load on the abrasive sleeve. In the case of cast-iron valve bodies, bore length-to-diameter ratios of 10 or greater can be single pass honed with great success.

The Single Stroke Honing tool consists of a tapered arbor with an expandable diamond-plated abrasive sleeve mated to it. The external profile of the sleeve is designed for the application. Single pass honing is ideally suited for solid bore parts with L/D (length/diameter) of 1:1 or less. Parts with much larger length-to-bore ratio can be honed under certain circumstances. Bores that have interruptions allow better chip flushing and reduce the load on the abrasive sleeve. In the case of cast-iron valve bodies, bore length-to-diameter ratios of 10 or greater can be single pass honed with great success.

“Single pass honing is a stable, high-production process that can achieve one-micron cylindricity in a short bore—one with L/D less than one—assuming the part has a sufficiently rigid wall,” explained Huber. “However, as the bore length increases, it becomes more difficult to achieve good straightness and cylindricity. Among other reasons, the honing tool’s sizing land tends to follow the bore. On cast-iron valve bodies with L/D of 10, the standard process has typically produced five-microns cylindricity under optimum conditions. High-precision single stroke honing takes this to two-microns cylindricity or less. And with a tool life that can be 60,000 to 80,000 parts, the process is economical. A typical part suitable for this process might have a 16-mm bore, over 160-mm long, with 11 lands. This type of part can now be honed to less than two-microns cylindricity, less than two-microns straightness, and one-micron roundness.”

The high-precision single stroke process utilizes a combination of proprietary tool processing, tool holding, workpiece fixturing, and process parameters without any penalty on cycle time. It is already in use by manufacturers of hydraulic valves in Turkey, Italy, Germany, Switzerland, Brazil, Sweden, and the U.S.

The Single Stroke Honing® Machine

Sunnen offers Single Stroke Honing on three different VSS-2 series models that incorporate up to six spindles to progressively size and finish part bores. The machines are ideal for precision sizing of bores 3.9 – 50 mm (0.149 – 2.0″) diameter in stamped parts, hydraulic valves bodies, gears and sprockets, parking pawls, rocker arms, turbocharger housings, and similar parts. Ideal materials include cast iron, powdered metals, ceramic, glass, graphite, and other free-cutting materials.

The VSS-2 has accurate spindle alignment combined with flexible, easy-to-use controls. Spindles are factory aligned independently for precision centering over the tooling plate to produce better bore geometry than possible when using an “average” alignment for all the spindles.

The VSS-2 has accurate spindle alignment combined with flexible, easy-to-use controls. Spindles are factory aligned independently for precision centering over the tooling plate to produce better bore geometry than possible when using an “average” alignment for all the spindles.

The VSS-2 utilizes a spindle carriage with a 724-mm (28.5″) stroke and up to 105-mm/sec (250-ipm) stroking speed for increased flexibility with a wide variety of parts and tooling combinations. The servo-powered stroke system provides process flexibility and is hand-wheel controlled for quick setup.

The menu-driven touch-screen control allows the column feed and spindle speed to be easily varied throughout the cycle. Process flexibility is enhanced by the use of six available profiles, including pecking, short stroke, and dwell, which are easily added to a setup. More than 100 setups can be stored. Additional I/O and memory are standard for integration with auxiliary equipment, such as robots or part loaders.

The VSS-2 Series 2 is available in three models—the 84 (eight-station, four-spindle), the 86 (eight-station, six-spindle), and the 64 (six-station, four-spindle)—to meet various mid- to high-production needs. Spacing between spindles is 190 mm (7.48″). The 7.5-kW (10-hp) spindle drive provides a speed range of 100-2500 rpm.

When properly applied, Single Stroke Honing is a quick, cost-effective method to get a precise bore size, geometry, and surface finish. Single pass bore sizing is also appropriate for splined bores or long L/D ratios if cross holes or other interruptions are present to allow chip flushing. Sunnen offers a range of single pass plated diamond tooling for the VSS-2 for precise, accurate, and consistent bore sizing.