Smarten Up

The year 2021 marks a decade since the concept of Industry 4.0 was introduced at the Hannover Messe trade fair in Germany. One year later, General Electric coined the term industrial internet. The concept of Industry 4.0 was a vision at the time, and the Industrial Internet of Things (IIoT) was on the horizon. In ten short years, we have arrived in an industrial era in which smart, digitally networked hydraulic solutions are a reality.

What do we mean by Industry 4.0 and IIoT, terms that are often used interchangeably? Industry 4.0 generally describes the latest industrial revolution, in which production and various processes are coordinated, integrated, and monitored by cyber-physical systems. These cyber-physical systems have computer technology at their core. Industry 4.0 is also a philosophy that embraces ongoing change, such as lean manufacturing.

IIoT grew from the beginnings of late-1960s automation with programmable logic controllers (PLCs) and robots. Today, the term characterizes the networking of technologies, including advanced sensors, digital drives, and other devices that lead to new process efficiencies.

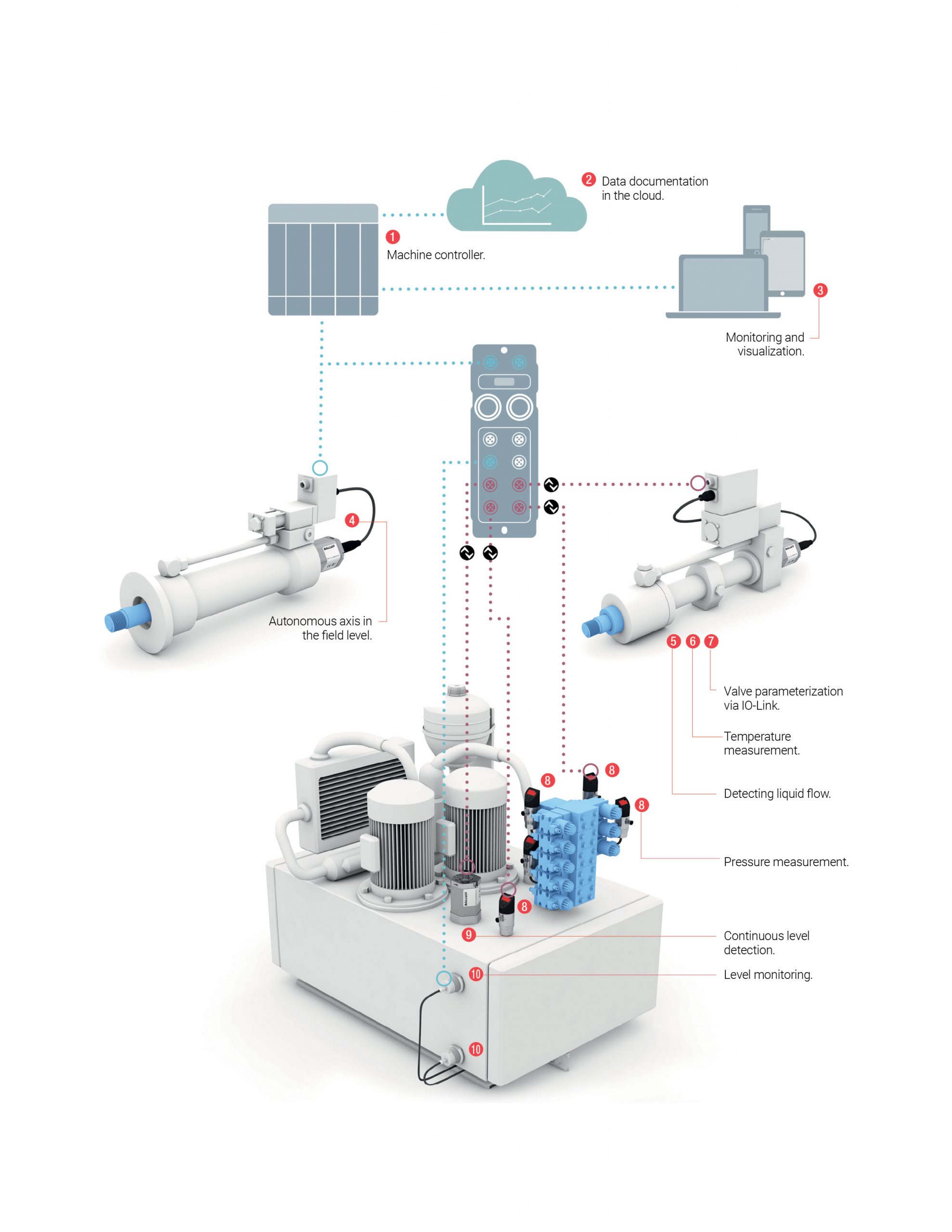

In fluid power, IIoT refers to smart sensor technologies that monitor temperature, pressure, flow, level, travel, and position in hydraulic cylinders. Systems share this data to provide information about hydraulic processes in real time. Additionally, they share information about components that can be analyzed and visualized to improve operations.

For example, a digital drive solution using IIoT might include temperature, flow, and level monitoring, along with pressure measurement; parameterization and communication from field level to the controller via the IO-Link communications standard; a machine controller; monitoring and visualization of the data on a PC; and data analysis in the cloud.

Systems that integrate smart hydraulics are used today across a wide range of industries, processes, and applications, including iron and steel, stamping in the automotive sector, the marine industry, offshore exploration and extraction in oil and gas, and offshore wind farms, among others.

Smart hydraulics increases efficiency on multiple levels, beginning at the individual machine level. In the wind-energy sector, for example, intelligent systems with smart sensors adjust the blades of wind turbines to harvest the wind optimally. Magnetostrictive linear position sensors provide hydraulic cylinder piston position feedback. We also find intelligent hydraulics in control valves and hydraulic power units.

Solutions such as these can be integrated into existing or new installations to increase efficiency. This allows you to easily upgrade analog systems with classical hydraulic systems.

When these pieces come together, they are more than the sum of their parts. They offer a systems-level understanding of work and work processes. Seeing the performance of individual parts can help you understand and optimize the system as a whole.

Increased safety is another benefit. Ultrafast feedback motion compensation is now being integrated into gangway systems, for example, to compensate in real time for movement caused by wave or wind conditions. Reduced energy consumption is another example. Manufacturers of systems for hoisting and transferring loads use smart hydraulic systems to store energy released during lifting and transferring by harvesting the upward motion of a vessel. The smart system recovers this energy from a hydraulic accumulator when needed during the downward motion. And digital drive hydraulics can reduce material use and waste, making installations cleaner and greener.

But some of the most significant benefits are in predictive maintenance based on precise condition monitoring, analysis, and modelling. Smart sensors continually acquire data, and analyze, diagnose, and visualize the condition in real time. This information is used to predict either the failure of a specific component or its working life, allowing you to act before failure and increasing equipment availability.

This helps you progress to a level of efficiency beyond timeframe-based preventive maintenance, such as every six months or after a certain number of actions. You can perform data-based diagnosis remotely. In an offshore wind turbine, for example, this can save significant costs and increase work safety because personnel spend less time traveling to turbines and diagnosing or repairing faults in precarious working conditions.

One recent and quite unexpected benefit of IIoT occurred when the COVID-19 pandemic struck and travel to work sites was difficult. The impact was softened for teams that could rely on sensors in the field to monitor facilities remotely.

Designing a smart system

Designing an IIoT-based system is a way of reckoning with your future needs. To meet those needs and maximize your short-term return on investment, consider several factors.

First, determine the parameters of the application or process so you can select the best IIoT components. Make decisions about the type of information to collect, how much of it to collect, and the resources required to manage and use this information. More information is not always better because information consumes network bandwidth and the attention of the system’s users and administrators. Setting IIoT requirements early helps identify which sensors can contribute to a smart system’s goals.

The devices must obviously be suitable for the process. Is the sensor sufficiently robust to withstand the cold of offshore applications in arctic conditions? Does a position sensor monitoring a hydraulic cylinder work properly when exposed to heat in the steel industry? Are heat shields or other protective measures necessary to mitigate the effects of ambient heat through conduction, conversion, or infrared exposure? Will sensors be exposed to liquids such as coolants, oil, and water, and do they have the ingress rating required for the task? Heat, cold, physical impact, shock, vibration, liquid ingress, the presence of corrosive chemicals, and high cylinder pressure are other factors to consider.

Sensor testing, according to IEC 60068-2, the international standard for the environmental testing of electromechanical products, offers good orientation. Building redundant sensors or redundant outputs into a process can also mitigate the effects of potential malfunction in extreme environments, allowing you to realize the benefits of predictive maintenance.

IO-Link

All of this data must be processed and analyzed somewhere. It might be in the control unit, edge computing close to the sources of the data, or computers in the cloud.

The method is generally determined by data rates, the volume of data, scalability to allow for increases in data volume, latency (delay times in the network), privacy and security, reliability, and, of course, cost. Consider the potential failure modes. For example, external

connectivity problems may arise that could make remote monitoring challenging. System complexity can be an added challenge

since complexity can require more training or more staffing. A large number of legacy devices – as is often the case in process industries – require the ability to integrate analog equipment into IIoT efficiently. This is possible with IO-Link, for example.

One way to reduce the complexity of your system is to use sensors built on the IO-Link protocol. IO-Link is an international communication standard (IEC 61131-9) that has become a key enabler of IIoT. Some compare its impact in industry to the dramatic changes brought about by the PLC and automation of the late 1960s. It has provided an enormous boost to industrial automation. Because of its simplicity and universality, it can make a drive or hydraulic system IIoT-capable.

IO-Link provides bidirectional, point-to-point communication between IO-Link devices located in the field (i.e., sensors and actuators) and an IO-Link master. The IO-Link master also provides the interface with the controller via existing networks or bus systems. Configuration and diagnostics can therefore be performed from a central location.

Process data about the devices and events are exchanged with digital signals, either generated as digital signals or converted from analog. Because they are digital signals, they resist interference and are free from noise. This makes it a strong communications basis for documentation, storage, visualization, and analysis of data downstream directly in the cloud or on an edge computing device. One of IO-Link’s many strengths is that it uses standard, unshielded three- or four-conductor cables. This lean wiring saves on the costs of installing complex and expensive cable.

IO-Link can be easily integrated into systems and is manufacturer neutral. Once connected to the master, IO-Link devices are recognized and configured with little effort. If an IO-Link device is replaced, parameters can be automatically written from the IO-Link master or controller to the device, simplifying maintenance.

Further optimizing IIoT

In 2021, 10 years on from the first tangible progress in Industry 4.0 and IIoT, we find ourselves in a rapidly developing networked industrial landscape. Components are becoming smaller, creating space that can be used to add multipurpose condition monitoring sensors to hydraulic components and processes. These can, for example, acquire and process data on vibration, relative humidity, contact temperature, and ambient pressure. The components then process this information in the sensor and transmit it via IO-Link to the host system, where it can be further analyzed, visualized, and used to create models.

The sensors also detect and communicate their own condition, informing operators about their temperature, number of operating hours, and start cycles. As with other sensors, they can be parameterized easily with IO-Link. While multipurpose sensors may not replace multiple single sensors in all relevant processes, we increasingly recognize their benefits, especially in noncritical processes where they are particularly cost-effective.

A great deal has been achieved in the development of smart hydraulics. But it is also a journey of shifting horizons. We can expect new gains in coming years as technologies bring us forward and our imaginations make new and better use of the information these systems provide. In this regard, we can expect smart hydraulic technologies to become smarter and deliver greater efficiencies in the future.