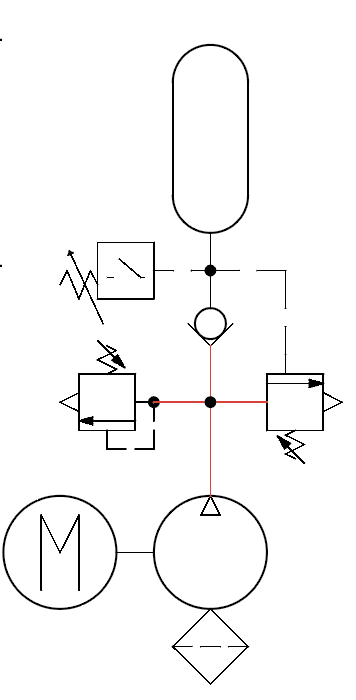

Starting an Air Compressor Under Pressure

By Ernie Parker, CFPAI, CFPSD, CFPS, CFPMM, CFPMT, CFPMIP, CFPMMH, CFPMIH

Many smaller inexpensive air compressors have a hard time starting up under pressure, especially in a cold building. A check valve right at the tank inlet bleeding down the line between the compressor and the air tank will make an easier startup, providing the line is properly sized. The problem gave you the following:

Many smaller inexpensive air compressors have a hard time starting up under pressure, especially in a cold building. A check valve right at the tank inlet bleeding down the line between the compressor and the air tank will make an easier startup, providing the line is properly sized. The problem gave you the following:

850 Nlpm (30.017 SCFM) @ 1000 rpm

3.73 KW (5 hp) not needed information

19 mm (.748”) diameter tubing

500 mm (19.685”) long

.7 MPa (101.5 psi) in the air tank

0 pressure in the line

No change in temperature

Calculate the pressure in the air line between the compressor and the check valve after just one revolution of the compressor starting up.

See the Solution