How to Handle Complex Lubrication Issues

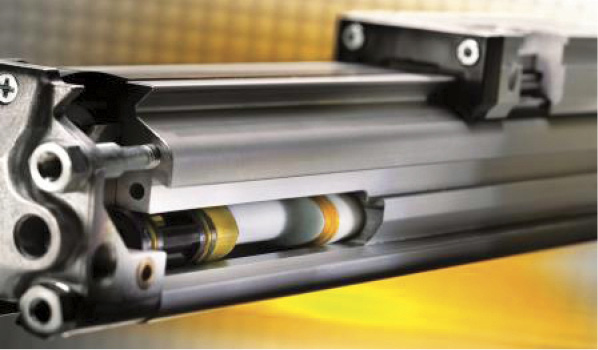

Cooperation Between Lubricant and Equipment Manufacturers Solves Pneumatic Application Problems Selecting the proper specialty lubricant for pneumatic …

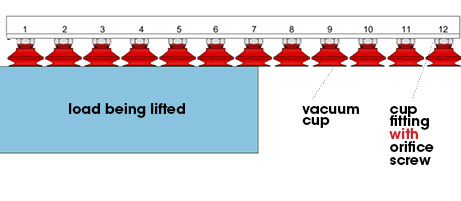

Minimizing Vacuum Leakage

In many vacuum-lifting applications, air leakage is experienced through interconnecting pipe work, porous product materials, or vacuum suction cups that are …

When to Replace a Pump

A frequent question in fluid power is “When should I replace my pump?” The answer is “It depends.” It depends on a multitude of factors, conditions, …

Safety First!

Select a Secure Circuit Design In fluid power applications, safety is the number-one priority in the design of a system. Vacuum lifting, as you can imagine, is …

Designing and Building a Machine for Energy Conservation

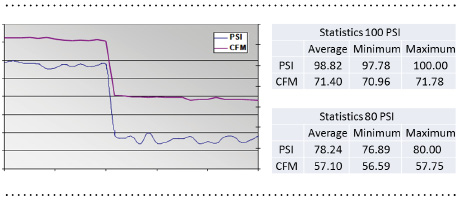

(and Convincing a Customer it is Worth it!) Machine builders and their customers are often at odds over machine pricing and how to address the costs associated …

Differential Pressure Transducer

The AST5300 wet/wet differential pressure transducer is for use in explosion-proof and non-incendive areas. Featuring all 316L and Inconel X750, the unit is …

Analysis of a Hydraulic Oil Failure

I recently conducted failure analysis and a reliability audit on a 300-kilowatt (400-hp) hydrostatic transmission. This hydraulic system was running a …

Money Wasted Due to Air Leaks

ONE THING I FIND in maintenance costs is money wasted due to air leaks that drive a compressor runtime through the roof and the electric bill along with it. A …

Keep That Pressure Under Control!

Machinery in a plant often operates at pressure settings higher than that actually needed to get the job done. Elevated pressure settings can cause excessive …

Why Is My Air Valve Leaking Out The Exhaust?

A customer purchased and installed a 4-way air valve, however air leaked continuously out the exhaust port of the valve just like the old one he was replacing. …