Hydraulic Accumulators Pre-Charge Maintenance

By Rao Choday, VP Sales & Engineering, Servi Fluid Power, Inc. A very common question asked by people in the fluid power industry is: How often should …

Filtration 200: Beyond the Basics

By Justin Bitner, Product Sales Manager at Eaton Filtration If working with hydraulics is part of your life, you’ve almost certainly been reading …

Preventative Maintenance on Roll Formers Saves Money and Time

Protect your investment & business by making time for maintenance Every investment is worth protecting. When you invest in machinery or equipment that is …

Proactive Maintenance 101: Define Your TOW!

The most important proactive maintenance exercise you can do for a piece of hydraulic equipment is to define its temperature operating window (TOW) and then …

Psst…Your Compressor Is Trying to Tell You Something

If you’ve ever been in your industrial plant during a shutdown, you probably noticed that your compressed air system was trying to send you a message. That …

A Planned Outage Spurs a Unique Approach for Turbine Maintenance

When power plant managers realized their scheduled window for a steam valve outage was challenging, engineers came up with a new tactic for servicing a dozen …

Begin at the End

I was recently at a conference addressing the issue of efficiency in fluid power systems, specifically in hydraulics. The conference was focused on existing …

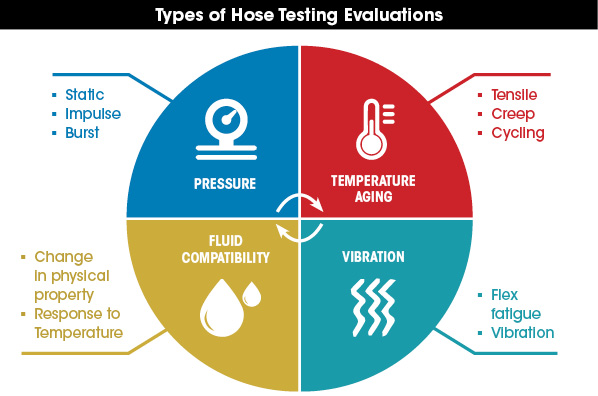

Hose Testing Methods for Optimal Performance

Predicting the life of a hose and determining the source of a failure can be difficult. Understanding how or when a failure occurs is time, temperature, and …

Storage of Pneumatic & Vacuum Components

The primary materials (excluding electronics) in industrial pneumatic and vacuum components subject to degradation under adverse conditions are the elastomers …

Take Your Hydraulic Systems Off Life Support

Contamination in hydraulic fluid is responsible for more than 80% of hydraulic system issues. The most cost-effective method of increasing the lifetime of …