The R-Drill Solution Enables Industrial Innovation

Raydiance, a provider of all-laser manufacturing solutions, announced the R-Drill, R-Tube, and R-Mill to address micromachining challenges in the automotive, industrial, and medical device industries. Ready to integrate into customer manufacturing lines, the new solutions increase yield and improve production efficiency by optimizing factory workflow to eliminate expensive post-processing steps and achieve part-to-part consistency. The products combine femtosecond laser technology with the company’s material-processing expertise and application-specific software.

Raydiance, a provider of all-laser manufacturing solutions, announced the R-Drill, R-Tube, and R-Mill to address micromachining challenges in the automotive, industrial, and medical device industries. Ready to integrate into customer manufacturing lines, the new solutions increase yield and improve production efficiency by optimizing factory workflow to eliminate expensive post-processing steps and achieve part-to-part consistency. The products combine femtosecond laser technology with the company’s material-processing expertise and application-specific software.

Spotlight on the R-Drill Solution

Regulations requiring improved fuel economy and reduced emissions are driving new engine technologies. These new requirements must be met while still satisfying customer demand for more powerful engines. Fuel-injector technology continues to evolve to meet this demand for better and cleaner performance. The R-Drill solution is suitable for manufacturing fuel injectors because it creates precise micro holes in a single process, achieving part-to-part consistency that has enabled customers to win new business and increase market share with engine manufacturers. The R-Drill enables industrial and medical manufacturers to

- capture production savings by drilling faster (<1 sec through 1.2 mm 316 SS) through thicker materials than the company’s previous commercial offerings;

- produce parts with intricate hole features not previously possible in an all-laser manufacturing process, including perfectly round holes, elliptical holes, square holes, positive and negative tapers, micron-sized entrance and exit features, and holes that alter shape and profile from the top to the bottom of the part; and

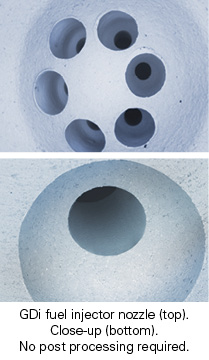

- eliminate months of iterative machine shop-based prototyping of new parts [e.g. gas direct (GDi) fuel injector nozzles] with the company’s 24-hour print-to-part software.

Commercial Application Example: R-Drill for Design and Production of GDi Nozzles

Automobile manufacturers are ramping utilization of GDi in next-generation engines to capture 20-30% fuel savings and realize higher emissions reductions amidst increasing regulations. Prototyping time for new nozzle designs is reduced from weeks in the machine shop to 24 hours with the R-Drill, dramatically accelerating design optimization and time to market. In addition, the R-Drill enables customers to reduce drilling time by approximately 30% while increasing yield to nearly 100%. The yield result is directly related to the part-to-part consistency delivered by the R-Drill, and there is no need for expensive post-processing to correct heat-affected zone (HAZ) damage.

R-Drill Features

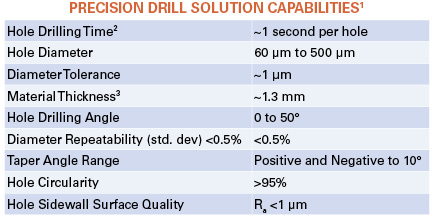

(Quoted values are for R-Drill solution equipped with R-300 laser.)

Performance:

- Power: 15W femtosecond laser

- Pulse Width: Reduced to <500 fs for higher peak power and elimination of HAZ damage

- Running Pulse Management: Start and forget, active pulse tracker ensures beam characteristics and process consistency.

- Fully Programmable: Accommodate part design changes or future parts by altering the software; no new capital required.

Results:

- Diverse Shape Profiles: round, square, or elliptical holes, positive and negate tapers

- Rapid Drilling: <1 second/hole for typical GDi hole geometries

- HAZ Elimination: No post processing required.

- Part-to-Part Consistency is unmatched by EDM or other laser systems.

Precision Samples:

For more information: Contact Raydiance at www.raydiance.com.

1Quoted values are for the R-Drill equipped with the R-300 laser.

2Quoted drill times are for a 200-µm-diameter hole in 250-µm-thick 440 stainless steel using R-Drill 300.

3Maximum material thickness is dependent on hole dimension.