Unlocking Efficiency: Vacuum Clamping for Diverse Applications

By Dane Spivak, President, Davasol Incorporated.

I have authored numerous articles on vacuum pick and place, a widely used application in fluid power circles for vacuum components. However, another common application for these products is material hold-down or vacuum clamping. Industries like sign manufacturing, glass production, fiberglass fabrication, aerospace CNC machining, and automotive trim finishing utilize vacuum hold-down. This article explores the basic methodology for achieving a secure, safe, and energy-efficient system for these diverse applications, emphasizing the need for rigid hold-down, ease of product capture, release, and cost-effectiveness.

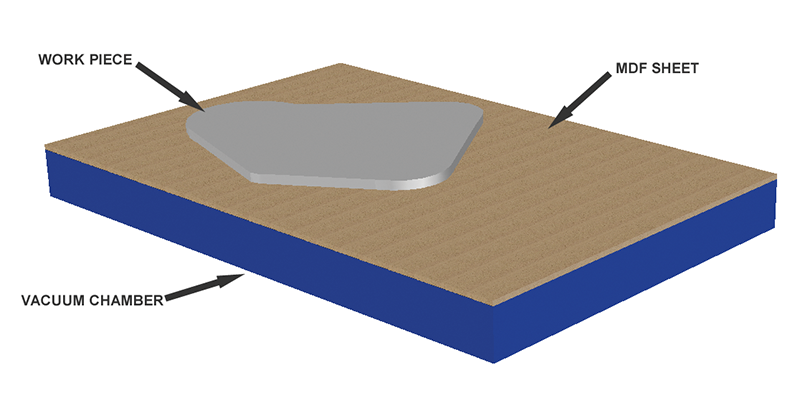

CNC routers, as shown in Fig 1, often use a porous vacuum bed made from porous MDF (medium-density fiberboard) for holding workpieces, like cabinet manufacturing. A large flow vacuum pump, typically an oil-free sliding vane pump or high-performance regenerative blower, connects to a chamber beneath the MDF sheet, creating a vacuum to secure the workpiece. The greater the surface coverage, the higher the vacuum level and holding force. As depicted in Fig 2. to minimize leakage, the uncovered MDF area may be covered with a thin plastic sheet.

Fig. 2

The holding force is determined by the vacuum level achieved. High flow pumps are employed, as seen in CNC routers, where the theoretical holding force per square inch is 64N at 100% vacuum. However, lower vacuum levels may reduce the holding force, necessitating additional measures like covering the open MDF area with plastic sheeting.

Fig. 3

Fig. 3.1

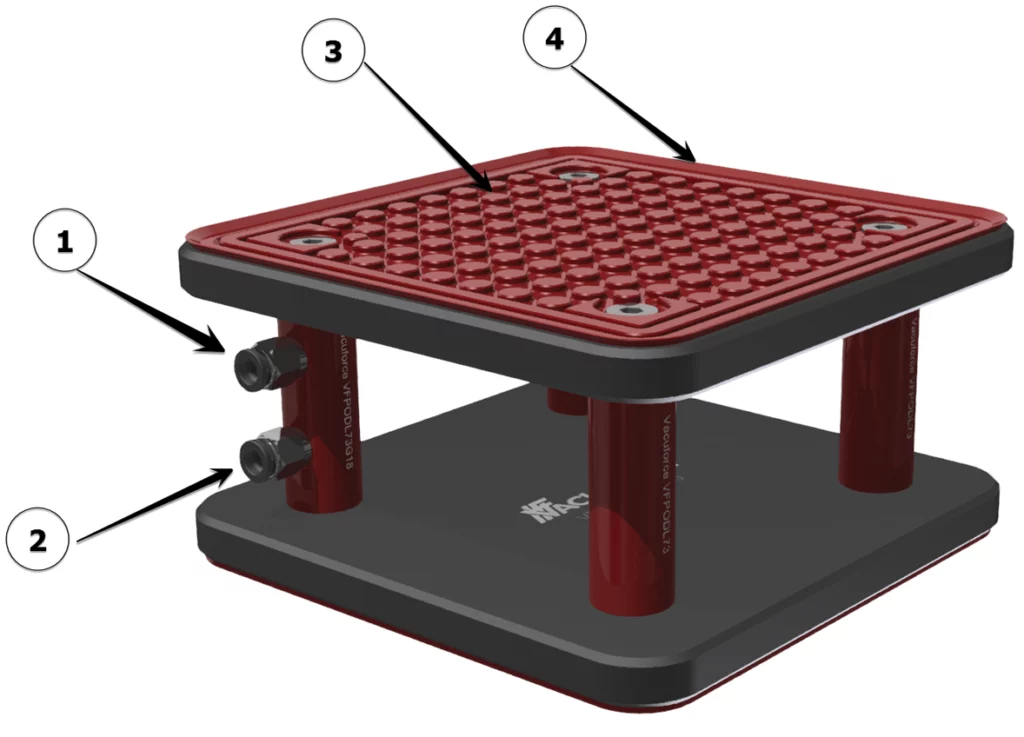

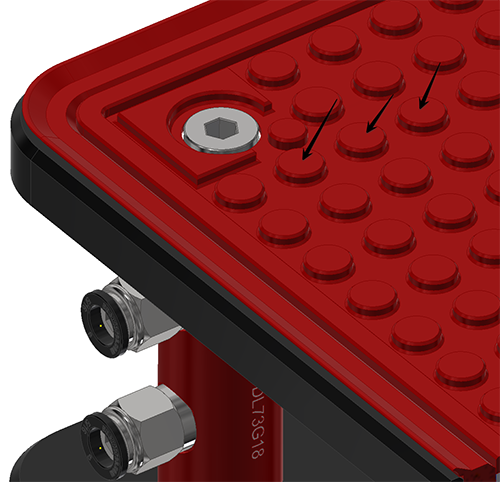

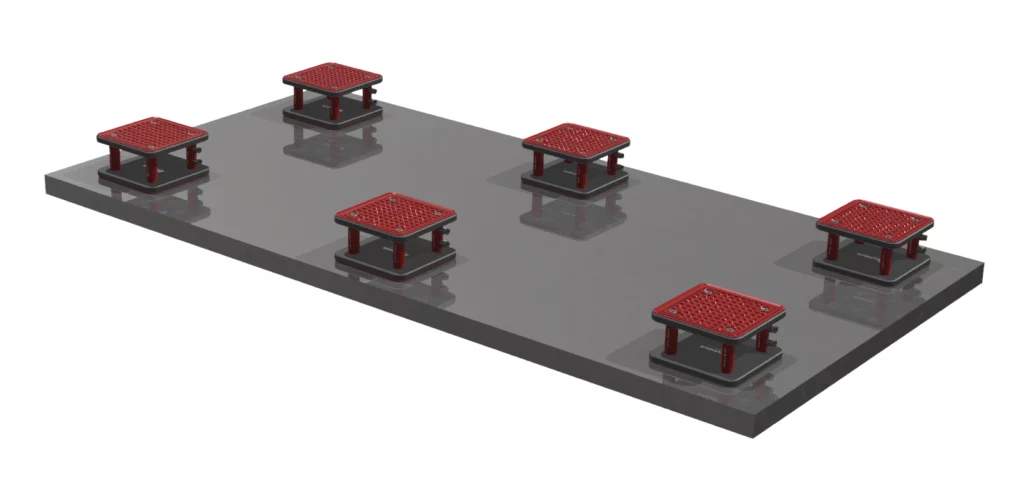

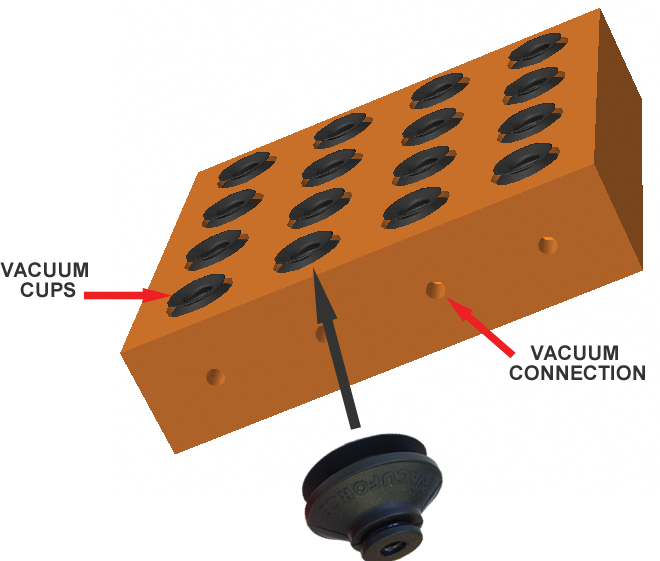

For applications involving parts with higher cutting forces, such as aluminum machining or marble and granite countertop manufacturing, vacuum “pods” (Fig 3) are commonly used. The parts of the pods are shown in this illustration. 1, vacuum port for workpiece, 2, vacuum port for machine table, 3, high lateral force grip pad (to prevent work piece of machine table movement in side load conditions from cutting tools) and finally 4, which is a vacuum seal to create the vacuum. These pods, connected to a vacuum pump or venturi, are used in groups as shown in Fig 4. In cases of thin sheets or non-flat profiles, custom vacuum beds or tools (Fig 5 and 6) may be required.

Fig. 4

The vacuum pod, illustrated in Fig 3, boasts a substantial holding force. In this specific example, the model measures approximately 200 mm (8 inches) square, resulting in a holding force of around 3200 N (719 lbs.) at 24” Hg (152Torr). Combining two of these units would naturally double the holding force to 6400N and so forth. It’s essential to note that machine coolant on the gripping surface could pose challenges by creating a liquid film, significantly impacting side load resistance. The cusp design of the vacuum pods, depicted in Fig 3.1, effectively mitigates this risk, facilitating the easy dispersal of trapped coolant at each node.

Fig. 5

Fig. 6

Fig. 7

End users often employ continuous “ON” vacuum pumps or venturis for long production cycles. However, for non-porous products like flat aluminum billets, turning off the vacuum once a safe level is achieved offers substantial energy savings. Fig 7 illustrates a multi-stage air-powered vacuum generator with an energy savings “kit” for efficient air control. This cycles on and off as vacuum is required or as the level falls due to a small leak. This can have considerable energy costs savings.

In summary, the landscape of vacuum clamping applications is diverse, with efficiency, user-friendliness, and operational expenses emerging as shared priorities. Through a thoughtful consideration of vacuum tool performance and the adoption of energy-saving practices, users can make well-informed decisions for optimal solutions. The provided examples shed light on various approaches to address the principles of vacuum clamping applications.

This article, a collaborative effort between Daniel Pascoe, President of Davasol Inc, and Vacuforce LLC, a leading manufacturer and distributor of vacuum components, provides valuable insights. For additional details, please visit www.vacuforce.com or reach out to Daniel at www.davasol.com or dpascoe@davasol.com. Stay connected with Vacuforce on twitter.com/vacuforce.