Vacuum Venturis: Air-Powered Generators

By Dane Spivak, Engineering Manager, Davasol Inc.

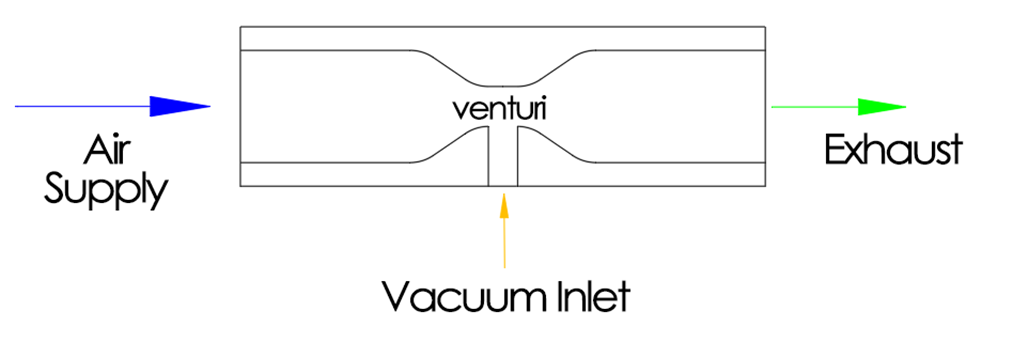

Do you ever wonder why it is hard to open a door when it is windy outside? The reason is vacuum is applied to the other side and pulls back against you. It is an example of the venturi effect, a fluid dynamics principle in which velocity creates a low-pressure point that induces vacuum flow. In simple terms, high-speed fluid can generate a vacuum. In this article, a venturi is a device that takes in compressed air and converts it into vacuum. A venturi can also be called a generator, an ejector, or an air-driven vacuum pump.

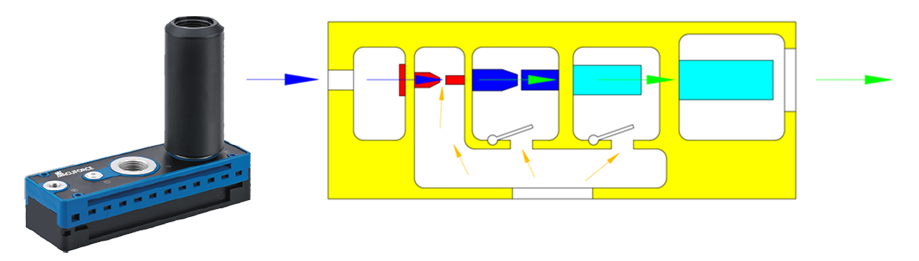

A generator produces vacuum when compressed air flows through a venturi nozzle, as demonstrated in figure 1. The decreasing diameter of the nozzle increases the air velocity across the cavity, which creates a low-pressure pocket. This low-pressure area “sucks” in surrounding atmospheric air from the vacuum inlet. A venturi must have at least three ports to function, including the compressed air source, vacuum port, and exhaust port, as shown in figure 1. A unit may have more ports for additional accessories, but it must include the aforementioned three.

Figure 1: Primary ports on a vacuum venturi.

The internal design of the venturi nozzle determines the performance of the unit. The shape, size, and curvature dictate how the compressed air travels through the nozzle to generate vacuum flow and final vacuum pressure. While we do not analyze nozzle designs in this article, it is important to understand why venturi models may perform differently. A typical air-driven venturi will need 60 to 90 psi (4 to 6 bar) of compressed air to operate at its fullest potential. The compressed airflow requirement varies depending on the venturi orifice cross-sectional area and how much air can pass through it. Manufacturers should provide data including the inlet pressure and flow required for their units.

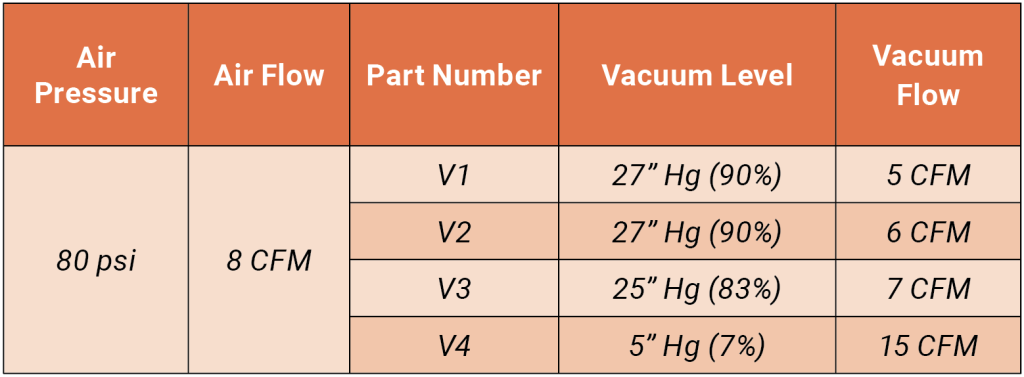

The vacuum performance can vary even if the compressed air-

supply conditions are equal. The energy of the compressed air can

provide higher vacuum pressure and less flow, or less vacuum pressure and more flow. Additionally, the overall design contributes to how effectively the compressed air generates vacuum. A poorly designed nozzle may create more turbulent flow, creating loss of vacuum level or flow. Table 1 compares four venturi units with the same compressed air consumption but different vacuum performance.

V1 and V2 generate the same final vacuum level, though V2 provides more flow. This means the design of the V2 nozzle is more efficient as it

Table 1: Venturi performances with the same compressed air conditions.

uses the same conditions to provide more flow. Comparing V2 to V3, V3 provides a slightly lower vacuum level but also more flow. So the nozzle design on V3 manipulates the compressed air differently and provides a different performance result. Depending on the application, V2 or V3 may be a better fit if vacuum level or flow is most important. Lastly, V4 has a low vacuum level and higher flow. Unlike the other models, the compressed air maximizes the flow. As a result, it sacrifices vacuum level.

The majority of venturi generator models have high vacuum levels, as it is often desirable for applications such as vacuum hold down, pick and place, leak and pressure tests, and others. The less common middle-to-lower vacuum level venturis reduce applied force in the application to maximize flow for material conveying or open-flow systems.

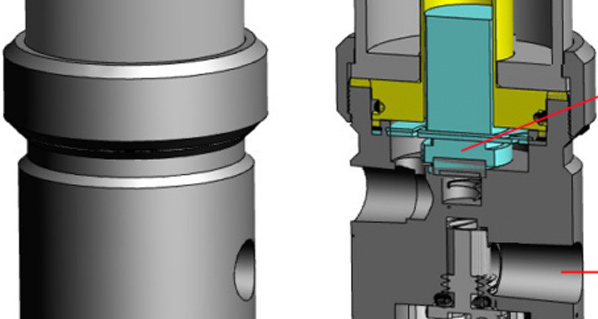

Up to now, we’ve discussed single-stage venturis. But there are also multistage generators, which contain more than one vacuum venturi nozzle, with two- and three-stage units being the most common. The purpose of more than one stage is to use the compressed air consumption more efficiently. After the compressed air passes through the first nozzle (red in figure 2), air is pulled from ambient through the vacuum port. Then this combined air volume flows through the second venturi (blue in figure 2) and through the third nozzle (cyan in figure 2). Therefore, the original air used in the first nozzle collects “free air” through nozzles two and three. This process allows for better vacuum flow to compressed air use, which is the reason multistage units are often the preferred choice over single-stage ones. Three-stage models are generally the cut off, as using air after three stages becomes ineffective.

Multistage generators typically power multiple suction cups, depending on how much vacuum flow is required, but smaller units may use single cups in vacuum pick and place.

Figure 2: Cutaway drawing of a three-stage venturi. The arrows show the air flow.

Table 2 compares the venturi stages. As shown, the air consumption and final vacuum levels are equal, but the flows are considerably different. This shows how powerful additional venturi stages can be in a vacuum system.

One might ask why all generators are not multistage units so that every unit is as energy efficient as possible. The short answer is single-stage models are smaller, easier to manufacture, and consequently lower in cost per unit. However, you could argue that the compressed air savings over time makes the multistage model more cost effective, which is

Table 2: Comparing one-, two-, and three-stage vacuum venturi performances.

often overlooked. As design and knowledge of the venturi continues to improve, multistage units are becoming more popular and recognized as a first choice.

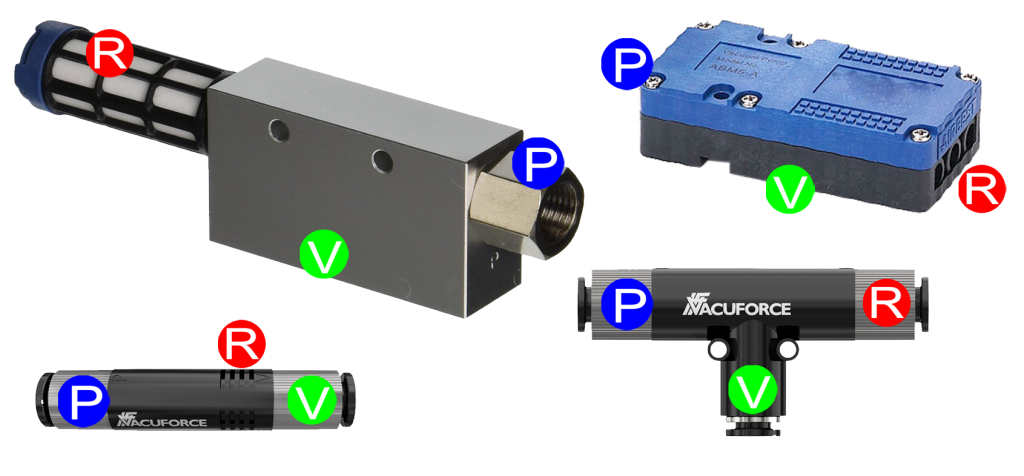

We have discussed the internals of the venturi, explaining how and why it works the way it does. In the real world, venturi performance must be connected and applied to the system using common connection ports. Looking again at figure 1, we know that each venturi body requires at least three ports, for air supply, vacuum, and exhaust. The air supply and vacuum ports are typically threaded or use a built-in push-to-connect fitting for ease of connection to the air lines. The connection ports are sized appropriately to allow enough flow to pass through, so it is crucial to not reduce the line size, which could restrict airflow into and through the venturi. Most generators come with an external silencer for the exhaust port, a built-in silencer, or a ported exhaust so discharged air can be plumbed elsewhere for release into the atmosphere. Figure 3 shows various venturi models.

Figure 3: Various venturi models, with the ports labeled P for pressure, V for vacuum, and R for exhaust.

Other than the three ports necessary for a venturi to function, some models have additional ports for gauges, sensors, blow off, or even multiple vacuum connections (see figure 4).

Figure 4: Venturi models with more than three ports, which are labeled P for pressure, V for vacuum, R for exhaust, and A for accessory.

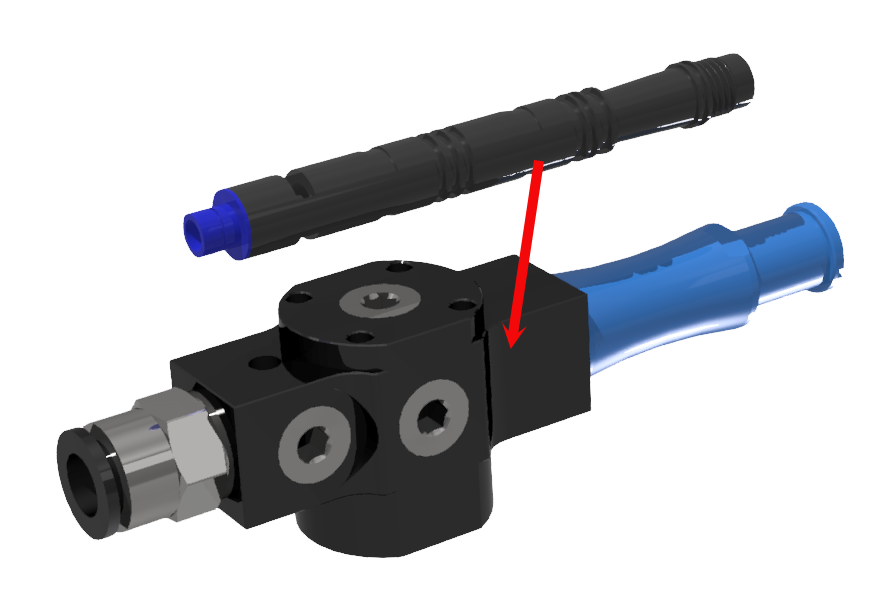

Venturi generator cartridges are an increasingly popular technology. A venturi cartridge is essentially a low-profile piece of a venturi nozzle that can be inserted and removed from a venturi body (see figure 5). Though proper pneumatic and vacuum filtration should always be implemented, it does not always occur. The cartridges help users maintain and clean the nozzles, which are easily accessed and handled, unlike traditional models that machine the nozzles into the body, making them inaccessible. Venturi cartridges can also be used for customized venturi body designs or built into a system such as a vacuum gripping end-of-arm tool.

Figure 5: Venturi cartridge.

The vacuum venturi comes in a variety of performance ranges and models. The nozzle design and number of stages impact its flow rate and vacuum level. With the possibility of widely varying parameters, the performance of a venturi should be reviewed and studied to select the right unit for each application. Ideally, users should consider professional assistance and manufacturer recommendations.

This article is the opinion of the author, Dane Spivak of Davasol Inc., an industrial brand management firm. One of Davasol’s clients, Vacuforce LLC, based in Indianapolis, partners with the author on this article. Contact Dane Spivak at dspivak@davasol.com.