All Around the World: Circular Sustainability for Fluid Power

By Michael Cook, Global Segment Director for Off-Highway & Segment Manager Fluid Power in the Americas, Trelleborg Sealing Solutions.

In today’s environmental and economic landscape, it is critical for fluid power component manufacturers and seal suppliers to incorporate sustainable methods into design, manufacturing, and production practices through design thinking for circularity and circular products.

For a long time, our economy had been a linear concept. This meant taking the needed resources, making a product, using it, and then, at the end of its life, sending it to a landfill or to be recycled. Until recently, sustainability focused on recycling and energy usage.

At the forefront of sustainability is the concept of product circularity and a circular economy. Circularity is more than developing a product that can be recycled; it is about designing extended value into a product, for the customer, for their customer, and for the first, second, and even third users of the product. It is not a step-by-step linear process with a clear end but a continuous cycle.

The circular economy

Seal suppliers and OEMs should consider the circular economy in the design phase of their products, materials, and solutions instead of using the traditional linear economy approach to manufacturing – taking a raw material, making it into something, and at the end of its life disposing of it. Creating circular products that last longer and use less energy, can be repaired, refurbished, or recycled, and have a useful second life supports the circular economy and sustainability. In a circular economy, OEMs aim to reduce waste through the reuse, recycling, and repurposing of a product. Leading component manufacturers do this through design thinking for circularity.

As opposed to a disposable design that has no consideration of what happens to the product at the end of its life, design thinking for circularity shifts the way products are developed. It is thinking about product design from the very start, with a desire to develop solutions that are part of the circular economy and designed with the environment and sustainability in mind.

Design thinking for circularity at Trelleborg Sealing Solutions is not about designing a product for recycling; it’s about designing seals that last longer, use less energy, and support easy repair and replacement.

It’s critical that seal manufacturers create high-performance seals with a long life so that customers replace them less often, resulting in less waste, reduced raw material use, and a greater return on investment.

High performance starts at the design phase. Seal manufacturers like Trelleborg model seal performance through finite element analysis and simulations across a range of application conditions and materials. This allows manufacturers to modify designs prior to testing, reducing the number of prototype loops, lowering development costs, reducing material waste, and speeding up the time to market. The extensive testing ensures seals perform as expected in an application.

Design for the environment

When possible, raw materials should come from sustainable and renewable sources. Regrinding production waste into a material blend for noncritical components such as wipers and wear rings gives this material a second life, reducing material sent to landfills.

By creating virtually leak-free seal designs, fluid power seal manufacturers minimize the risk of contamination to ground and water resources, protecting the environment from contaminants.

The extended product life of seals has a clear impact on sustainability. Fewer parts to replace means using fewer consumables and raw materials. The transport and logistics involved in moving parts and people to remote locations also have a massive impact on the environment. Extending product life reduces CO2 emissions in the supply chain.

When seal manufacturers provide robust lubrication management programs and technology, it reduces friction, wear, and heat generation in linear tandem sealing applications by allowing just the right amount of fluid film to reach the secondary seal and prevent dry running conditions. This reduces the energy needed to power the system and can support the downsizing of drive components, in turn reducing the overall amount of energy the equipment uses.

In rotary applications, Trelleborg uses Turcon Varilip PDR, a

single-acting low friction seal with no stick-slip. The seal provides long-lasting seal efficiency and can withstand dry running conditions. When compared to a standard radial oil seal, the low friction characteristics mean the seal uses less energy and lowers the risk of environmental contamination as a result of premature failure.

Modularity

Utilizing industry-standard design profiles and sizes ensures that designers and end users can easily specify sealing components, allowing the reuse of hardware designs. Standardization supports ease of repair, refurbishment, and reuse with readily available replacement parts, to give the hardware a second or third life.

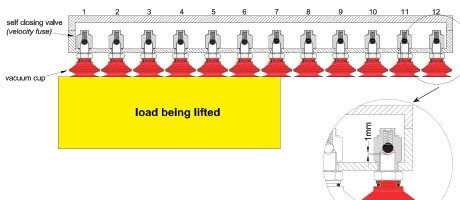

During the design phase of a seal, seal manufacturers work with customers to design solutions that can be easily disassembled to enable repair of parts. Seals that are easy to remove and replace minimize damage to equipment and reduce downtime.

The less material we put into landfills, the better. Methane gas that releases as waste decomposes in landfills creates a greenhouse gas that contributes to global warming and climate change.

When seals for fluid power applications are designed to last as long as possible, it reduces the need for replacement parts and the waste that gets placed in landfills.

Facts About the Circular Economy

- The earth takes almost 1.5 years to regenerate what we use in a year.

- After burning, 80% of waste from consumer goods goes to a landfill because of poor design or lack of end-of-life collection options.

- Over 80% of a product’s environmental impact is determined at the design stage.

- Currently, only 9% of our world economy is circular.

- Sixty to 70% of the world’s ecosystems are degrading faster than they can recover.

- We recycle less than 20% of electronic waste.

- Recycling electronics uses less energy in production and conserves resources like copper and aluminum.

Trelleborg Circular Product Designs

Here are two examples of circular product designs from Trelleborg.

Lightweight advanced composite materials. Trelleborg’s Automated Fiber Placement (AFP) technology is part of a special continuous-fiber manufacturing process that produces strong, lightweight components for a wide range of applications. This technology uses thermoplastic composite materials that are recyclable and suitable for repurposing at the end of life, unlike traditional thermoset composites.

Organically sourced materials. The development of bio-friendly materials using renewable plant-based compounds such as sugar cane and natural oils is something we are looking to explore in the future. These materials could allow Trelleborg to create sealing solutions that not only provide high-performance sealing with a long life but also use less energy and have a significantly reduced carbon footprint during manufacturing.