Revisions to ISO 11171: A Calibration of Automatic Particle Counters for Hydraulic Fluid Power Liquids

By Barry Verdegan, Ph.D., Research Fellow, Cummins Filtration Inc. and ISO/TC 131/SC 6 chairman

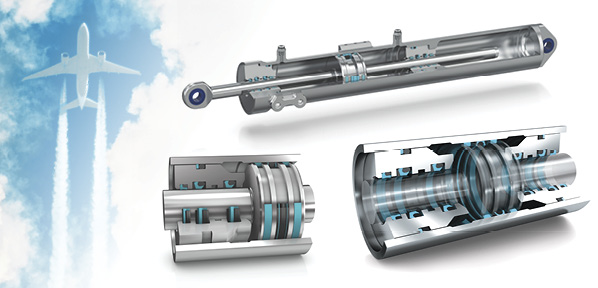

Hydraulic fluid cleanliness is critical to the overall reliability and efficiency of hydraulic systems. The fluid is both a lubricant and a power-transmitting medium. Reliable system performance requires control of the contaminants in the fluid. Liquid automatic particle counters (APC) are used to measure the concentration and size distribution of the contaminant particles in operating systems and to determine the contaminant removal characteristics of filters. Individual APC accuracy is established through calibration.

ISO 11171, Hydraulic fluid power – Calibration of automatic particle counters for liquids is a standard calibration procedure for APC that is used for determining particle sizes and counts. The primary particle-sizing calibration is conducted using NIST SRM 2806x suspensions with particle size distribution certified by the United States National Institute of Standards and Technology (NIST) for particle sizes 30 µm(c) and smaller, and using polystyrene latex spheres at larger sizes. ISO 11171 also provides for a secondary calibration method that uses suspensions of NIST RM 8631x or ISO Medium Test Dust conforming to ISO 12103 Part 1, which are independently analysed using an APC calibrated by the primary method.

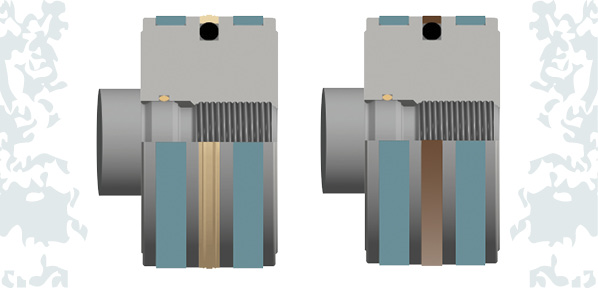

ISO 11171 establishes minimum APC performance specifications, including the APC coefficient of variation (COV) of sample volume, COV of flow rate, resolution, and particle counting accuracy. The operating limits of an APC, including its threshold noise level, coincidence error limit, and flow rate limits are also determined. Since ISO 11171 was adopted in 1999, particle size has been reported in units of µm(c). In 2016, however, ISO 11171 was modified to also permit reporting size in units of µm(b), referring to the use of SRM 2806b for calibration. The alternative means of reporting particle size and provision for mathematical conversion of µm(b) to µm(c) sizes is a response to a shift in particle size that occurred when SRM 2806b is used for calibration. The size shift is only an artifact of uncertainty in particle size distribution data obtained by SEM, but has significant practical implications for the industry.

A revision of ISO 11171 is currently underway by Technical Committee ISO/TC 131 Fluid power systems, SC 6, Contamination control to address these practical concerns. Changes being considered in the revision include:

- standardizing on µm(c) as the only acceptable unit of measure for reporting particle size;

- clarifying the definition of an APC;

- permitting other test dusts for secondary calibration suspension;

- using latex spheres for primary calibration at particle sizes greater than 30 µm(c);

- using secondary calibration suspensions for secondary calibration at particle sizes greater than 30 µm(c);

- using dilution of calibration suspensions to allow calibration of APCs at sizes smaller than 4 µm(c) that would otherwise be in coincidence error;

- introducing a tool for use to relate threshold voltage setting to particle size using the constrained cubic spline method of interpolation; and

- permitting the use of NIST RM 8631x, ISO MTD, or other ISO 12103 Part 1 test dust for secondary calibration suspensions.

In parallel with the revision, an international interlaboratory test is being conducted to determine repeatability and reproducibility using ISO 11171 to generate data to be used by NIST, to certify SRM 2806d as a consensus standard, and to generate data used to verify the counting accuracy. The round robin has been delayed because primary candidate material for SRM 2806d is not yet available. The testing will begin as soon as candidate material meeting NIST specifications becomes available.