Aluminum Framing – Everything to Build Anything

By Lori Bechtler, MGE/MPS Product Manager, Bosch Rexroth Corporation

With its sleek look and seemingly simple function, aluminum structural framing is versatile, practical and easy to use in a variety of applications, offering numerous advantages across multiple facets of an industry. The aluminum-framing portfolio provides everything to build anything.

A cost-effective solution

When compared to the alternative, aluminum framing is a cost-effective solution. Instead of using old-fashioned welded steel to build structures, aluminum framing components enable structures to be built faster and cheaper, saving companies time and money on both parts and labor. With dozens of bolt-together connectors and over a hundred different strut profiles available, structures for virtually any load or application can be quickly assembled without special tools or product expertise. Friendly to the environment, aluminum framing is reusable, making it simple and inexpensive to change structures as the needs of the application change.

Aluminum framing that already has a clean finish and an aesthetically pleasing design saves additional time and costs by eliminating the need for extra painting or another finishing to complete the task.

Lean manufacturing

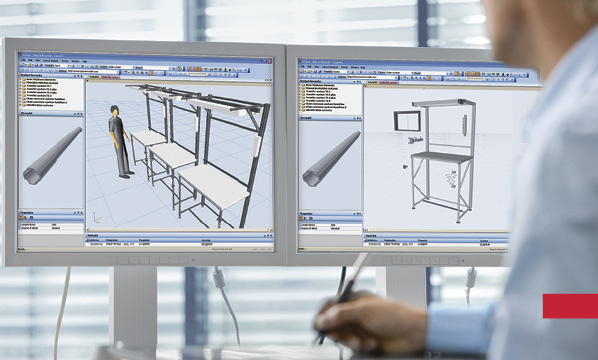

Aluminum framing also supports the people who interact with it on a regular basis. A prime example is the use of aluminum framing for manual production systems. Easy to reconfigure and robust enough to withstand hundreds of changes, aluminum framing helps increase productivity and worker comfort when its customizing capabilities are applied to workstations. This lean manufacturing mind-set yields benefits for manufacturers including reduced inventories, increased productivity, and faster time-to-market for new products, among others. Lean manufacturing also benefits workers by reducing job-related injuries and increasing labor productivity.

Versatile and resilient, aluminum framing can be used to make the workstations, flow racks, material shuttles and more, bringing companies closer to the higher productivity and safer workplace produced by a lean environment. Lean manufacturing puts an emphasis on cutting processes down to the necessities; it’s not promoting job elimination to achieve more efficient production. When implemented properly, the lean mind-set should have the worker’s benefit at the forefront, and the technology supporting lean should also support the employees using it.

Aluminum framing advocates for safer work environments. Easily assembled physical enclosures, guards and barriers protect workers and equipment from accidental workplace disasters. Aluminum framing companies often have safety experts who can offer insight on the best solution for an application.

What to build

The versatility of aluminum framing allows it to be used in a wide range of applications and industries, even applications from industries as strict as medical manufacturing. Cleanroom profile systems eliminate particulate-trapping surfaces, minimize out-gassing and enhance airflow for adherence to cleanroom and medical manufacturing regulations. Machine bases, material shuttles, tables, cabinets and almost anything else can be built for clean production with a full range of extrusions, connectors, and accessories uniquely engineered for a medical environment.

Outside the standard manufacturing environment, aluminum framing is also found in industries such as aerospace. Extrusions and connectors can easily assemble to create sturdy ladders, platforms and more for aircraft maintenance applications.

Aluminum framing fits into architecture too. It has taken the form of museum gift shops, a picture gallery, barges and fabricated housing, with more structures constantly being developed. It has made its mark on robust industries including semi-conductor, packaging, solar and others.