Basic Vacuum Pump Selection

By Daniel Pascoe, President, Davasol Inc.

There are many factors to consider when selecting a vacuum pump. This article explains the fundamental differences between three common vacuum pump technologies and offers the user a better understanding of those differences.

More often than not, a vacuum user will replace an existing vacuum pump with the exact same type of pump they have used before. Of course, if this vacuum pump works, then all is well, right? Possibly. However, just because the vacuum pump works for the application doesn’t necessarily mean that was the best pump choice.

The age-old saying “If it’s not broken, don’t fix it” is a common route to take, and understandably so. But if you have the opportunity to improve your system, due to a new installation or faulty pump replacement, then this is the time to get a better understanding of what is actually required of the new pumping equipment.

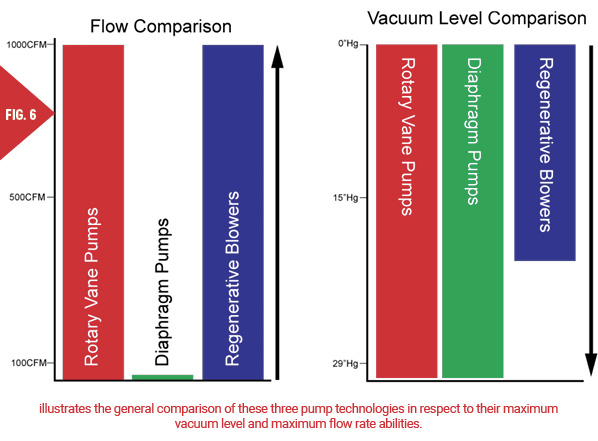

Let’s compare some obvious pump technologies with each other based on typical performance metrics, as well as the comparative advantages and disadvantages of using one type of pump over another.

Rotary Sliding Vane

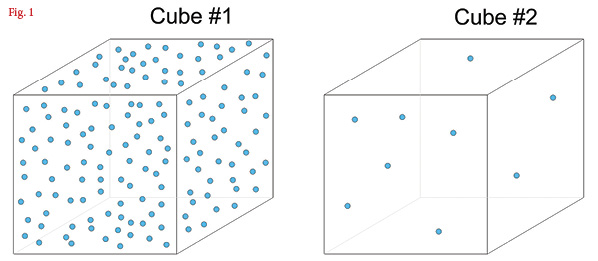

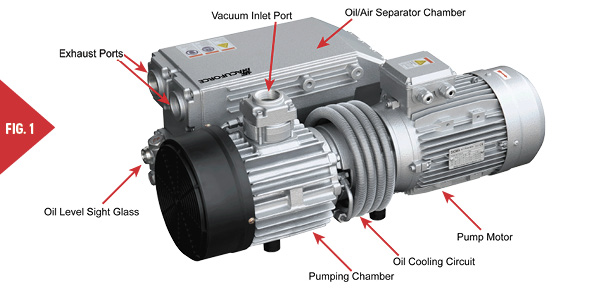

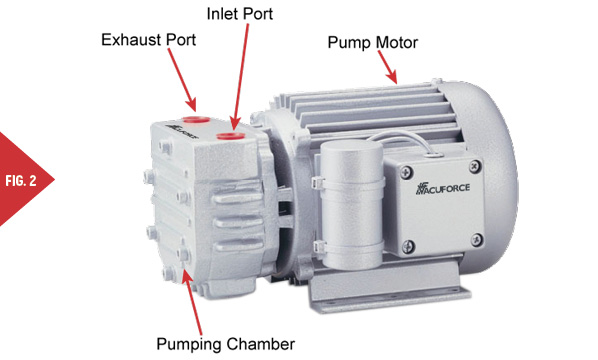

In general industry, rotary sliding vane pumps, as shown in Figure 1 and Figure 2, are very popular, offering the user a good vacuum flow choice ranging from only 1CFM to beyond 1000CFM. There are two fundamental choices of rotary sliding vane pumps: oil lubricated (Figure 1) and oil free (Figure 2).

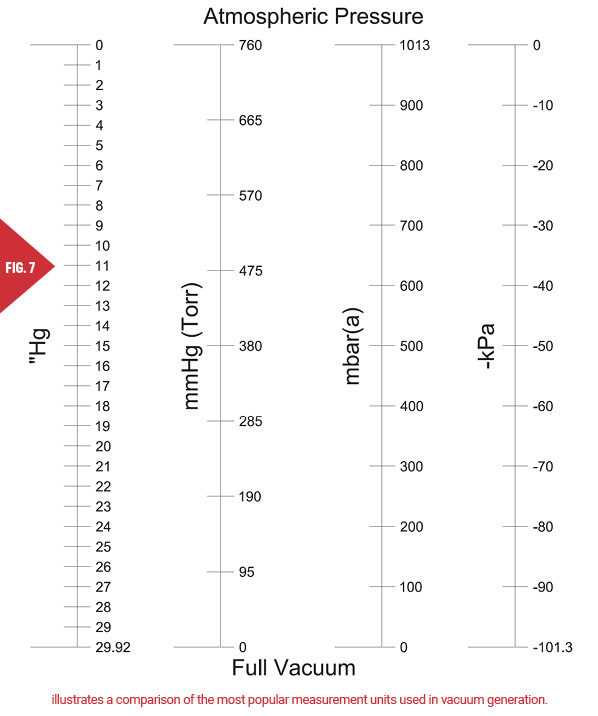

This description is self-explanatory, but one should be chosen over the other for one primary reason. If you need a higher vacuum level, then choose an oil lubricated pump. If you don’t need a high vacuum level and 27″Hg (which is the same as -90kPa, 100mbar(a), 76Torr, or 76mmHg) is adequate, then do not use a lubricated pump.

You might ask why don’t you use a pump that is capable of a high vacuum level, but use it at a lower one? A typical oiled vacuum pump requires a higher vacuum level to stay lubricated. Oil is “pulled” through the vacuum pump under the vacuum. Therefore, if you are using an oiled pump at a consistently low vacuum, particularly below 20″Hg, lubrication of the pump will be poor, possibly resulting in damage or even seizure.

Another reason is that at a lower vacuum level, an oiled pump could possibly start to “smoke” from the exhaust. This is because the amount of air passing through the pump at a low vacuum level is greater than what the pump’s internal air/oil separator is rated for. Consequently, excessive oil vapor is forced through the filter and creates an oil mist or smoke at the pump exhaust.

Just because you found an old oiled pump that isn’t being used doesn’t mean it should be. Understand what vacuum level you will generate before selecting a pump.

Don’t forget that it’s not the pump that determines the final vacuum level, it’s the application. If your application is sealed or dead headed without any external leaks from the atmosphere, then the pump being used will generate its maximum design vacuum level. However, if your system is not airtight—and most aren’t, such as vacuum cup lifting of cardboard cartons—then the pump may not reach its final design vacuum level.

If a vacuum system is not generating as high a vacuum level as it was the day before, it’s rarely the fault of the pump. Any air entering the vacuum system will decrease the final vacuum level being pumped down.

So rotary vane pumps—oil free models (not lubricated)—can be used in the majority of applications requiring a 20-27″Hg vacuum degree. Some examples include vacuum cup lifting, paper sheet conveying, end-of-arm vacuum grippers, universal vacuum tooling, and carton palletizing.

Oiled or lubricated vacuum pumps should be selected for applications where a higher vacuum level is needed, such as vacuum packaging of meats, cheese packaging, vacuum packed foods and similar products, degassing of liquids, adhesive curing, vacuum clamping, vacuum plastination, and vacuum molding. A typical maximum vacuum level of an oil lubricated rotary vane pump would be in excess of 29″Hg. However, using “Hg as the measurement unit is not appropriate as this is a differential vacuum level measurement. In higher vacuum level applications, an absolute scale such as mmHg or mbar(a) should be used. Most oil lubricated models will achieve an absolute pressure of 0.5mmHG or 0.5Torr. Some models, designed specifically for high vacuum process applications, achieve absolute pressure in the region of 1×10-2mmHg (0.01mmHg).

Diaphragm Pumps

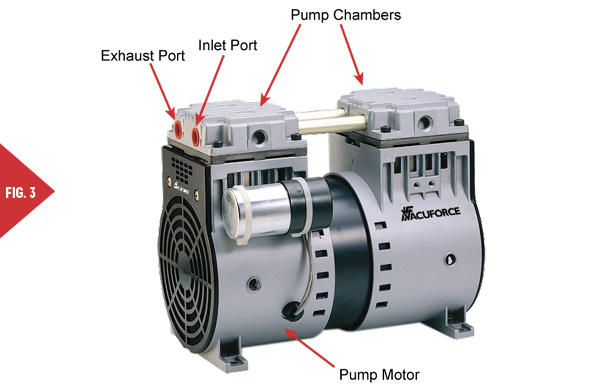

Diaphragm pumps, as shown in Figure 3, are normally associated with lower flow vacuum applications, such as standalone medical devices or dental surgeries. Although able to generate vacuum levels in the region of 28.5″Hg, they have a lower flow rate capability, compared to rotary vane pumps, topping out at about 4-5CFM. This is due to the oscillating pumping motion of the diaphragm. A rotary vane pump can spin incredibly fast and has a high surface speed (flow rate) at the vane tip. The reciprocating nature of a diaphragm pump might also be undesirable to the user in respect to the pulsating sound emitted.

However, many DC motor diaphragm pumps are ideal for mobile equipment as well as low voltage standalone machinery. The compact size of the diaphragm pump and DC motor option lends itself to mobile equipment in particular. The diaphragm membrane and pump head is available in a host of materials to aid the user application. Diaphragm pumps are often used in gas sampling applications where the pump “sucks” air in, then “blows” it out to be analyzed or tested with zero contamination of the media. This is not possible with rotary vane pumps due to oil contamination and vane wear particulates in oiled and dry pumps respectively.

Regenerative Blowers

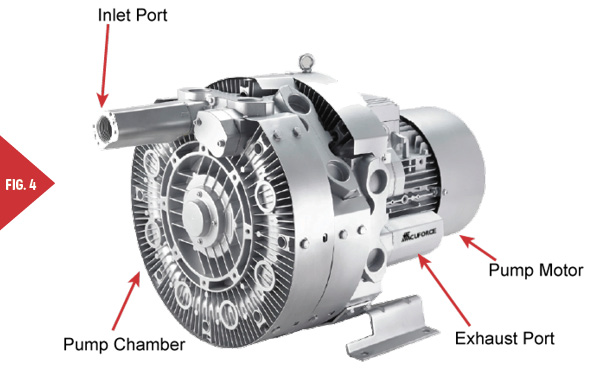

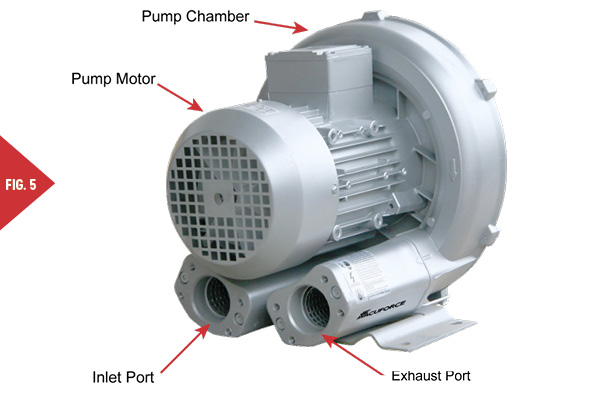

Regenerative blowers, as shown in Figure 4 and Figure 5, sometimes referred to as side-channel blowers, particularly in Europe, offer very large vacuum flow rates per kW motor power used compared to rotary vane pumps due to the high-speed impeller design. However, the final vacuum level achieved could be regarded as poor by some, particularly compared to diaphragm and rotary vane pumps.

Yet, the vacuum level is certainly not as crucial in vacuum lifting and material transfer applications as the vacuum level does not have to be very high. A single-stage regenerative blower as shown in Figure 4, has a typical maximum vacuum level of about 6-8″Hg, although some manufacturers offer 2- or 3-stage models with final vacuum levels in excess of 21″Hg. Figure 4 and Figure 5 show a single and a 2-stage model respectively. Notice the position of the exhaust port, which visually indicates whether the pump is single or 2-stage.

Regenerative blowers offer an operation that is virtually maintenance free except for the occasional bearing changes. When used in conjunction with the correct accessories, such as an inlet filter and vacuum relief valve, which bleeds air into the blower inlet to prevent “over vacuum,” these units offer many years of service. It is important to remember that just because a blower can generate a vacuum of 18″Hg does not mean it’s designed to do so.

This article is intended as a general guide and as with any industrial application involving machinery choice, independent professional advice should be sought to ensure correct selection and installation.

Vacuforce LLC, is manufacturer and distributor of vacuum components and systems for industry in North America. Vacuforce can be reached via their website at www.vacuforce.com, or directly at sales@vacuforce.com. Illustrations supplied by Daniel Pascoe of Davasol Inc., an industrial distribution branding company, who can

be reached at dpascoe@davasol.com.