On Busy Airfields, Hydraulic Valves Selection Matters

Fueling equipment, pressure protection systems, and even lavatory pumps benefit from guided piston valves

By David Locaputo, General Manager, Fulflo Specialties Co.

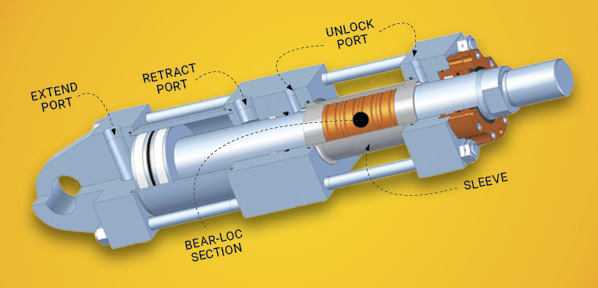

When selecting components for fluid systems destined for aviation defense applications, the type of hydraulic valve chosen can make a critical difference in the consistent operation of that equipment. Guided piston valves provide unique flow and stability characteristics for reliable performance without chatter. Whether installed to manage a machine’s automatic lubrication system or on the main line of aircraft fueling or lavatory pump equipment, guided piston valves offer several competitive advantages.

Advantage: Continuous Operation

Designed to operate reliably at pressures as low as 3 psi and as high as 1000 psi, guided piston valves reduce velocities through all but the controlling interface of the valve, thereby minimizing system power loss, and even preventing system shut down. The valves provide a constant line pressure unaffected by transient pressure surges, providing smooth and reliable line pressure.

Designed to operate reliably at pressures as low as 3 psi and as high as 1000 psi, guided piston valves reduce velocities through all but the controlling interface of the valve, thereby minimizing system power loss, and even preventing system shut down. The valves provide a constant line pressure unaffected by transient pressure surges, providing smooth and reliable line pressure.

Advantage: Self-Modulating

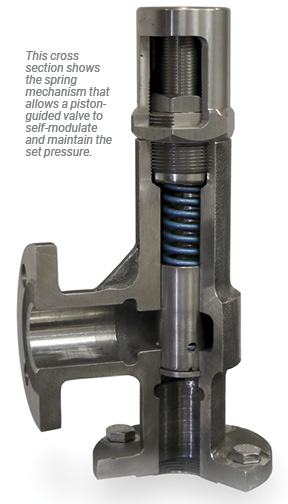

Since the guided piston relief valve is a flow-modulating device, pressure flow characteristics are completely different from spring loaded poppet or ball check valves. While a typical hydraulic valve has two operating settings: totally closed or fully open, a piston guided valve fluctuates on a spring to maintain the set pressure. It functions consistently, and modulates, at any degree of opening and closing. This self-modulation is pressure actuated and self-powered; it does not require any external sensing or control systems for operation.

Advantage: Immunity to Fluid Viscosity

Guided piston valves operate effectively with all types of liquids in the full range of viscosities, including hydraulic oils, water, solvents, and chemicals. For equipment destined for outdoor use, such as on an airfield, temperature can play a significant role as engine oil and hydraulic fluids thicken appreciably on cold days, and become less viscous on warm days. Oxidation, moisture, and ordinary wear can also contribute to significant changes in viscosity over time. The guided piston valve’s immunity to viscosity makes it an ideal choice for many types of applications, and ensures consistent operation regardless of viscosity fluctuation.

Advantage: Design flexibility

When designing fluid systems, there is always a trade-off between function and size, making the most of available space. A hallmark of the guided piston-valve is providing large flows without excessive bulk. Furthermore, as guided piston valves can be mounted in any position, without affecting performance, they can easily be worked into systems where space permits, enabling more compact equipment footprints. The availability of both screw and flange connection types further increases the range of installation possibilities.

Advantage: Quiet Function

Unlike ordinary direct acting relief valves, guided piston valves are less responsive to transient pressure surges, thereby eliminating the tendency to pound, squeal, or chatter. Quiet, stable, efficient performance is assured in both load regulation and system protection applications. With engines roaring and the clatter of other support equipment, the quiet of guided piston valves can significantly reduce equipment noise pollution on busy airfields.

Conclusion

With significant performance, design, and operating advantages, guided piston valves merit serious consideration for use in aviation defense applications. Whether designed into original equipment, or retrofit to replace underperforming valves, the advantages of these hydraulic relief valves can’t be understated.

About the Author: David Locaputo is the General Manager of Fulflo Specialties Co., a division of Ruthman Companies. Fulflo is a worldwide leader in the manufacture of hydraulic by-pass relief valves. Locaputo has more than 30 years of hydraulic valve engineering expertise and also serves as Corporate Operating Manager of sister Ruthman Companies division BSM Pumps.