Calculating Peak Flow

Elements furnished by Adobe Stock | Yakov

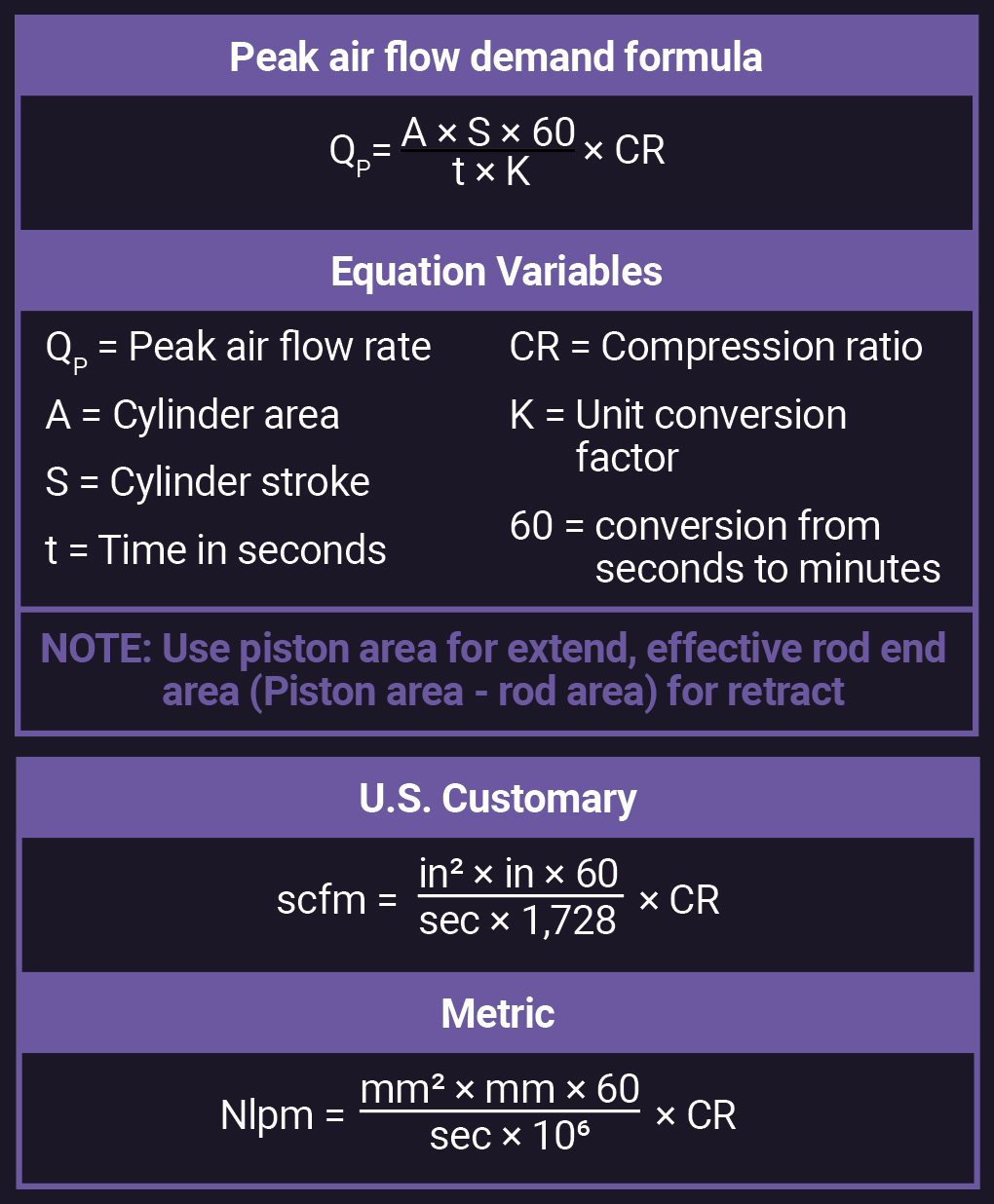

The flow rate to power air cylinders is computed for a specific operating pressure on the cylinder rather than from available air pressure at the compressor, which must be higher than is required to power the circuit. Thus, the operating pressure must always be higher than the load required pressure to account for frictional forces and for acceleration to a desired velocity or stroke distance per unit of time. Do not use the outlet pressure at the compressor because there will be pressure drops through the lines, valves, and other components that will reduce the available pressure at the cylinder. If there is a significant difference in the force requirements between extension and retraction, then the use of a dual pressure system should be considered to save energy. This operating pressure at the cylinder is the value used in the Compression Ratio (CR) calculation for the formulae outline below when calculating peak air flow demand. The CR factor in the equation determines what the free air requirement is for a given air flow demand. Again, lpm (cfm) refers to compressed air flow (displaced volume) in the cylinder and Nlpm (scfm) refers to air flow at standard conditions.

The stroke times or speed of the cylinder extending and retracting are important factors in calculating the peak air flow demand in nlpm (scfm) and this assists in calculating what the possible cycle rate could be. The cycle rate was used in the previous Outcome to determine the air consumption used for sizing the compressor capacity.

Solving for the peak air flow rate/demand to power an air cylinder with extension and retraction forces and cylinder speeds specified is a four step process:

Solving for the peak air flow rate/demand to power an air cylinder with extension and retraction forces and cylinder speeds specified is a four step process:

- Determine the pressure in each end of the cylinder to move the load, calculate the load ratio, and select the appropriate size cylinder to satisfy the load ratio guidelines.

- Determine the required stroke times based on the machine cycle requirements. This translates into a theoretical minimum speed that must be achieved.

- Solve for lpm/cfm based on the areas of the cylinder (extending and retracting) and the velocity.

- Convert lpm/cfm to Nlpm/scfm by adjusting for the compression ratio at the cylinder.

This information regarding the load pressures and flow rates may be used in calculating the directional control valve Cv necessary to size directional valve, connecting lines, and auxiliary components (filter/regulator, quick exhaust valves, and mufflers) if applicable.

It is important that the peak air flow rates/demand be used for sizing rather than the air consumption rates, as they are different and could lead to significantly undersizing the lines and valves. Undersizing would result in large pressure drops, would impact performance, and result in energy losses.

Test Your Skills

1. A double acting single rod cylinder with a 3 inch bore and a 1 inch diameter rod extends through a 24 inch stroke while producing a 400 lb force, and retracts through the same stroke producing a 500 lb force. If extension time is 2 seconds and retraction time is 3 seconds. How many scfm are required to power the air cylinder? Friction forces are included in the values given. Operations are occurring at sea level and only one pressure regulator is being used. Load ratio of cylinder is approximately 53% during extension and 75% while retracting.

a. 14 scfm extending and 24 scfm retracting.

b. 16 scfm extending and 21 scfm retracting.

c. 18 scfm extending and 19 scfm retracting.

d. 24 scfm extending and 14 scfm retracting.

e. 27 scfm extending and 12 scfm retracting.

See Solution