Hydraulics Predictive Maintenance: Should You Avoid It?

By Bryan Christiansen, CEO, Limble CMMS.

Predictive maintenance is an advanced asset management strategy that leverages condition monitoring and data analysis tools to monitor the performance of fluid power equipment. The monitoring tools collect different types of data that maintenance teams and process engineers use to build models and algorithms for early defect detection to predict when failure will happen and fix fluid power systems before they fail. Predictive maintenance equips companies with sufficient asset performance data for optimizing maintenance schedules.

Predictive maintenance relies on sensors to collect real-time fluid power equipment performance data. These internet-of-things sensors collect and transmit the data to centralized storage in real time. The sensors collect information about:

- Quality of fluids (does the oil or compressed air contain impurities?).

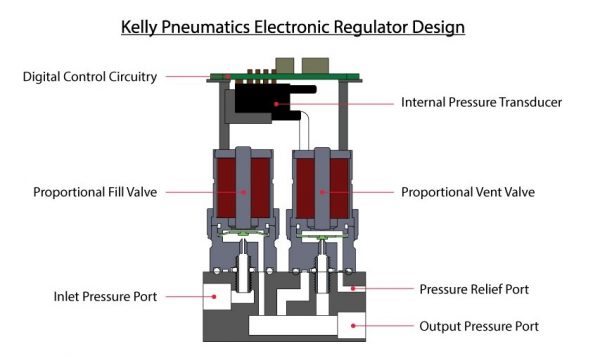

- Temperature and pressure variations.

- Fluid flow rates through the hydraulic or pneumatic systems.

- Quantity of fluid in reservoirs.

- System vibrations, emissions, and leakages.

- Surface cracks, wear and tear of cylinders, hoses, and other fluid power components.

Establishing a reliable predictive maintenance program requires seamless data transfer between fluid-powered assets and analytics tools. It implies companies should develop integrated systems in which sensors, industrial control systems, and enterprise software work collaboratively to collect data. This demands investment in secure digital networks, cloud technology, and advanced technologies like artificial intelligence and machine learning to improve data transfer and analysis speed and the accuracy of information obtained.

Should companies prioritize the implementation of predictive maintenance for fluid power systems? Failure of hydraulic and pneumatic systems destabilizes the operation of other production assets, which may result in significant financial losses for companies. These systems are costly to repair and replace. A predictive maintenance program is crucial for minimizing equipment maintenance time, reducing unscheduled breakdowns, and lowering the cost of maintenance.

Before setting up a predictive maintenance strategy, companies should evaluate the maintenance needs for every piece of hydraulic equipment in the facility. They must identify the metrics to track throughout the asset’s operating life to help select relevant sensors and develop predictive algorithms.

Predictive maintenance for hydraulics

Hydraulics systems experience wear, tear, and breakdowns due to the heavy presence of contaminants in hydraulic oils. Neglecting to replace hydraulic oil for an extended period causes the accumulation of suspended particles and water, which wears internal hydraulic components, leading to reduced system efficiency marked by significant power losses. The wear of components like hydraulic cylinder seals increases volumetric losses in hydraulic systems, causing leakages from cylinders. The hydraulics become ineffective in achieving their desired performance levels. Additionally, valves may become blocked, rendering the hydraulic system unreliable for its intended purpose.

Rectifying hydraulic systems is costly and time-consuming. All hydraulic components should operate perfectly to support other production equipment or systems. Some hydraulic system malfunctions are hard to diagnose and may demand an overhaul of the whole system. It becomes more complex if the system breaks down without warning. Damage to hydraulic systems may extend to other critical assets or cause damage to unfinished products on the production line. Additionally, maintenance teams must inspect all hydraulic components, some of which are inaccessible.

Implementing predictive maintenance is becoming inevitable as the world ushers in Industry 4.0. There is a significant focus on implementing data-driven operations in different industrial operations. A predictive maintenance strategy optimizes the performance and health of the hydraulics. With such a strategy in place, process engineers can identify the slightest changes in the operating conditions of hydraulic systems. Installed sensors can detect increased system vibrations, which may signal blocked valve spools or clogged hosepipes. The intelligent systems also generate alerts when the flow rate drops, the temperature and pressure of the hydraulic oil fluctuates, or leakages occur around the cylinders.

One area where predictive maintenance proves beneficial in hydraulics is monitoring the quality and quantity of hydraulic fluids. Aging hydraulic oils increase component wear and reduce the load-bearing capacities and responsiveness of hydraulic cylinders. That makes it mandatory for companies having large hydraulic systems to monitor oil cleanliness, lubricity, and quality. The predictive algorithm identifies any changes in oil quality and alerts maintenance personnel early to undertake mitigation measures to prevent extensive damage to the hydraulic system.

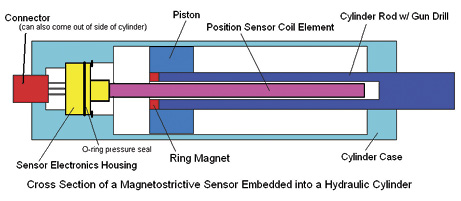

Companies can also install different position sensors around hydraulic cylinders to monitor the real-time positions of plungers during operation. These sensors can also be customized to facilitate autonomous rod inspections. Companies can check for surface dents or scores that may impede the performance of hydraulic systems. They can also fit clogging sensors to monitor the effectiveness of hydraulic sensors and maximize the purity of hydraulic oil flowing through the system.

Using predictive maintenance for hydraulics has several benefits. It enhances operational predictability by ensuring the maximum availability of fluid-powered assets. Companies can detect system anomalies earlier and implement appropriate corrective measures to minimize breakdowns. It improves system diagnosis and troubleshooting, ensuring accurate maintenance interventions are implemented. Such measures prevent volumetric losses, which increase the demand for pumps and raise energy consumption costs.

Predictive maintenance enhances maintenance schedules and can optimize maintenance budgets. Companies can optimize hydraulic oil change schedules, replacing them when the system identifies the earliest signs of deterioration. This gives a more precise oil replacement schedule, helping maintenance teams manage tight maintenance budgets better. The company can also identify common hydraulics failures and their causes. The availability of periodic maintenance data and real-time equipment maintenance data simplifies root cause analysis, failure mode and effect analysis, among other critical maintenance analysis interventions. That way, companies can resolve the most pressing hydraulics maintenance issues.

Predictive maintenance streamlines inventory management. Maintenance teams gain a clearer picture of the replacement parts and tools needed for scheduled repairs and component replacements. This prevents the company from holding obsolete or excess stock, which ties up huge sums of money. Hydraulics designers can analyze long-term maintenance and performance data to identify design loopholes that increase failure rates or raise demand for component replacements. They use this information to optimize system design and ensure design components are compatible with particular industrial applications, hydraulic oil grades, and operating cycles.

Appropriate for all hydraulics?

Although predictive maintenance proves beneficial in several ways, there are a few instances where the cost-benefit analysis is skewed. Industrial systems rely on hydraulic systems of varying sizes. It makes economic sense to implement predictive maintenance for large and complex hydraulics. However, smaller units can be managed using alternative maintenance strategies.

Establishing a predictive maintenance program requires process engineers to develop equipment-specific anomaly detection systems. They do this by studying equipment performance patterns over an extended time and determining which metrics they should measure and how they impact maintenance interventions. It implies companies spend substantial sums of money to identify, acquire, and install data collection tools, develop relevant anomaly detection algorithms, and streamline alert generation and quality of prescriptive analytics.

Modern technologies improve data collection and analysis. Companies can develop machine-learning models to identify equipment performance patterns automatically. The advanced systems can identify unique machine behaviors, some of which are difficult to track using manual methods. Engineers should develop befitting graphic user interfaces for these complex condition-monitoring systems. With them, human experts can visualize different data streams and make informed maintenance decisions.

It may be untenable for companies to develop such programs for small, stand-alone hydraulics, considering the requirements for developing predictive maintenance. These are systems whose failures can be managed using regular preventive maintenance. The number of parts under observation is few and can be monitored using readily available maintenance tools.

Alternatives for hydraulics

Companies can leverage preventive maintenance if predictive maintenance is too costly or the company lacks supportive technologies. Preventive maintenance involves all regular interventions performed on hydraulic systems to prevent failures. Maintenance technicians perform these tasks within fixed timelines, irrespective of the prevailing equipment conditions. Such measures include:

- Inspection of hydraulic hoses, reservoirs and hydraulic instrumentation.

- Sampling hydraulic oil, oil top up, and regular oil replacement.

- Monitoring hydraulic oil temperatures.

- Changing or cleaning hydraulic oil filters.

- Visual inspection of cylinders, plungers, and seals.

Sometimes, emergency breakdowns occur despite strict adherence to preventive maintenance schedules. Companies should establish reliable corrective maintenance measures to combat emergency breakdowns to minimize production downtime. This should outline how to allocate workloads among employees, emergency spare parts and tool acquisition, and desired turnaround times, depending on the complexity of the breakdown.

Predictive maintenance tools assist maintenance teams to interpret equipment performance data and maximize the availability of multiple hydraulics. The strategy ensures maintenance is data-driven, helping companies to manage lean maintenance budgets, maximize asset availability, by tracking loss of fluid lubricity, component wear and tear, and leakages. The idea behind predictive maintenance strategies is to detect fluid power equipment defects in time to avert potential breakdowns. It also simplifies equipment troubleshooting and diagnosis, making maintenance cheaper and more accurate and manageable.

Companies relying on large and complex fluid power systems should consider developing customized predictive maintenance programs to streamline asset management. They should audit facilities to identify equipment-specific maintenance needs and determine technological and sensor requirements to ensure seamless maintenance. These companies should also establish emergency equipment repair measures to address fluid power assets that may not be part of the predictive strategy.

For more information, visit https://limblecmms.com/.