The IFPS Certification Challenge

Are You As Well Rounded As You Think You Are?

If you are one of those individuals who are convinced that you know everything there is to know about fluid power and that there is nothing more to learn, you can stop reading now and go find something else to do. If you want to learn more about the industry, make more money, or be of greater value to your employer but don’t think you should have to expend any time, effort, or money of your own to do so, you might want to get going now so you can car pool with the know-it-all. And lastly, if you are a business owner or manager who just doesn’t think it is worth investing in training or certification for your employees, maybe you can catch up with the other two and complain about the weather together. If you are still reading, great! I hope to share some thoughts that might cause you to view things in a different way.

When I took my first job at a distributor in 1986, it never really occurred to me that fluid power would be—even could be—my career for some 26 years (so far). I remember well those early days of constantly tailing my boss and asking all sorts of dumb questions (and yes, some were really dumb). At the time, I was not motivated by any reason other than to convince him to pay me more money. I think partially from the frustration of dealing with me and maybe in some appreciation that at least I was trying, he gave me a copy of Womack Industrial Fluid Power, Volume 1. Neither of us realized it at the time, but with that simple gesture and a little encouragement, he set me on the path that would become my lifelong profession and in as much as an occupation can be (other than guitar-slinging rock star or power forward in the NBA), my passion. From that, I made up my mind then that I wanted to learn as much about every aspect of fluid power as possible.

Throughout the course of my career, I have encountered many people with varying skills from whom I have learned, by whom I have been influenced, and around whom I have modeled myself. Not just in copying their way of doing things, but also in emulating their methods of thinking and how to approach a task. Several times along the way, I heard of individuals being referred to as the “expert” or “guru.” After getting to know a number of these people, I began to ask myself, what exactly is an expert? Is it the counter person who has every part number in the hose and fitting catalog memorized? Is it the mechanic who can tear down, rebuild, and test a pump without having to refer to the repair manual or parts list? Is it the service tech, armed with only a couple of gauges and a flow meter, who can diagnose a seriously malfunctioning machine and get it operational again when others have failed? Is it the engineer who can design a system using all of the latest technology that will all but stand on its head? All of these individuals are certainly authorities in their own right, but do any of these skills singularly constitute being a true fluid power expert? Well, yes and no…and here is what I mean.

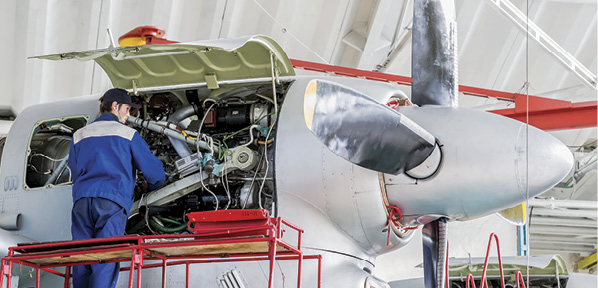

To boil it all down, it doesn’t matter if you have been in the industry six months or thirty years, to advance your career and become that well-rounded fluid power “expert”, you must have some skin in the game.In any piece of machinery—mobile or industrial—there is a life cycle. I do not mean its life span, although that is true, too, but a specific series of sequential events that define how it all comes together. More often than not, this sequence starts with the equipment salesperson and the customer defining exactly what is required for the machine functionality and serviceability. Sometimes, these persons may not be fully appreciative of the nuances of fluid power. From there, machine design concepts move to the engineering and component selection phase and continue on through manufacture, factory testing, in some cases installation and commissioning, operation, maintenance, and eventually, repair. Anywhere along the way, any shortcoming in the design or manufacturing that impacts any of the others may require modification or repair to realize a more robust machine design. In a large OEM or service/repair setting, these tasks are likely to be carried out by different individuals with varying skill sets and degrees of competence, each as critical to the success of the project as any other. In smaller, more specialized companies, a single individual may have the responsibility for supporting several or even all of these activities.

In today’s highly competitive manufacturing and service environment, machine and equipment uptime is critical and more often than not, a determinate to the success and survivability of a company. Downtime is the death knell of profitability. Perhaps the most important persons in this metric are the mechanics and technicians. The wide range of skills required from the individual to keep a machine operational or to get it running after a breakdown is significant. This person must have an understanding of mechanics, hydraulics, pneumatics, and increasingly, electric and electronic controls. That is a tall order by any standard.

Some of the best engineers with whom I have worked with are those who have a significant background or started their careers in troubleshooting and repair. They have seen what works, what doesn’t, and what to do about it. They have a keen understanding of what it means to design and package an energy efficient and safe system for minimal maintenance, reduced downtime, and repair with the fewest tools. They understand firsthand the need for and the value of proper and thorough documentation.

In other words, the engineer designs, the test technician tests and troubleshoots, and the mechanic fixes, and all of these skill sets are critical. In the context of the overall success of the project, none is exclusive or more important than the other. Experts must be knowledgeable in the many aspects of fluid power: hydraulic, pneumatic, as well as basic electric and electronic controls.

Becoming a well-rounded fluid power expert does not end at a particular destination; it is a continuing, career-long journey. It requires the self-challenge to constantly seek out the opportunity to learn by engaging others with more or different knowledge and skills than your own. It demands stepping outside of your comfort zone and taking on the challenges that others may avoid. It involves extra time and effort that perhaps you would rather spend doing something else. One must read from textbooks, fluid power periodicals, and as boring as it sounds, component manufacturers’ catalogs for no other reason than to gain knowledge of the types of hydraulic and pneumatic hardware in the marketplace, how they work, and how they do not. To gain additional knowledge, one should consider taking a community college course or technical seminar in a discipline where his or her skills are weak. To boil it all down, it doesn’t matter if you have been in the industry six months or thirty years. To advance your career and become that well-rounded fluid power “expert,” you must have some skin in the game.

Okay, I am guessing by now that I am preaching to at least some of the choir, but you may ask, what does this all have to do with me? What does this have to do with certification? To keep pace with the broad and ever-changing needs of industry, the International Fluid Power Society provides many specific and complementary certifications to demonstrate core and advanced competencies. And though some of the content from one certification to another is necessarily overlapping, each offering is targeted to meet the particular needs of the individual and to establish his or her qualifications. Getting certified and holding multiple certifications demonstrates that you take your career seriously. Simply put, the IFPS is there for you and the advancement of your career and can be the key component to increasing your worth to your employer.

So, what exactly is a fluid power expert? It is the individual who can satisfactorily address the particular need at that moment and one who also has a demonstrable, broad base of knowledge. If you are well rounded in multiple aspects of fluid power, prove it. Take the time and make the effort to get certified in all of those areas. Then that expert can and will be you.

Lastly, are you an employer or manager asking yourself, “What can I get out of certification?” You can assure your customers that your employees possess an industry-wide accepted level of competence and that your mechanics, technicians, and engineers have the skills necessary to perform their tasks confidently, efficiently, reliably, and safely. It shows you encourage employee pride and are willing to invest in the development of their careers. Tell the world that as a business owner or manager, you care about the image your company and employees put forth and how it reflects on the larger fluid power, manufacturing, and service communities.

For more information on the many IFPS certification offerings, visit www.ifps.org. So now you might be thinking, “Okay, but why should I spend all of this money in training and certifying my employees and risk them leaving and going to the competition?” Well, I have some bad news for you. When it comes to the talent pool, the fluid power industry is in a crisis. The number of individuals coming into and staying in the industry compared with those leaving or retiring is strikingly disproportionate. If you don’t invest in the development of your employees, including in training and certification, you are inadvertently promoting the industry’s—and maybe even your own company’s—demise. At some point, it will not be a matter of if you lose that employee but just a matter of when.

In the words of the late-and-great motivational speaker and sales coach, Zig Ziglar: “The only thing worse than training an employee and having them leave is not training and having them stay.” On the subject of employee training and development, no truer words have ever been spoken.

ABOUT THE AUTHOR:

Rance Herren is the manager of hydraulic systems and controls for the Rig Solutions division of National Oilwell Varco in Houston, Texas. He has over 26 years of experience in the application of fluid power technology and holds 10 different IFPS certifications, including Certified Fluid Power System Designer and Master Technician. He can be reached at rance.herren@nov.com.