Choosing the Right Pneumatic Cylinder

By Glen Weis, Product Engineer, Parker Hannifin.

Today there are more sizes, styles, and shapes of pneumatic cylinders than ever, which complicates the task of choosing the right one for your application. Of the various decisions to make, specifying the right size cylinder is especially critical. An undersized cylinder could mean you won’t be able to perform the required task, while oversizing a cylinder wastes resources by using more air than is necessary and costs more for additional capacity that is not required.

There are multiple considerations when determining the best cylinder size. The most critical is the force required to perform the task. The cylinder extension force can be calculated by multiplying the effective surface area of the cylinder’s piston by the air pressure supplied to the cylinder. When retracting a double-acting cylinder, the piston rod takes a portion of the effective surface area, and you need to subtract the area of the piston rod from the area of the piston.

There are multiple considerations when determining the best cylinder size. The most critical is the force required to perform the task. The cylinder extension force can be calculated by multiplying the effective surface area of the cylinder’s piston by the air pressure supplied to the cylinder. When retracting a double-acting cylinder, the piston rod takes a portion of the effective surface area, and you need to subtract the area of the piston rod from the area of the piston.

After determining the amount of force needed, it’s important to add in a safety factor. With a plant full of machines running at the same time, total air pressure demands in the plant may exceed availability, creating an occasional drop in air pressure. That’s one of the reasons why a safety factor is suggested, typically about 25% above the amount of force you anticipate needing. This ensures you have the force you need even if air pressure fluctuates within the plant. The additional capacity also allows for changes in the application.

Other considerations affecting size and model selected

Beyond calculating how much force you’ll need for your operation, other considerations when sizing a pneumatic cylinder include:

Stroke length. The length of your stroke could be as short as 1/16 of an inch to 100 or more inches. Many cylinders can be ordered in exactly the stroke needed for a particular application. Some cylinder offerings are produced in finite stroke lengths that are sometimes stocked by the manufacturer for immediate delivery.

Space limitations. The physical space available for the cylinder in the application is an important consideration. Cylinders are offered in various industry standard envelope sizes defining the physical size and shape of the cylinder. ISO and NFPA publish standards that manufacturers follow. Some cylinder lines are unique to a manufacturer and not defined by a standards organization.

Speed. How fast does your cylinder need to extend or retract? At high speeds, choosing a cylinder with adjustable end-of-stroke cushioning allows for higher speeds than without cushioning. Cylinders are limited in their kinetic energy absorption ability. A cylinder used beyond those sustainable limits will likely lead to premature failure of the cylinder. That’s why many cylinder manufacturers, like Parker, publish kinetic energy rating charts to allow machine designers to confirm this important aspect of cylinder selection. The greater the moving mass and speed, the more energy absorption capability that is necessary. The mass includes not only the piston rod assembly but anything attached to the end of the piston rod.

Noise. Cylinders with end-of-stroke bumpers are quieter. Many cylinder manufacturers offer bumpers for the extend and retract strokes. Bumpers are generally in the form of a rubber stop. Principally they reduce noise and offer end-of-stroke cushioning. Government agencies and other groups routinely express concerns over hearing loss in plant operators from exposure to industrial noise. Bumpers may help reduce noise levels in the plant in compliance with local regulations.

Available air pressure. Most plants typically have between 80 and 120 psi (5 and 8 bar) air pressure available. It’s important to match the rating of the cylinder with the amount of air pressure available. Typically, cylinders are rated for use up to 150 psi (10 bar), although some standard cylinders are rated to 250 psi (17 bar).

Considerations beyond size

Once you’ve chosen the right cylinder size, you can turn your attention to the myriad options available today. Most cylinders on the market today are aluminum with chrome-plated steel piston rods that resist corrosion. There are also heavy-duty steel cylinders appropriate for applications that may require additional durability, like for use in steel manufacturing and other harsh environments. Here are a few other choices:

Compact cylinders. These are ideal for applications that require less force and have limited space available. Parker recently introduced its P1P Series, a complete range of compact cylinders for these types of applications.

Single-acting cylinders. Although most cylinders are double-acting, meaning the power stroke is in both directions, single-acting cylinders are ideal when thrust is needed in only one direction. The inactive end is vented to the atmosphere through a breather or filter. Spring force or gravity returns the cylinder. This can simplify and lower the cost and complexity of control valves and logic. Cylinders can be ordered with spring extend or spring retract depending on the application requirement. The spring is internal to the cylinder and will require additional cylinder body length to accommodate the spring components. The spring component design and configuration generally limits stroke length to about 6 inches.

Double-rod cylinders. Double-rod cylinders are used when equal displacement is needed on both sides of the piston or when it is mechanically beneficial to couple a load to each end. The extra end can be used to mount cams for operating limit switches, and so forth.

Guided cylinders. Tools that need a specific orientation require a cylinder that prevents rotation. Guided cylinders are mounted in a housing that has guide rods and a tool plate. They are in widespread use in applications involving lifting, pressing, pulling, separating, controlling product flow, and many other applications. Guided cylinders can tolerate the catalog-defined side load rating, whereas a standard cylinder, not mounted in a guide unit, can withstand little to no side load.

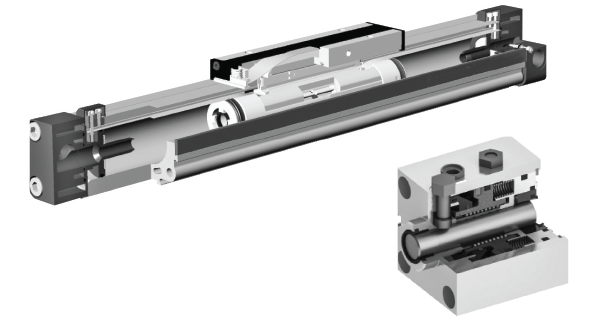

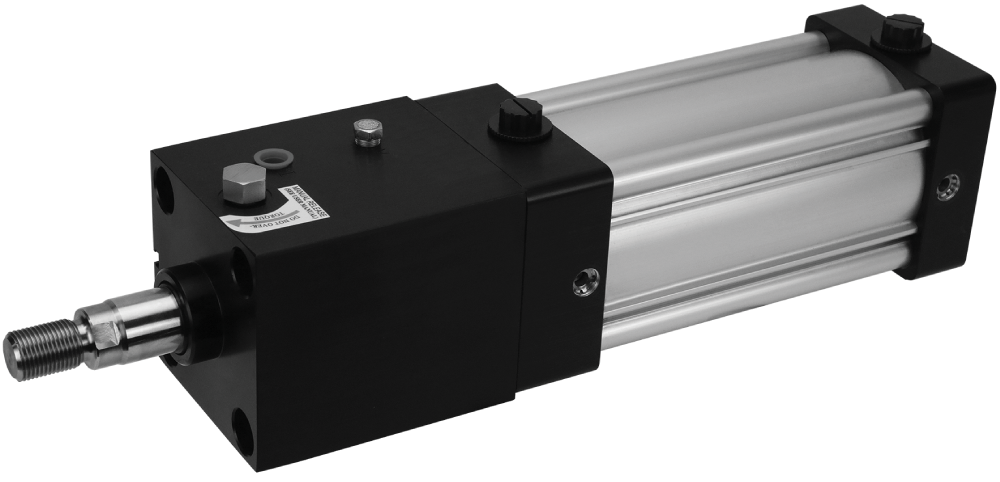

Rod locking cylinders. Safety is always a priority. Rod locking cylinders can be used to increase safety in the case of compressed air supply failure. For static applications, they can activate to provide emergency holding strength during a power outage or accidental disconnection of the air supply. These cylinders lock in place when air pressure drops, minimizing potential injury to operators and possible harm to equipment. Some manufacturers also offer dynamic rod locks that slow and stop the piston rod when a safety interlock is triggered. Due to their unique design, these types of cylinders require additional pneumatic controls, and more space and length.

Rodless cylinders. Designed to maximize stroke length in relation to overall cylinder length, rodless cylinders are compact to effectively save space. Instead of using an extending piston rod to move loads, they have a carriage directly coupled to the piston. The carriage moves in parallel with the piston and the same force is generated in both directions. Without a piston rod there is no subtraction of the piston area due to the piston rod diameter. It has the same effective piston working area in both directions. Benefits of rodless cylinders include:

- High load and moment capability.

- Load and moment capability that can be easily increased with guides on the cylinder.

- Various integrated brake options.

- Ability to be used for multi-axis pick and place.

- Smooth operation with low noise levels.

Sizing other components

Size matters when optimizing the performance of a pneumatic system. Valve sizing, for example, is greatly influenced by the flow requirement. How quickly the cylinder extends and retracts greatly influences the flow requirement. A larger cylinder with a longer stroke requires more air flow, which means a larger valve with a greater flow rating will be necessary. The number of cycles per minute (determined by output rate) also affects air flow which, in turn, affects hose and valve selection, and air preparation requirements for filters and point-of-use regulators. Proper air filtration will ensure a longer, more efficient life of the pneumatic cylinders.

Since the sizing of multiple components within a standard pneumatic system is so critical and complex, Parker created its Virtual Engineer online tool, which aids in the selection of the right products. As previously mentioned, the correct component size impacts the overall performance and cost of a pneumatic system. While sizing is often a consideration when building a new line, many plants could benefit from an audit that could determine, among other things, if downsizing is an option when components need to be replaced. Don’t simply assume you need the same size cylinder, valve, or filter, especially after changes in the line.