Roth Hydraulics Accumulators Essential to Bühler Die-Casting Machines

With the Carat 840 and the Carat 920, Bühler, of Uzwil, Switzerland, is further expanding its range of die-casting solutions. They are the most powerful machines of their kind in the world. The company is thus responding to the increasing demand from the automotive industry for machines to produce ever larger components.

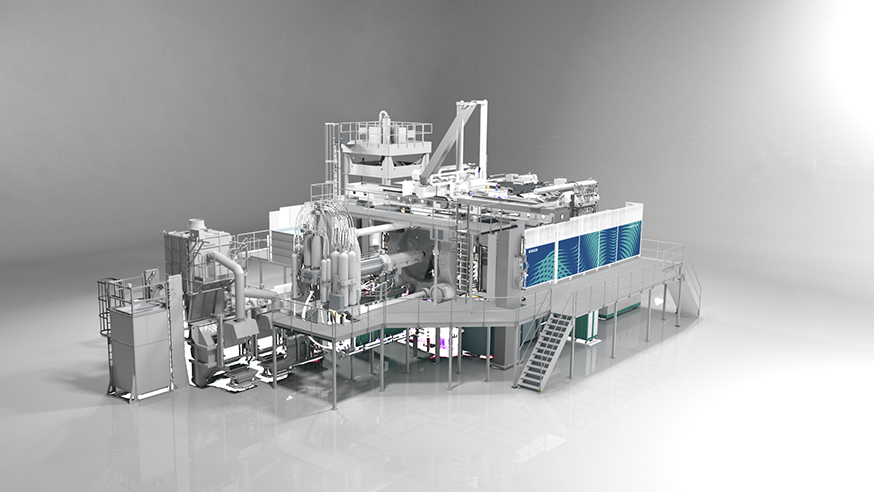

The Carat 920 die-casting machine from Bühler.

An important part of the new machines are the hydraulic accumulator systems from Roth Hydraulics, of Biedenkopf, Germany. They enable high component quality and ensure reliable and energy-efficient casting forces for the machine.

Automobile manufacturers are breaking new ground in production. New production processes with high clamping forces are required for the manufacture of large-format and complex aluminium components for car bodies, for example, to produce front or rear underbodies for vehicles. The new Carat 840 and Carat 920 die-casting machines from Bühler make such production solutions possible. The central component here is an extremely powerful and precise injection unit with uniform clamping force application. To reliably meet this requirement, Bühler decided to use a pressure accumulator system from Roth Hydraulics. It is the drive of the casting unit, which decisively generates the component quality and ensures a permanently reliable performance.

Powerful and dynamic casting unit

The demands on the accumulator system are many sided. On the one hand, the new solutions require a larger amount of stored energy, and, on the other hand, an extremely fast power development in order to ensure the necessary dynamics of the injection unit. The Carat 920 casting unit, for example, develops 2,130 kilonewtons of dynamic casting force and 5,340 kilonewtons of solidification pressure. The special challenge here is to enable around 1.5 meters of piston stroke within 100 milliseconds in the second phase of the casting process. The acceleration of the entire system including liquid aluminium is practically from zero.

“The Carat 920 can inject more than 200 kilograms of liquid aluminium into a mould within milliseconds,” said Michael Cinelli, product manager of Bühler Die Casting. “In doing so, it holds the mould together with a force of 92,000 kilonewtons. That’s as if the entire Eiffel Tower, with its weight of around 9,000 tons, was pressing on the mould.”

The Roth Hydraulics hydraulic accumulator manages this production task with ease and high precision. To achieve such solutions, the experts from Bühler and Roth Hydraulics have been cooperating for many years.

“The many years of cooperation in component development with Roth has always made it possible to quickly develop new solutions and further develop existing technology,” Cinelli said. “The joint focus is always on the end customer and the required reliability of the components.”

The Carat 920 die-casting machine from Bühler.

The largest die-casting machines in the Carat series are as big as a house. They are eight meters (26 feet) high and stand on a floor space of around 100 square meters (1,076 square feet). In addition, the Carat’s two-platen technology features a patented and stiffness-optimized platen design for uniform clamping force application, ensuring minimal platen deflection and high dimensional accuracy of castings. In combination with Bühler’s unique real-time controlled casting unit and DataView control, the Carat offers the highest casting dynamics and quality.

The enormous power density of hydro storage systems as well as the precise release of energy in the right quantity and at the required time in die-casting production saves electrical energy and significantly reduces the required connection power. In addition, the use of recycled aluminium or aluminium obtained through renewable energies enables the potential of CO2-neutral production. As a component of the entire production chain, this improves the ecological footprint of the end product, in this case, the vehicle.

Bühler’s vision for the future of the die casting industry is 0% scrap, 40% less cycle time, and 24/7 availability. The larger the castings, the greater the leverage for reducing production costs by reducing cycle time and scrap and increasing availability. Bühler is a pioneer with machines for the production of large die-cast parts and the world market leader in this segment. The Roth family company is also a world market leader in the segments of energy storage systems, composite technologies, and surface heating and cooling systems.

“Family-run companies pursue similar values and focus on personal customer relationships,” said Frank Fuchs, managing director of Roth Hydraulics. “We are pleased and proud that we have been cooperating with Bühler on this basis for many years. The use of our hydraulic accumulators in the new Carat range underpins our successful partnership.”

Roth Hydraulics offers energy-efficient hydraulic accumulator solutions for technologies in which hydraulic energy needs to be stored or converted. The fluid technology components are not only used in die-casting machines but also in energy and power plant technology, mobile hydraulics, and oil and gas technology. Roth Hydraulics is a traditional company in the industry with a history of almost 80 years and known under the previous company name Bolenz & Schäfer. As a full-range supplier, Roth Hydraulics provides a complete technology range with piston, bladder, and diaphragm accumulators as well as accumulator systems for a wide variety of applications. Know-how and experience in the development and production of piston accumulators make the company a true specialist. Roth storage systems are designed according to a modular principle. Depending on the requirements, the manufacturer implements customized and economical solutions, as in this case for the family-owned company Bühler.

For more information, visit www.roth-industries.com/en/default.htm.