Clean Fleet® Reduces Emissions by 99% at Hydraulic Fracturing Sites

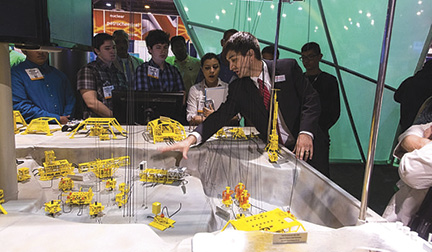

U.S. Well Services unveiled historic results from its newly patented Clean Fleet® technology (U.S. Patent No. 8,789,601). The hydraulic fracturing technology, recently implemented by Antero Resources, has demonstrated environmental gains, as well as significant cost savings for oil and gas exploration companies. The technology is proven to successfully decrease emissions by 99%, decrease sound pollution, and show operational cost savings to upwards of $40,000/day. The technology has been in use in the Marcellus Shale Play in West Virginia at sites operated by Antero Resources.

Clean Fleet® incorporates existing industry equipment configured to provide fracturing services with enhanced safety features, smaller physical and environmental footprints, and reduced noise levels at a lower cost relative to traditional fracturing equipment. It is a fully mobile, fully electric hydraulic fracturing system powered entirely by natural gas, whereby conventional diesel engines are totally replaced by electric motors. The technology

- uses electricity produced by on-site turbine generators fueled by field gas, reducing fuel-operating costs by 80%;

- mitigates environmental exposure by reducing NOx and CO emissions by 99%;

- eliminates 25 diesel truck deliveries to the well site for an average horizontal well completion, reducing traffic within communities while also mitigating associated fire hazards;

- reduces noise pollution emanating from the well site, making the workplace safer and communities undisturbed; and

- incorporates advanced technology that reduces equipment and discharge ion vibrations by 80%, resulting in fewer failures and safer operations.

The Clean Fleet® offered by U.S. Well Services consists of 14,500-psi technologically advanced hydraulic fracturing fleets manufactured by Stewart & Stevenson Manufacturing Technologies. The fracturing fleets are equipped to perform all aspects of pressure pumping operations.