Damage Control: Managing Fluid Contamination in Mobile Hydraulic Systems

By Tom Fistrovich, OEM and Mobile Market Business Development Manager,

Des-Case Corporation

For companies that rely on mobile equipment as part of their normal operations, reduction in both downtime and overall maintenance costs is imperative to maintaining fleet efficiency and profitability. The harsh environments in which mobile equipment is typically used can make these reductions extremely challenging. On the drive side, there is an increasing trend toward electric drive versus conventional diesel powered. However, hydraulic systems continue to be a critical component in mobile equipment. While there are many aspects to maintaining a reliable hydraulic operation, contamination ingression in the form of particles and moisture is a major source of poor reliability, leading to underperformance, component damage, and hydraulic system failures.

Mobile equipment can be used and operated in some of the most challenging and contaminated working environments, including mine sites, agricultural plots, steel mills, oil fields, and many other applications. They all have one thing is common: unplanned downtime due to contamination affects operational efficiency and throughput, ultimately reducing the bottom line. Unfortunately, operating in these contaminated environments is unavoidable. Consumer demand for natural resources and products manufactured on these work sites continually increases.

But there is a way to reduce the negative impact of contamination on hydraulic systems in mobile equipment.

Most fluid power experts recognize that particle contamination is responsible for as much as 80% of mechanical machine wear in hydraulic systems. In light of these challenges, improving overall system cleanliness reduces hydraulic system failures, helping to increase equipment reliability while reducing the costs associated with maintenance and downtime. Fortunately, there is a surefire way to achieve this. Proactive maintenance of hydraulic fluid can extend the system life as much as five times. Extending hydraulic fluid and system life extends the time the mobile equipment is in use and doing its job.

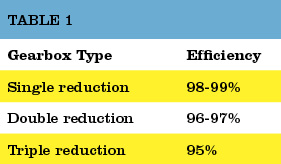

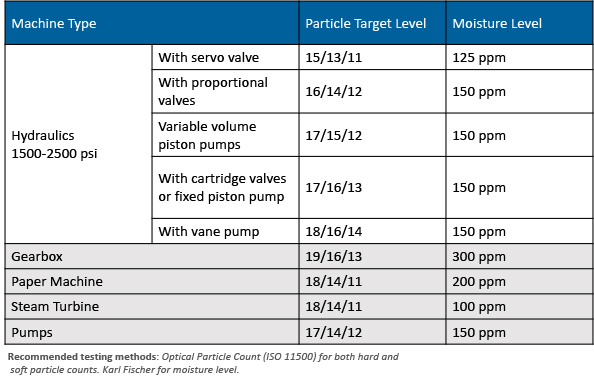

Figure 1: Fluid cleanliness target levels. (Recommended testing methods: optical particle count [ISO 11500] for both hard and soft particle counts; Karl Fischer method for moisture level.)

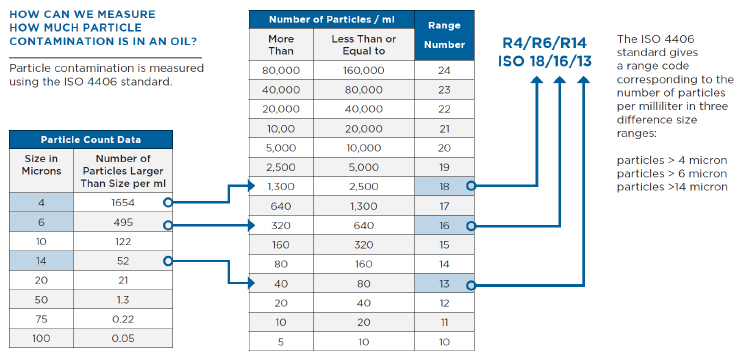

Figure 2: Measuring particle contamination in an oil.

Setting a strategy

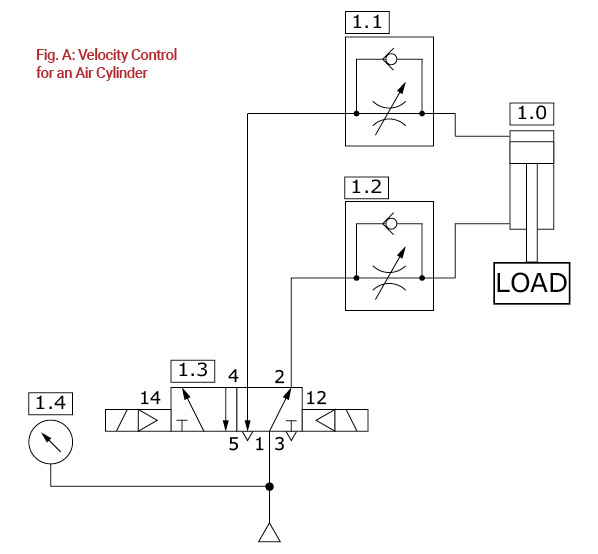

The first step is to establish a maximum target for fluid cleanliness using ISO 4406 or a similar fluid-cleanliness standard. Based on the sensitivity of hydraulic components like pumps and valves, different components can tolerate varied amounts of contamination. Knowing the sensitivity level allows equipment manufacturers and users to set target cleanliness levels. In fluid power systems, hydraulic pumps, motors, and valves typically drive the cleanliness requirements of the system, as these components are very sensitive to contamination and deposits. As shown in figure 1, a hydraulic system using a vane pump is less sensitive to the concentration of particle contamination than a system using a variable volume piston pump. Furthermore, the addition of servo valves to the system makes it even more sensitive to particle contamination. Knowing which components exist in your hydraulic system allows you to set a baseline cleanliness level at which the system should operate. A precision fluid contamination control strategy strives to achieve and maintain these baseline contamination levels.

Once the user determines a target cleanliness level, the next step is to consider a strategy to control the contamination and maintain system cleanliness to the target levels. A precision fluid contamination control strategy is the most holistic method to achieve and maintain the target levels. This method of proactive maintenance revolves around four areas:

• Contamination prevention – sealing and protecting the system

• Contamination removal – cleaning and purifying the fluid system

• Fluid assessment – visual assessment and review of the fluid during operation

• Fluid monitoring – using condition-based monitoring to diagnose fluid condition and contamination levels

Contamination prevention. Studies show that contamination exclusion in a system can cost 10 times less than contamination removal in the same system. This is one driving factor for implementing the first state of a precision strategy: contamination prevention. Mobile hydraulic systems have many points that potentially allow contamination ingression into the system. Common ingression points include the hydraulic cylinders and reservoirs. While contamination ingression at the hydraulic cylinders typically happens during operation or washdown, it is common for the hydraulic reservoir to experience contamination ingression during operation and service intervals.

Contamination prevention in a hydraulic system starts with assuring that the system’s hydraulic fluid meets the recommended ISO 4406 target cleanliness level. Hydraulic fluids can become contaminated even before they arrive on site. In fact, every transfer of the fluid can double its contamination level. New hydraulic fluid should be filtered prior to adding it to a system because most new hydraulic fluids are up to 16 times dirtier than typical cleanliness targets (see figure 2). Users should verify that they are adding the correct fluid to prevent cross-contamination. Whether the hydraulic fluid is stored in bulk tanks, left in drums, or stored into intermediate bulk containers, the storage system and dispensing equipment should be equipped with some level of loop filtration to continually clean the fluid when filling, recirculating, and dispensing it. Mobile filtration carts are an excellent choice for servicing on-site mobile equipment hydraulic fluids, as they offer the necessary fluid filtration and the convenience of mobility.

Figure 3: Airflow of a desiccant breather.

In a hydraulic system reservoir, one common point of contamination ingression is the breather. Breathers are a necessary component in many hydraulic systems to allow air to freely flow in and out of the system as fluid levels change or thermal expansion or contraction causes air exchange. Most standard breathers offer a pleated filter to prevent particle contamination. These breathers are generally limited to exclusion of contamination particles of about 20-40 microns absolute. Some hydraulic components can experience damage from particles under 2 microns. Additionally, standard pleated breather filters do not typically address the risk of moisture ingression, which can enter through the breather due to moisture or humidity in the operating environment. It can also develop in the reservoir’s headspace due to repeated changes in relative humidity.

To address moisture and particle contamination during operation, users should consider desiccant breathers for all hydraulic reservoirs. Desiccant breathers work by filtering particle contaminants and absorbing moisture when the breather inhales air (see figure 3). Desiccant breathers also help remove moisture from the reservoir’s headspace through designs that keep the desiccant in constant contact with it.

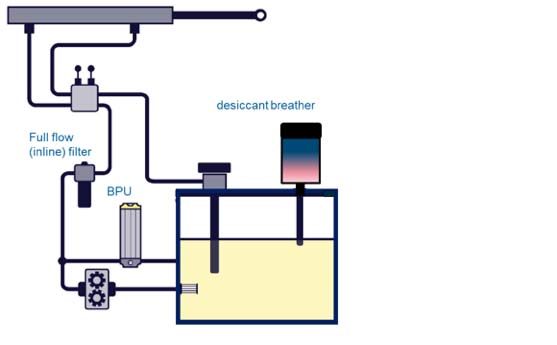

Contamination removal. Even after taking the proper steps to prevent contamination, it will inevitably enter a hydraulic system at some point in the operational life. This is why hydraulic systems on mobile equipment typically employ some level of filtration through the pressure and flow of the system. Common filtration setups consist of an in-tank strainer or suction filter screen, filtration on the system’s pressure side, and a return-line filter to clean the fluid as it returns to the reservoir. However, these components by themselves are often insufficient to maintain optimum levels of fluid cleanliness.

One very efficient and effective way to improve cleanliness levels is with a kidney loop filtration system, which is typically set up as an off-line system and consists of its own motor, pump, and filter elements. Off-line kidney loop systems can be set up on mobile filter carts and incorporated into a work site’s preventative maintenance. While the kidney loop is one of the most efficient ways of removing contamination, mobile equipment is typically limited to using it when the equipment is idle or being serviced. But the goal of precision contamination control strategy is to reduce mobile equipment’s idle and service time. Kidney loops also do not clean the fluid in the hose cylinders and valve blocks as the machine sits idle.

There are, however, options that function as a kidney loop filtration system and are specifically designed for mobile equipment. An example is a bypass filtration system. Bypass units take advantage of hydraulic system pressure and flow by bleeding 5% to 10% of fluid from the main hydraulic system, often via a pilot circuit, and passing it through one or more filter elements before the clean fluid returns to the reservoir (see figure 4). Since a bypass filter is not part of the main fluid flow path, bypass filters can be installed with high filtration efficiency, often exceeding a filtration beta rating of 2,000 at 3 microns.

Assess and monitor. To ensure that contamination control measures are effective, regular routine fluid analysis is critical. Sampling oil monthly or every 1,000 operating hours – whichever comes first – should include not just basic oil analysis but also confirmation that contamination levels are meeting the ISO 4406 standard. Users should investigate levels above the defined targets and take corrective action as soon as possible.

Another tool is condition-based monitoring, which provides feedback on sudden changes in the fluid and indicates a need for service or replacement. For example, users can integrate an oil-quality sensor into the hydraulic system to alert for oil degradation and provide the amount of remaining useful oil life. Pairing condition-based monitoring with an oil-sampling strategy can extend maintenance intervals, improve equipment reliability, and reduce the need for costly fluid changes, unplanned downtime, waste-fluid costs, the carbon footprint, and the overall cost of ownership. Many condition-based monitoring sensors are now available as connected IIoT solutions, allowing for remote monitoring and diagnostics of mobile equipment.

Maintaining the strategy

As you develop and implement a precision fluid contamination control strategy, it is extremely important to document it. Documenting the strategy and how to carry out the maintenance and inspection for each step helps create uniformity and consistency in the process. It provides the framework for work instructions to which team members can refer and ensures they are maintaining the strategy. Teams can then take the following steps to set the precision fluid contamination control strategy in place.

Figure 4: Bypass filtration system.

• Set the ISO 4406 target cleanliness levels.

• Prevent contamination from entering the hydraulic system.

• Remove contamination that may have entered the hydraulic system during operation.

• Visually assess the hydraulic fluid and overall system condition during operation and idle time.

• Monitor the hydraulic fluid in real time with condition-based monitoring.

Documenting a process associated with each of these steps improves the reliability of mobile equipment hydraulic systems, reduces unplanned downtime, and ultimately increases operational efficiency and throughput. Committing to a precision fluid contamination control strategy with proactive maintenance should improve the bottom line.