Determine Correct Hose Replacement by Measuring Existing Assembly to Make a Duplicate

How to measure hose assemblies and how to measure cut-off length.

Once the proper hose and fittings have been selected, the assembly can now proceed.

Components, equipment and procedures will vary for all types. However, measuring, cutting and fitting orientation procedures are the same for the styles of fittings:

- Permanent crimped

- Permanent swage

- Field attachable

Measuring Hose to determine hose cut-off length:

With some assemblies, the length must be within tight tolerances for proper installation. This is especially true for short, high pressure hose assemblies. If a hose assembly is shorter than the manufacturer’s recommended length, the likely result will be hose separation failure.

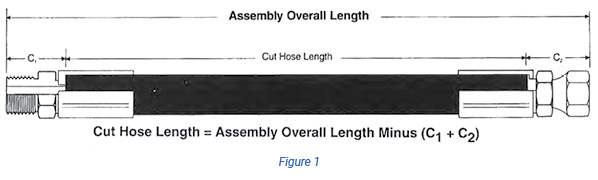

Note: Before cutting the hose, make sure you understand the difference between cut hose length and overall assembly length (OAL).

The hose cut length for a hose assembly is calculated by subtracting the cut-off factor (distance from the bottom of the ferrule or collar to the end of the fitting, dimension “C” in Figure 1). Typical length tolerance: Up to and including 300mm, ± 3mm (12”, ± 0.13in), up to 450mm, ± 5mm (18”, ± 0.19in), up to 900mm, ± 7mm (36”, ± 0.25in), over 900mm (36”) ± 1% of length.

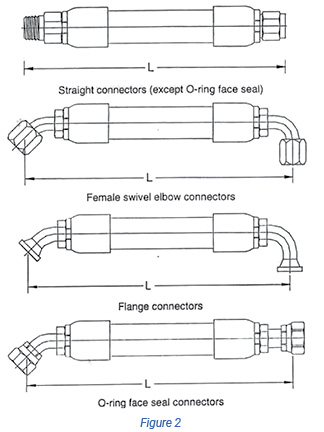

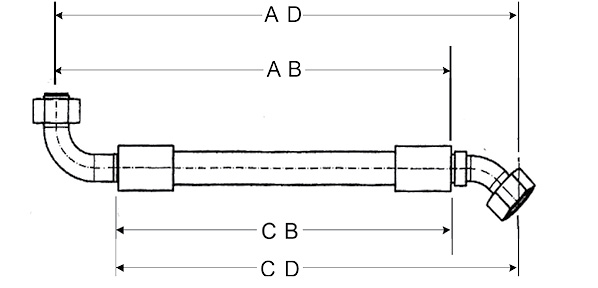

Unless otherwise specified, assembly length shall be the overall length measured from the extreme end of one fitting to the extreme end of the other, except for o‑ring face seal type fittings which shall be measured from the sealing face. Where elbow fittings are used, measurement shall be to the centerline of the sealing surface of the elbow end. (The sealing surface of female flared elbow fittings shall be the centerline of the outer end of the cone seat.) See Figure 2 examples of OAL measurement on the next page.

Unless otherwise specified, assembly length shall be the overall length measured from the extreme end of one fitting to the extreme end of the other, except for o‑ring face seal type fittings which shall be measured from the sealing face. Where elbow fittings are used, measurement shall be to the centerline of the sealing surface of the elbow end. (The sealing surface of female flared elbow fittings shall be the centerline of the outer end of the cone seat.) See Figure 2 examples of OAL measurement on the next page.

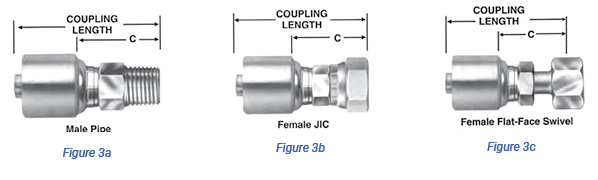

For male thread fittings (Figure 3a), the cut‑off is measured from the locking collar to the end of the threads (C) as shown.

For straight female fittings (Figure 3b and 3c), the cut‑off is measured from the locking collar to either the end of the nut or seat depending on whether the nut can be pulled back exposing the seating surface as shown.

All cut‑off values are identified in the fitting tables found in the manufacturer’s catalog.

Test Your Skills

1.What is most important when determining “cut-length”?

a. That fitting length be included

b. Fitting orientation

c. The overall length (OAL) varies depending on the fitting

d. Determine the cut-off length for the fitting

e. Know the difference between cut hose length and assembly overall length

2.Which dimension is the OAL on this diagram?

a. Line segment AD

b. Line segment AB

c. Line segment CB

d. Line segment CD

e. None of the above

See the Correct Solutions

- e, 2. a