Cable Puller Motor Speed Problem

By Robert Sheaf, CFPAI/AJPP, CFPE, CFPS, CFPECS, CFPMT, CFPMIP, CFPMMH, CFPMIH, CFPMM, CFC Industrial Training

A contractor for a power and light company was hired to pull new wires and cable needed for a new plat of homes being built. The hydraulic puller unit incorporated a small gas engine and pump assembly to rotate a hydraulic motor with a rope attached to the cable they were pulling. The unit would pull enough cable to reach the next power pole plus extra to reach the ground. They would stop the pulling, disconnect the rope from the cable, thread the cable over the next pole, and down to the puller that was moved to the next position.

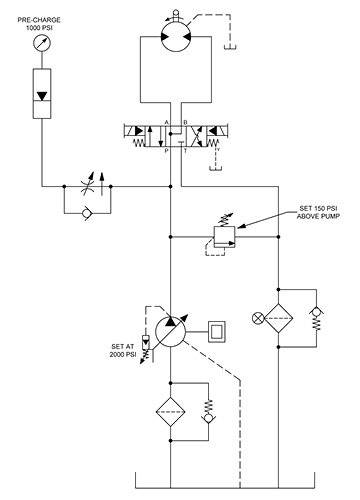

The pump would recharge the accumulators (only one shown on the circuit), while the unit was moved to the next position. The accumulator and pump would wind the rope up at a constant speed based on the accumulator’s flow control setting.

On one of the pulling cycles, the motor speed increased to a high rate decelerating down to a slow rate. The team checked the accumulator pre-charge and re-adjusted the flow control several times and the motor would still start off at a high speed and ramp down to a slow speed.

Any idea what is causing the problem?

See the Solution

The pressure compensated flow control should only allow a fixed rate of oil to pass regardless of the accumulator’s outlet oil pressure. The hydrostat inside the PC flow control was stuck in the open position rendering the flow control as a normal orifice that changes flow if the inlet or outlet pressure changes.

If you have any questions about the details, please contact Robert Sheaf at rjsheaf@cfc-solar.com.

When they disconnect and reconnected the motor spun fat because of no load .once the load was induced again the speed slowed down..A direct check needs to be installed to keep the pressure in the line during repositioning.

Check the bladders in the accumulators. If the bladders are ruptured you can still precharge them in this circuit ( hoses to motor and all accumulators will fill with nitrogen). When the valve is turned on the nitrogen will expand as it went thru the motor. Once the N2 is gone the system would run slow (depending on the flow rate from the pump).