The Digital Revolution of Electrohydraulics

By Fabio Balzarini, Technical Sales Manager, Atos Spa.

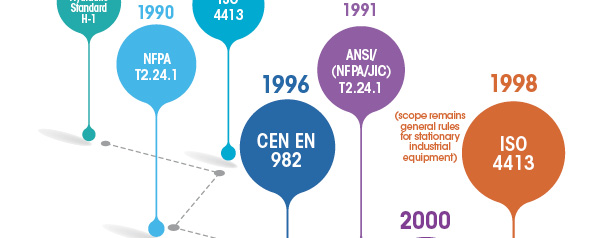

The Journal is celebrating a 25-year milestone in 2019 and reflecting on how far the industry has come since the birth of the magazine. This new column is dedicated to showcasing the growth of fluid power technology. Each article features a product or industry analysis and how it has transformed from its early years. If you have a product or analysis to share with the Journal readers, please contact Candace Nicholson at cnicholson@fluidpowerjournal.com.

Everyone can see how digital has changed our lives. Similarly, the industry sector, with the advent of the fourth revolution, where thanks to smart components, the machinery manufactured today will produce components for the market of tomorrow, will also change our lives.

Atos has always believed in the value of technology and is constantly looking for breakthrough innovations. So much so that it has become a pioneer of digitalization. Atos was the first company to offer digital electrohydraulic components on the market, with on-board diagnostics, which are completely manageable via fieldbus from the machine control unit.

At Atos, innovation is made every day with courage and determination, introducing new technologies that paved the way for further solutions that would not have been previously possible.

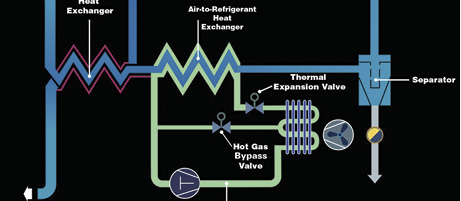

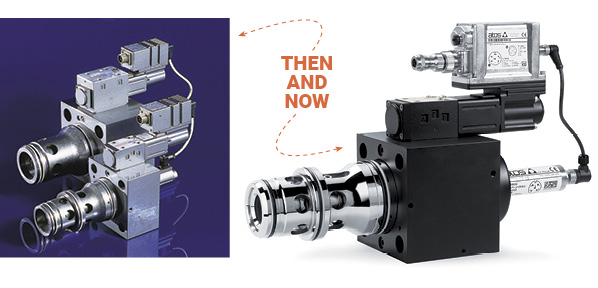

The first step of this long journey was to move the analog electronics on-board to the valve. We then made it digital, integrated diagnostics, and finally made it communicate with the machine control unit. Small steps have been made to make the valves more intelligent. At the same time, Atos transformed the components into a source of valuable data that was previously inaccessible with the analog electronics. The analysis of the information gathered has stimulated the development of new control strategies, which have significantly reduced valve response times, and inspired a new approach for hydraulic applications.

Later, the technology evolved with higher computing powers, larger memory, and faster communications, creating the opportunity to implement smart algorithms and features that are equipped in the valves.

For example, multiple dynamic configurations became a major asset to our customers. This allowed them to change the valves dynamic behavior in real-time, without interruptions of the working cycle. Such technological innovations helped develop industrial ethernet, which allows real time communication with the machine control unit; the internal oscilloscope, to monitor each phase of the cycle via USB/Bluetooth; and internal diagnostics, which saves the alarm history in the valve’s permanent memory.

In parallel, the mechanics evolved in various aspects. Thanks to the CFD (Computational Fluid Dynamics) analysis, it has been possible to optimize the components performance increasing the flow rates and working pressure up to 420 bar, while the extensive stress tests conducted in our research laboratories have allowed us to increase the mechanical resistance to shock up to 50 g and reach ingress protection levels against liquids and dust to IP66/67.

In the past, we have given great emphasis to increasing performance in terms of raising efficiency and productivity. Now there is a second aspect that is becoming increasingly important: functional safety. Atos is the only electrohydraulic manufacturer in the world to produce proportional valves, certified IEC 61508 up to SIL 2 / SIL3 and ISO 13849 up to category 4, PL e.

Atos will continue to invest in innovations as long as each project is a challenge and an opportunity to define new market standards.