Ensuring Proper Maintenance and Repair in Projects Involving an Elevated Height

By Donald Chilton, Director of Product Management for MANN+HUMMEL and its WIX Filters Brand

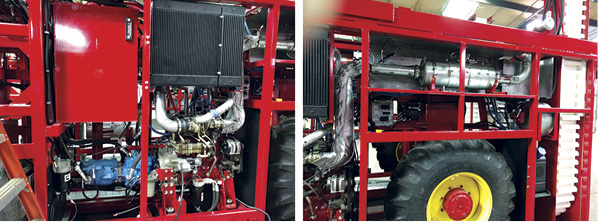

Any project that requires maintenance and repair at an elevated height may require a hydraulic system that can safely raise workers to the correct level for maintenance. A truck with a skylift, for example, may be the only way to access a tall building, electrical line, or wind turbine. These types of systems depend on hydraulic fluids to power many of their critical functions, such as platform lift, reach and leveling – no mean feat when you consider the size, scope and materials of the truck, and its lift. Trucks with skylifts are made of incredibly massive, heavy pieces of steel that include crane-mounted beds with cranes that can measure 60 feet long and are capable of lifting a person hundreds of feet into the air. Ensuring these machines operate at peak capacity is crucial, and ensuring the safety of those on them is of utmost importance.

One of the Factors in Ensuring Complete Safety is Proper Filtration Outfitting.

Skylift trucks require filters that will last and adapt to the trucks’ powerfully intense jobs and the incredibly rugged and dirty environments in which they operate. Heavy-duty hydraulic filters help ensure that fluids are kept clean, so that equipment dependent on those fluids can operate safely and efficiently. If contaminants such as dirt, dust or metal shavings pass through an engine, the engine will be damaged, potentially halting the entire system and operation. As these skylifts are frequently chasing various projects, it’s important to ensure these impurity levels are minimal no matter where the project is located. Filtration plays a critical role in protecting the system, as well as the lives of those individuals using the equipment.

“Proper filtration is important because some projects, like wind farms, are not always in the most “urban” environments. The last thing you want is a hydraulic system breakdown in the air because someone used the wrong part or wrong micron rated filter in the equipment.”

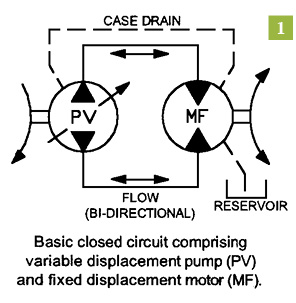

These heavy-duty skylift vehicles frequently house both a primary and a secondary hydraulic system for safety purposes, with many trucks requiring three filters per hydraulic system – suction line filters, pressure line filters, and return line filters. In addition to the truck’s filtration system, some elevated projects themselves, such as wind turbines, require their own hydraulic systems. With both, maintenance is key.

“Trucks with skylifts need to have reliable and safe operation, and they also need experts that can identify the needs for each filtration point. You will find filtration products that come in many micron sizes from 3 to 150 depending on the need of the equipment and location.”

Proper Filtration Also Contributes to Better Business Practice.

By outfitting their machines with the right filters, business owners are able to lower their long-term costs by extending maintenance intervals without sacrificing performance. Optimizing these change intervals extends the life of fleets and helps to ensure optimum uptime, ultimately saving both time and money. In addition, equipping machines such as skylifts with filters that have been tested and proven to withstand off-highway conditions ensures both machine efficiency and, most importantly, the safety of all involved.