Festo Launches Configurator, Smart Positioner

Festo launched several new products earlier this month at the Automation Fair in Houston.

Festo introduced the KDFP online configurator for quarter turn actuators. Engineers select the size and easily, quickly, and reliably order the actuator via the configurator. KDFP actuator options include a pilot valve, positioner, position indicator, position feedback, and mounting adapters or reducing sleeves for mounting on the valve body.

The KDFP online configurator.

Festo now offers three process component online configurators: the KVZA for butterfly valves, the KVZB for ball valves, and the new KDFP for quarter turn actuators. These Festo configurators reduce the engineering time required for product specification from hours to minutes. Engineers simply enter application parameters into the tool and at the end of the configuration session receive a quote, ship date, configured product data sheets, and 2D and 3D CAD models.

Festo also introduced the CMSH smart positioner for process valves. This new smart device features HART communication.

The CMSH smart positioner.

Because of its high airflow rate, the CMSH is suitable for both large and small actuators in such applications as dosing, mixing, and filling. The CMSH offers extensive integrated functions for self-monitoring and diagnostics with clear recommendations for corrective action.

The CMSH is user friendly and simple to operate because of its large and rotatable plain-text display that can be read from various directions. The setup wizard makes it easy to commission. As part of this process, fast or robust control mode can be selected.

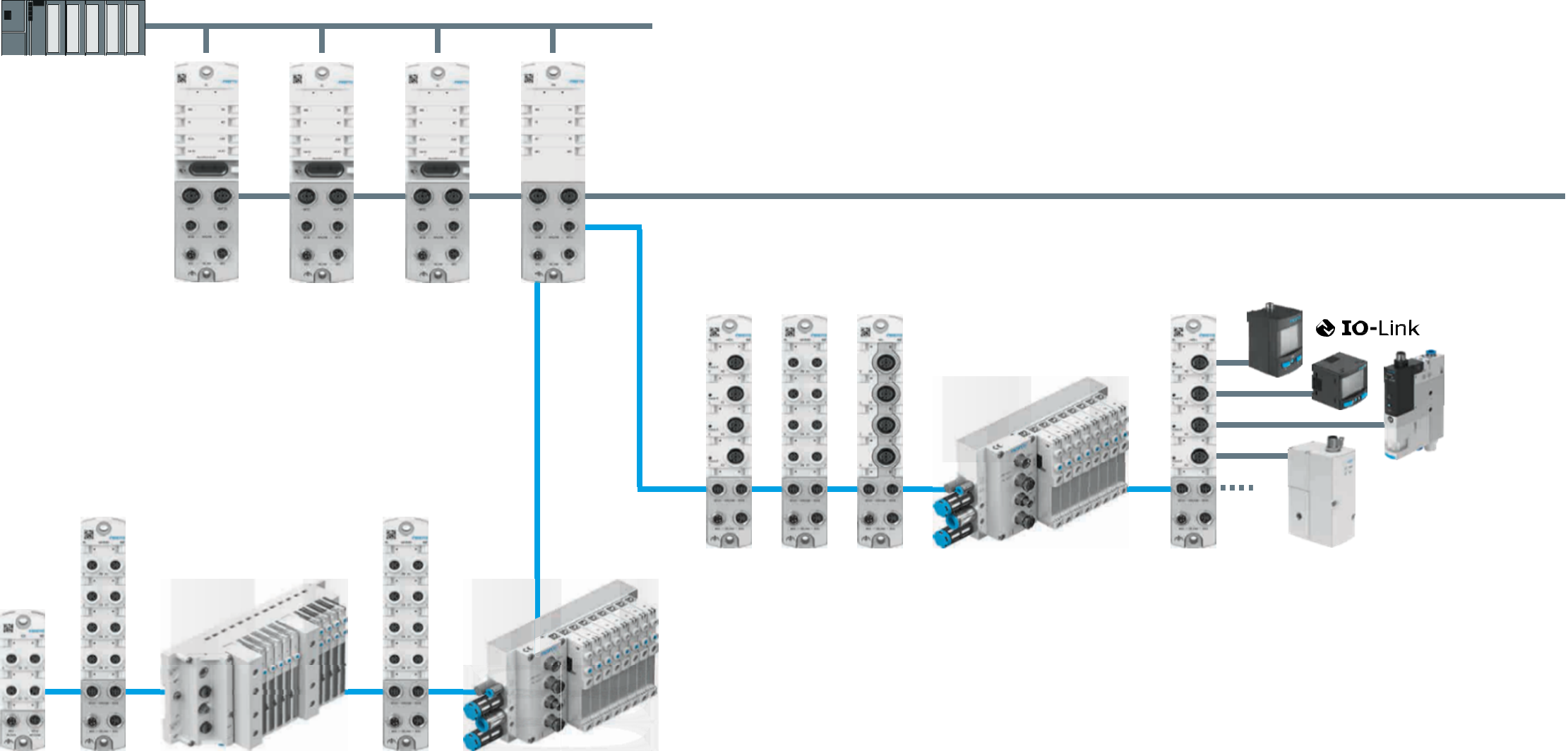

Festo also featured such process industry solutions as the VTSA-F-CB pneumatic valve manifold for PLd, (up to CAT 3 for PUS) safety; the CPX-MPA modular valve terminal for maximum valve flexibility; and decentralized I/O for less wiring, faster installation, and improved pneumatic system performance.

The CPX-AP-I decentralized I/O system.

The CPX-MPA valve terminal offers every standard valve function, including the cost/space saving dual 3/2 types. This is ideal for control of single acting process valves. Additionally, the VPPM can be used to control 3-15psi variable position valves. The combination of MPA and VPPM valves are electrically connected via a serial bus to EtherNet/IP, via the Festo CPX modular peripheral system. Using the CPX-MPA/VPPM valve terminal, OEMs can integrate on/off and variable position valves via a single Ethernet IP drop for less cost and quicker installation and startup.

The new CPX-AP-I decentralized I/O system offers plug-and-play installation of over 80 I/O modules (2k of data), with cable lengths of 50 meters between modules bringing valves closer to actuators and improving response time. The system can export an L5X file for easy commissioning and parameterizing of the I/O.

For more information, call 800-993-3786 or visit www.festo.us.