Flow Transmitters Enable Remote Monitoring of Flow Meters – Even in Hazardous Areas

By Chris Husson, Senior Design Engineer, AW-Lake Company

The Journal is celebrating a 25-year milestone in 2019 and reflecting on how far the industry has come since the birth of the magazine. This new column is dedicated to showcasing the growth of fluid power technology. Each article features a product or industry analysis and how it has transformed from its early years. If you have a product or analysis to share with the Journal readers, please contact Candace Nicholson at cnicholson@fluidpowerjournal.com.

Many industries implement flow meters to monitor the flow of liquids or gas during various operations to ensure accurate manufacturing processes while avoiding excessive costs. As some flow systems incorporate many flow meters, monitoring them can be labor intensive, taking hours for operators to travel to multiple locations and connect meters to get readings. Flow transmitters provide a continuous output of flow data that can be read by operators without the need for additional instrumentation. Some operate in hazardous environments, while others offer connection options to remote monitoring systems. AW-Lake Company even offers a battery-

Many industries implement flow meters to monitor the flow of liquids or gas during various operations to ensure accurate manufacturing processes while avoiding excessive costs. As some flow systems incorporate many flow meters, monitoring them can be labor intensive, taking hours for operators to travel to multiple locations and connect meters to get readings. Flow transmitters provide a continuous output of flow data that can be read by operators without the need for additional instrumentation. Some operate in hazardous environments, while others offer connection options to remote monitoring systems. AW-Lake Company even offers a battery-

operated version that works wirelessly.

But in the early days, the only displays available for flow meters were panel mount units requiring an external AC or DC power supply. Understanding the market need for simpler meter-mount displays not requiring expensive wiring, AW-Lake introduced the RT-EX2 Battery-Powered Flow Display in the 1990s, the first battery-powered flow monitor mountable on meters and operable in remote areas where power was unavailable.

Powered by a single D-cell Lithium battery with a four-year minimum battery life, the RT-EX2 offered long life and simple setup by entering a scaling factor for the rate and total screens to show values. If mounted in a hazardous or dirty environment, the unit included a magnet that enabled users to change readouts between the rate and total displays or to reset the totalizer without removing the cover and exposing the sensitive electronics to the environment.

Moving from a Monitor to Flow Transmitter

Using customer feedback and advances in technology and design ideas from its engineering team, AW-Lake made significant design improvements to the original RT-EX2 and introduced a new version called the RT-10 Battery-Powered Flow Rate Transmitter in 2006. Improvements in the sensor input circuitry increased the allowable maximum signal frequency from 800 Hz to 3000 Hz, extending the range of turbine flowmeters for use with the flow rate transmitter.

Where the RT-EX2 was just a monitor without any external signal connections, the RT-10 added a fiber optic output option, making it possible to send a 0-100Hz flow signal remotely. Also, a 4-20mA loop output option supported remote monitoring of the flow rate in addition to the local display.

In applications where flow rates appeared erratic, an added gate time filter provided the option to smooth the flow rate display as well as the 4-20mA loop output signal. To maintain a long battery life with the improved functionality and additional options, a programmable sleep timer put the unit in a low power state when no input frequency or button activation was detected after the programmable sleep time passed. To aid in preventative maintenance, the RT-10 also displayed a warning about low battery life so operators could schedule battery replacement at a convenient time rather than waiting until the battery died and the unit no longer worked.

Monitor and Program Flow Meters from a Smart Device

AW-Lake recently introduced its third generation of battery-powered flow monitors that mount directly on the meter with the RT-50. As many operators prefer to use smart devices in monitoring operations remotely, the RT-50 Battery-Powered Flow Rate Transmitter offers Bluetooth capabilities to view readings and adjust the rate, total, reset, or time on a smart device. A graphical multi-line display and improved front panel user interface buttons simplify reading flow rate or total while programming units. When using Bluetooth connectivity, users can connect to the RT-50 from a smartphone or tablet to create a wireless flow monitor that works in the palm of a hand.

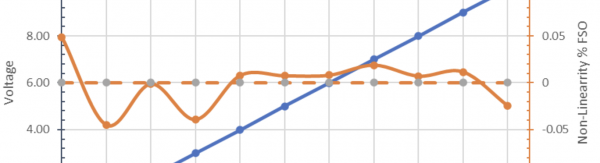

Other enhancements include a 10-point linearizer that improves the accuracy of any flowmeter, especially for applications where meters are used outside of their published specifications. Units also are programmable to store total values at a set time of day. A battery backup of totalizer values assures that data is not lost when replacing the battery.

Incorporating Wireless Sensing Technology with AW-Lake Flow Meters

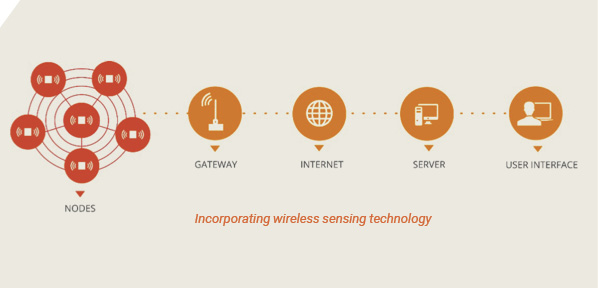

Many flow systems utilize a network of flow meters that requires wiring or daisy chaining a network of instruments by cable to a large interface panel. Cabling can cause a cascade of issues costly to repair. Using radio frequencies or Bluetooth communications, it is now possible to connect multiple sensors and flow meters into a secure mesh network that can be accessed remotely by personnel. Data from flow meters is extracted by a radio- or Bluetooth-enabled node and transmitted to a central gateway, which can interface with local WiFi networks to provide real-time flow data on demand.

Working with its sister company SignalFire Wireless Telemetry, AW-Lake can combine its flow transmitters with integrated wireless nodes that intuitively connect in a secure mesh for safe, real-time flow monitoring on the go.